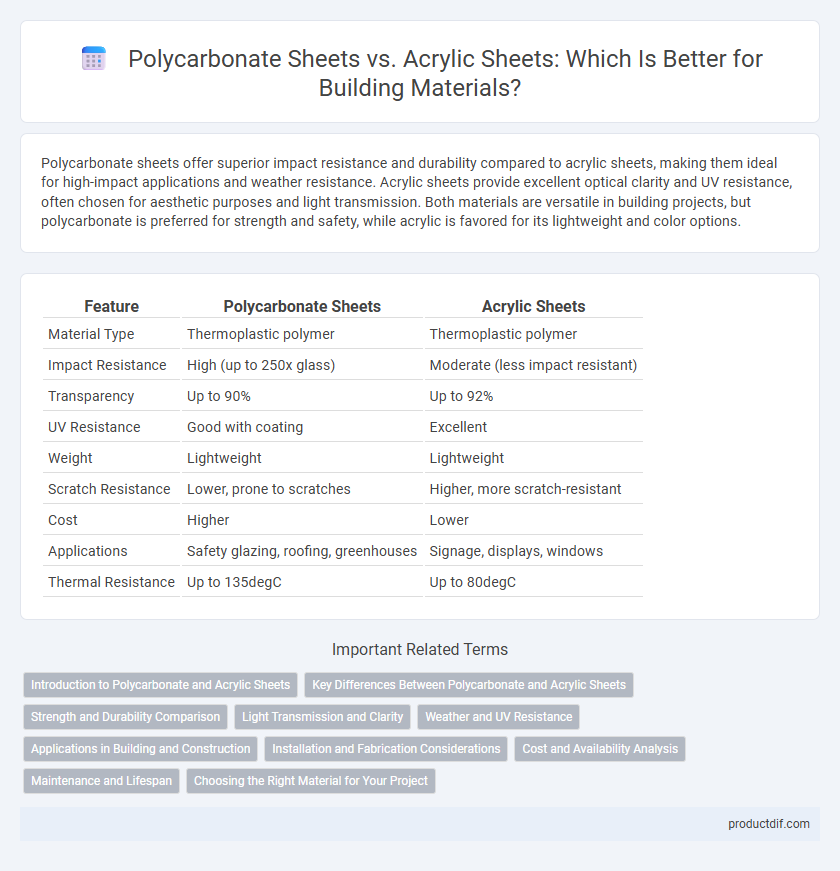

Polycarbonate sheets offer superior impact resistance and durability compared to acrylic sheets, making them ideal for high-impact applications and weather resistance. Acrylic sheets provide excellent optical clarity and UV resistance, often chosen for aesthetic purposes and light transmission. Both materials are versatile in building projects, but polycarbonate is preferred for strength and safety, while acrylic is favored for its lightweight and color options.

Table of Comparison

| Feature | Polycarbonate Sheets | Acrylic Sheets |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polymer |

| Impact Resistance | High (up to 250x glass) | Moderate (less impact resistant) |

| Transparency | Up to 90% | Up to 92% |

| UV Resistance | Good with coating | Excellent |

| Weight | Lightweight | Lightweight |

| Scratch Resistance | Lower, prone to scratches | Higher, more scratch-resistant |

| Cost | Higher | Lower |

| Applications | Safety glazing, roofing, greenhouses | Signage, displays, windows |

| Thermal Resistance | Up to 135degC | Up to 80degC |

Introduction to Polycarbonate and Acrylic Sheets

Polycarbonate sheets are durable, impact-resistant thermoplastic materials known for their high strength and transparency, commonly used in construction and glazing applications. Acrylic sheets, also referred to as plexiglass, offer excellent clarity and weather resistance with lighter weight but lower impact resistance compared to polycarbonate. Both materials provide versatile solutions for building projects requiring transparent or translucent panels with varying degrees of toughness and flexibility.

