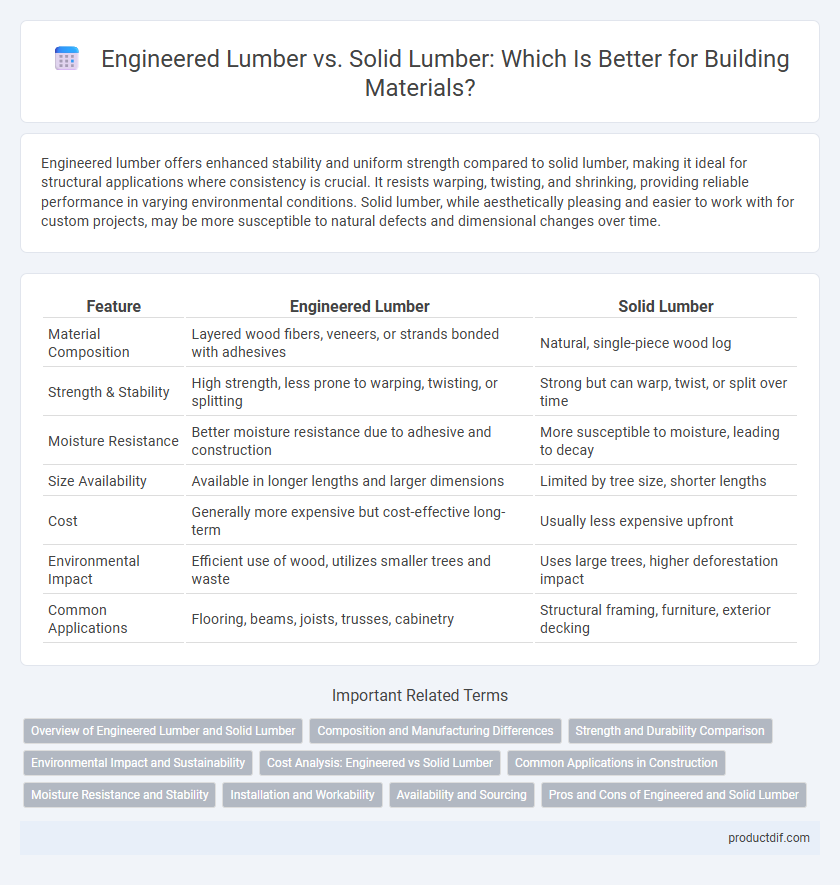

Engineered lumber offers enhanced stability and uniform strength compared to solid lumber, making it ideal for structural applications where consistency is crucial. It resists warping, twisting, and shrinking, providing reliable performance in varying environmental conditions. Solid lumber, while aesthetically pleasing and easier to work with for custom projects, may be more susceptible to natural defects and dimensional changes over time.

Table of Comparison

| Feature | Engineered Lumber | Solid Lumber |

|---|---|---|

| Material Composition | Layered wood fibers, veneers, or strands bonded with adhesives | Natural, single-piece wood log |

| Strength & Stability | High strength, less prone to warping, twisting, or splitting | Strong but can warp, twist, or split over time |

| Moisture Resistance | Better moisture resistance due to adhesive and construction | More susceptible to moisture, leading to decay |

| Size Availability | Available in longer lengths and larger dimensions | Limited by tree size, shorter lengths |

| Cost | Generally more expensive but cost-effective long-term | Usually less expensive upfront |

| Environmental Impact | Efficient use of wood, utilizes smaller trees and waste | Uses large trees, higher deforestation impact |

| Common Applications | Flooring, beams, joists, trusses, cabinetry | Structural framing, furniture, exterior decking |

Overview of Engineered Lumber and Solid Lumber

Engineered lumber consists of wood fibers, veneers, or strands combined with adhesives to create strong, dimensionally stable products like plywood, oriented strand board (OSB), and laminated veneer lumber (LVL). Solid lumber is cut directly from logs, retaining natural grain patterns and is commonly used for traditional framing, furniture, and finish carpentry. Engineered lumber offers enhanced uniformity, resistance to warping, and efficient material usage compared to solid lumber, which provides natural strength and aesthetics.

