Red bricks offer high compressive strength and durability due to their natural clay composition, making them ideal for load-bearing structures in building construction. Fly ash bricks, manufactured using industrial by-products, provide superior thermal insulation, reduced weight, and eco-friendly benefits, promoting sustainable building practices. Choosing between red brick and fly ash brick depends on balancing cost, environmental impact, and structural requirements of the project.

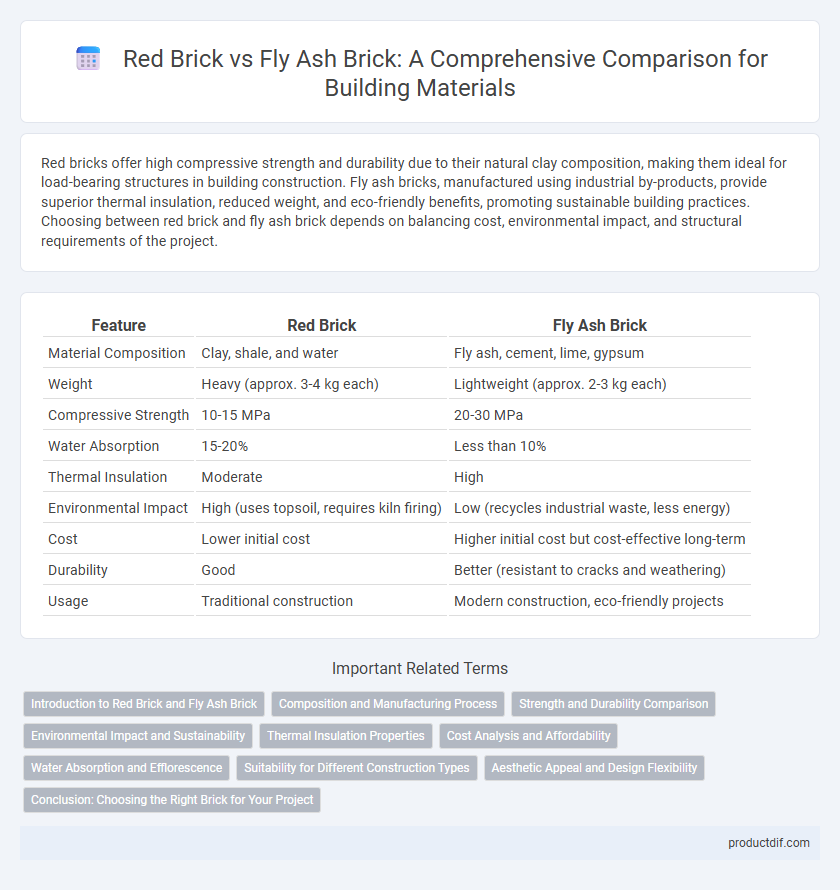

Table of Comparison

| Feature | Red Brick | Fly Ash Brick |

|---|---|---|

| Material Composition | Clay, shale, and water | Fly ash, cement, lime, gypsum |

| Weight | Heavy (approx. 3-4 kg each) | Lightweight (approx. 2-3 kg each) |

| Compressive Strength | 10-15 MPa | 20-30 MPa |

| Water Absorption | 15-20% | Less than 10% |

| Thermal Insulation | Moderate | High |

| Environmental Impact | High (uses topsoil, requires kiln firing) | Low (recycles industrial waste, less energy) |

| Cost | Lower initial cost | Higher initial cost but cost-effective long-term |

| Durability | Good | Better (resistant to cracks and weathering) |

| Usage | Traditional construction | Modern construction, eco-friendly projects |

Introduction to Red Brick and Fly Ash Brick

Red bricks, made from natural clay and baked at high temperatures, offer excellent strength, durability, and thermal insulation for construction purposes. Fly ash bricks, produced from a mixture of fly ash, cement, sand, and water, provide lightweight, eco-friendly alternatives with enhanced compressive strength and reduced water absorption. Both materials have distinct advantages in terms of sustainability, cost, and performance, influencing their selection in modern building projects.