Key Differences Between Polycarbonate and Acrylic Sheets

Polycarbonate sheets offer superior impact resistance, being nearly 250 times stronger than glass, while acrylic sheets provide excellent clarity and UV resistance but are more prone to cracking under heavy impact. Polycarbonate is more flexible and heat resistant up to 270degC, making it suitable for applications requiring durability and thermal stability, whereas acrylic typically withstands temperatures up to 80-90degC. Cost-wise, acrylic sheets are more affordable but less durable, whereas polycarbonate sheets justify a higher investment with enhanced strength and longevity in demanding environments.

Strength and Durability Comparison

Polycarbonate sheets offer superior impact resistance, being up to 250 times stronger than glass and significantly more durable than acrylic sheets. Acrylic sheets, while more scratch-resistant, are prone to cracking under heavy stress or impact due to their lower tensile strength. The high durability and toughness of polycarbonate make it the preferred choice for applications requiring enhanced protection and long-term performance.

Light Transmission and Clarity

Polycarbonate sheets typically offer light transmission rates between 85% and 90%, making them slightly less clear than acrylic sheets, which boast transmission rates up to 92%. Acrylic sheets are known for their superior optical clarity and higher resistance to yellowing over time, maintaining transparency longer in outdoor applications. Polycarbonate, while slightly lower in clarity, provides greater impact resistance and durability, suitable for environments where strength and light transmission are both critical factors.

Weather and UV Resistance

Polycarbonate sheets offer superior weather and UV resistance compared to acrylic sheets, making them ideal for outdoor applications. Their enhanced UV-stabilized coatings prevent yellowing and deterioration under prolonged sun exposure, ensuring durability. Acrylic sheets, while resistant to UV rays, tend to degrade faster and are less impact-resistant in harsh weather conditions.

Applications in Building and Construction

Polycarbonate sheets offer superior impact resistance and UV protection, making them ideal for roofing, skylights, and safety glazing in building and construction. Acrylic sheets provide excellent clarity and weather resistance, commonly used for windows, signage, and decorative panels. Both materials serve distinct purposes, with polycarbonate favored for durability and acrylic for aesthetic appeal in architectural applications.

Installation and Fabrication Considerations

Polycarbonate sheets offer superior impact resistance and can be cold-formed without cracking, making them ideal for complex installations requiring flexibility. Acrylic sheets require precise cutting and heating for shaping, as they are more brittle and prone to cracking during fabrication. Both materials need specialized tools, but polycarbonate's higher thermal expansion must be accounted for during installation to avoid warping.

Cost and Availability Analysis

Polycarbonate sheets generally cost more than acrylic sheets due to their higher impact resistance and durability, making them ideal for demanding construction applications. Acrylic sheets offer a more budget-friendly option and are widely available in various thicknesses and finishes, suitable for decorative and light structural uses. Both materials are commonly stocked by major building suppliers, but acrylic's longer market presence often ensures quicker availability in standard sizes.

Maintenance and Lifespan

Polycarbonate sheets offer superior impact resistance and weather durability, requiring minimal maintenance compared to acrylic sheets prone to surface scratching and discoloration over time. Acrylic sheets may need regular cleaning with non-abrasive agents and occasional polishing to maintain clarity, while polycarbonate's UV-resistant coatings extend its lifespan up to 10-15 years in outdoor applications. Choosing polycarbonate ensures long-term cost efficiency due to its robustness and lower upkeep demands.

Choosing the Right Material for Your Project

Polycarbonate sheets offer superior impact resistance and UV protection, making them ideal for outdoor applications requiring durability and weather resistance. Acrylic sheets provide excellent clarity and are more scratch-resistant, suitable for projects where optical quality and aesthetics are priorities. Selecting between polycarbonate and acrylic depends on factors like environmental exposure, strength requirements, and budget constraints to ensure optimal performance and longevity.

Polycarbonate Sheets vs Acrylic Sheets Infographic

productdif.com

productdif.com