Galvanized fasteners offer corrosion resistance through a zinc coating, making them ideal for outdoor use where exposure to moisture is a concern, while stainless steel fasteners provide superior durability and resistance to rust without additional coatings. Stainless steel fasteners excel in environments with high humidity or salt exposure, such as coastal areas, due to their chromium content that forms a protective layer. Choosing between galvanized and stainless steel fasteners depends on budget considerations and the specific environmental conditions of the construction project.

Table of Comparison

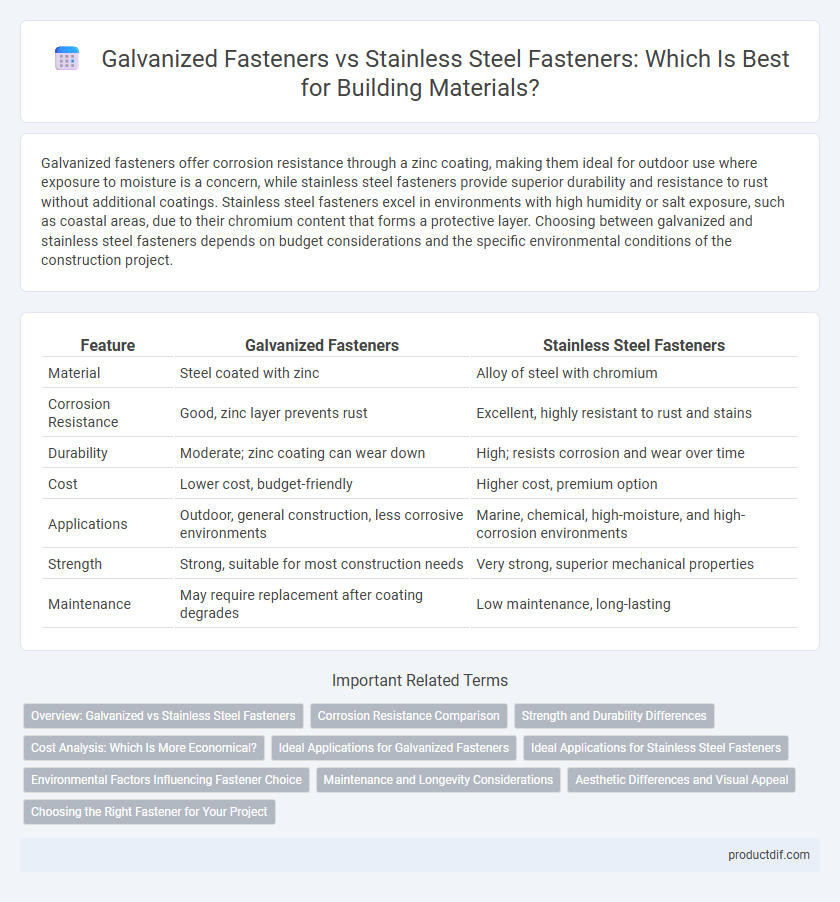

| Feature | Galvanized Fasteners | Stainless Steel Fasteners |

|---|---|---|

| Material | Steel coated with zinc | Alloy of steel with chromium |

| Corrosion Resistance | Good, zinc layer prevents rust | Excellent, highly resistant to rust and stains |

| Durability | Moderate; zinc coating can wear down | High; resists corrosion and wear over time |

| Cost | Lower cost, budget-friendly | Higher cost, premium option |

| Applications | Outdoor, general construction, less corrosive environments | Marine, chemical, high-moisture, and high-corrosion environments |

| Strength | Strong, suitable for most construction needs | Very strong, superior mechanical properties |

| Maintenance | May require replacement after coating degrades | Low maintenance, long-lasting |

Overview: Galvanized vs Stainless Steel Fasteners

Galvanized fasteners are coated with a layer of zinc to provide corrosion resistance, making them suitable for outdoor and wet environments while being cost-effective. Stainless steel fasteners contain chromium, offering superior durability and resistance to rust, ideal for high-moisture or acidic conditions. Choosing between galvanized and stainless steel fasteners depends on factors like environmental exposure, budget, and required longevity.