Composition and Manufacturing Process

Red bricks are primarily composed of natural clay and shale, fired at high temperatures in traditional kilns, resulting in a dense and durable material. Fly ash bricks consist of industrial byproducts like fly ash, cement, lime, and gypsum, compacted using hydraulic presses and cured through steam or autoclaving, making them lightweight and eco-friendly. The manufacturing process of fly ash bricks minimizes environmental impact by utilizing waste materials and lower energy consumption compared to the energy-intensive firing of red bricks.

Strength and Durability Comparison

Red bricks, made from clay and fired at high temperatures, offer high compressive strength typically ranging from 10 to 20 MPa and exceptional durability due to their dense, hard structure. Fly ash bricks, produced by mixing fly ash, cement, and lime, provide comparable strength between 7 to 15 MPa and enhanced resistance to water absorption and chemical corrosion, contributing to long-term durability. Both materials exhibit strong performance, but red bricks are preferred for heavy-load structural applications while fly ash bricks excel in eco-friendly construction with good strength and durability.

Environmental Impact and Sustainability

Red bricks consume large amounts of clay and require high-temperature kilns fueled by coal or wood, releasing significant CO2 and contributing to deforestation and air pollution. Fly ash bricks use industrial waste, reducing landfill burden and conserving natural resources while producing less greenhouse gas emissions due to lower firing temperatures. Their sustainable manufacturing process supports eco-friendly construction by minimizing resource extraction and energy consumption compared to traditional red bricks.

Thermal Insulation Properties

Red bricks have moderate thermal insulation properties due to their dense clay composition, which retains heat but can lead to higher indoor temperatures in hot climates. Fly ash bricks offer superior thermal insulation by incorporating fly ash, which has a lower thermal conductivity, resulting in better energy efficiency and reduced cooling loads. Choosing fly ash bricks can enhance building sustainability by minimizing heat transfer and maintaining comfortable indoor temperatures.

Cost Analysis and Affordability

Red bricks typically cost more due to traditional manufacturing processes and higher raw material expenses, whereas fly ash bricks are more affordable because of their eco-friendly production using industrial waste. Fly ash bricks offer savings of up to 20-25% compared to red bricks, making them a cost-effective option for large-scale construction projects. Long-term affordability is enhanced with fly ash bricks due to their lower water absorption and better thermal insulation, reducing maintenance and energy costs.

Water Absorption and Efflorescence

Red bricks typically exhibit higher water absorption rates, ranging from 15% to 20%, which can lead to increased moisture retention and potential structural issues over time. Fly ash bricks have lower water absorption, generally below 12%, enhancing durability and reducing the risk of efflorescence, a common problem caused by salt deposits formed due to excess moisture. The lower porosity and improved manufacturing process of fly ash bricks significantly minimize efflorescence, making them a preferred choice for damp environments.

Suitability for Different Construction Types

Red bricks are highly suitable for load-bearing walls and traditional residential constructions due to their high compressive strength and durability. Fly ash bricks excel in non-load bearing walls, partition walls, and low-rise buildings because they offer superior thermal insulation and eco-friendliness while maintaining adequate strength. Selecting the appropriate brick type depends on structural requirements, environmental conditions, and specific project demands in construction.

Aesthetic Appeal and Design Flexibility

Red bricks offer a traditional, warm aesthetic with rich textures and natural color variations ideal for classic architectural designs. Fly ash bricks provide a smooth surface and uniform appearance, enabling sleek, modern designs with greater precision in shape and size. Both materials support diverse aesthetic choices, but fly ash bricks enhance design flexibility through customizable finishes and consistent dimensions.

Conclusion: Choosing the Right Brick for Your Project

Red bricks offer superior strength and durability, making them ideal for load-bearing structures and traditional construction projects. Fly ash bricks provide eco-friendly advantages with better thermal insulation and lighter weight, suitable for energy-efficient buildings and faster construction. Evaluating project requirements, environmental impact, and budget will guide the optimal choice between red brick and fly ash brick.

Red Brick vs Fly Ash Brick Infographic

productdif.com

productdif.com