Composition and Manufacturing Differences

Engineered lumber is composed of multiple wood veneers, fibers, or strands bonded with adhesives under heat and pressure, creating a uniform and stable material. Solid lumber is cut directly from trees, consisting of natural, continuous grain wood with inherent variability and potential imperfections. The manufacturing of engineered lumber enhances strength and dimensional stability, while solid lumber retains natural grain patterns and requires careful grading for structural use.

Strength and Durability Comparison

Engineered lumber offers enhanced strength and uniform durability due to its layered construction, which reduces warping and splitting common in solid lumber. Solid lumber possesses natural grain variability that can impact its long-term stability under fluctuating environmental conditions. Structural applications benefit from engineered lumber's consistent performance and resistance to moisture-related deformation compared to traditional solid wood.

Environmental Impact and Sustainability

Engineered lumber offers significant environmental advantages over solid lumber by maximizing wood utilization and reducing waste through its layered construction from smaller, fast-growing trees. Its production process consumes less energy and contributes to lower greenhouse gas emissions compared to harvesting large, old-growth trees for solid lumber. Sustainable forestry practices combined with engineered lumber's ability to extend the life cycle of wood resources make it a more eco-friendly choice for environmentally conscious construction projects.

Cost Analysis: Engineered vs Solid Lumber

Engineered lumber typically offers a lower cost per linear foot compared to solid lumber, making it a budget-friendly choice for large-scale building projects. The manufacturing process of engineered lumber utilizes wood fibers and adhesives, which reduces waste and allows for the use of smaller or fast-growing trees, further driving down material expenses. While solid lumber can have higher upfront costs due to its natural grain quality and milling labor, engineered lumber provides more consistent pricing and enhanced material stability, resulting in potential long-term savings on maintenance and replacement.

Common Applications in Construction

Engineered lumber, such as LVL and I-joists, is commonly used in floor joists, roof rafters, and long-span beams due to its superior strength and dimensional stability. Solid lumber remains popular for framing walls, posts, and general-purpose studs because of its natural durability and ease of handling. Both materials serve critical roles, with engineered lumber favored in applications requiring uniformity and load-bearing capacity, while solid lumber is preferred for traditional structural elements.

Moisture Resistance and Stability

Engineered lumber offers superior moisture resistance compared to solid lumber due to its layered composition and use of adhesives that reduce water absorption and swelling. Its dimensional stability prevents warping, twisting, and shrinking commonly observed in solid lumber when exposed to fluctuating humidity levels. These properties make engineered lumber an ideal choice for environments prone to moisture and temperature changes.

Installation and Workability

Engineered lumber offers consistent dimensions and enhanced stability, simplifying installation by reducing the need for on-site adjustments compared to solid lumber. Its lighter weight and uniformity improve workability, allowing faster cutting and fastening, which minimizes labor time and errors. Solid lumber requires more effort to handle due to natural variations and higher susceptibility to warping, making installation more labor-intensive and less predictable.

Availability and Sourcing

Engineered lumber offers greater availability due to its production from layered wood fibers and adhesives, allowing consistent supply regardless of natural tree size or quality. Solid lumber relies on harvesting large, mature trees, making its sourcing dependent on regional forestry conditions and regulations, which can limit availability. Sustainable engineered products often utilize fast-growing species and reclaimed wood, enhancing supply chain efficiency compared to traditional solid wood lumber.

Pros and Cons of Engineered and Solid Lumber

Engineered lumber offers superior dimensional stability and resistance to warping, making it ideal for large spans and complex designs, while solid lumber provides natural strength, aesthetic appeal, and easier on-site modifications. Engineered lumber may have limitations in load-bearing capacity compared to some solid species and can be sensitive to moisture damage if not properly sealed. Solid lumber is prone to shrinkage and warping but is more readily available in traditional sizes and finishes, often preferred for visible structural elements.

Engineered Lumber vs Solid Lumber Infographic

productdif.com

productdif.com