Corrosion Resistance Comparison

Galvanized fasteners feature a protective zinc coating that provides effective corrosion resistance in mildly corrosive environments, such as indoor or dry outdoor applications. Stainless steel fasteners offer superior corrosion resistance due to their chromium content, which forms a passive oxide layer, making them ideal for highly corrosive or marine environments. Choosing stainless steel fasteners ensures long-term durability and resistance to rust, especially in conditions with frequent moisture or chemical exposure.

Strength and Durability Differences

Galvanized fasteners feature a zinc coating that offers strong corrosion resistance but may weaken over time in harsh environments, while stainless steel fasteners provide superior strength and durability due to their alloy composition, resisting rust and maintaining integrity under extreme conditions. The tensile strength of stainless steel fasteners typically ranges from 70,000 to 120,000 psi, surpassing most galvanized fasteners, which generally exhibit lower mechanical strength. These qualities make stainless steel fasteners ideal for long-term structural applications where exposure to moisture and chemicals is significant.

Cost Analysis: Which Is More Economical?

Galvanized fasteners typically offer a lower upfront cost compared to stainless steel fasteners, making them a more economical choice for large-scale construction projects with budget constraints. While stainless steel fasteners have higher initial prices, their superior corrosion resistance and longer lifespan reduce maintenance and replacement costs over time, potentially providing better long-term value. Evaluating total cost of ownership, including durability and environmental exposure, is essential for selecting the most cost-effective fastening solution in building material applications.

Ideal Applications for Galvanized Fasteners

Galvanized fasteners are ideal for outdoor construction projects where moderate corrosion resistance is required, such as fencing, decking, and roofing applications. Their zinc coating provides robust protection against rust in environments exposed to moisture but not in highly corrosive or marine conditions. These fasteners are cost-effective solutions for structural wood framing, siding, and general exterior fastening needs.

Ideal Applications for Stainless Steel Fasteners

Stainless steel fasteners excel in environments exposed to moisture, chemicals, and extreme temperatures, making them ideal for marine, automotive, and construction projects requiring superior corrosion resistance. Their non-corrosive properties ensure long-term durability in structural components, outdoor installations, and architectural applications. High tensile strength and resistance to tarnishing also make stainless steel fasteners suitable for food processing and pharmaceutical equipment assembly.

Environmental Factors Influencing Fastener Choice

Environmental factors such as humidity, salt exposure, and temperature fluctuations significantly impact the performance of galvanized fasteners versus stainless steel fasteners. Galvanized fasteners provide effective corrosion resistance in moderately corrosive environments, making them suitable for indoor or low-moisture applications. Stainless steel fasteners excel in highly corrosive conditions, including marine or chemical exposure, due to their superior resistance to rust and oxidation, ensuring long-term durability.

Maintenance and Longevity Considerations

Galvanized fasteners require periodic inspection for coating wear and potential rust spots, especially in high-moisture environments, to maintain structural integrity. Stainless steel fasteners offer superior corrosion resistance with minimal maintenance, making them ideal for harsh weather and chemical exposure. Longevity of stainless steel fasteners significantly outperforms galvanized alternatives, reducing replacement frequency and lifecycle costs in building projects.

Aesthetic Differences and Visual Appeal

Galvanized fasteners feature a matte gray finish with a slightly rough texture, which offers a utilitarian appearance suitable for industrial and rustic designs. Stainless steel fasteners present a smooth, shiny surface with a polished silver look that enhances modern and high-end architectural aesthetics. The choice between these materials significantly impacts the visual appeal of building projects, with stainless steel providing a cleaner, more refined finish compared to the rugged, weathered charm of galvanized fasteners.

Choosing the Right Fastener for Your Project

Galvanized fasteners offer superior corrosion resistance for outdoor projects due to their zinc coating, making them ideal for wood framing and decking in humid or wet environments. Stainless steel fasteners excel in durability and rust resistance, suitable for marine, chemical, or high-salinity applications where long-term performance is critical. Selecting the right fastener depends on project exposure, structural requirements, and budget, balancing corrosion protection with mechanical strength to ensure longevity.

galvanized fasteners vs stainless steel fasteners Infographic

productdif.com

productdif.com