Concrete blocks offer superior strength and durability for heavy-load structures, making them ideal for foundations and retaining walls. Aerated blocks provide excellent thermal insulation and are lightweight, which reduces construction time and overall building weight. Choosing between the two depends on the specific project requirements, balancing structural needs and energy efficiency.

Table of Comparison

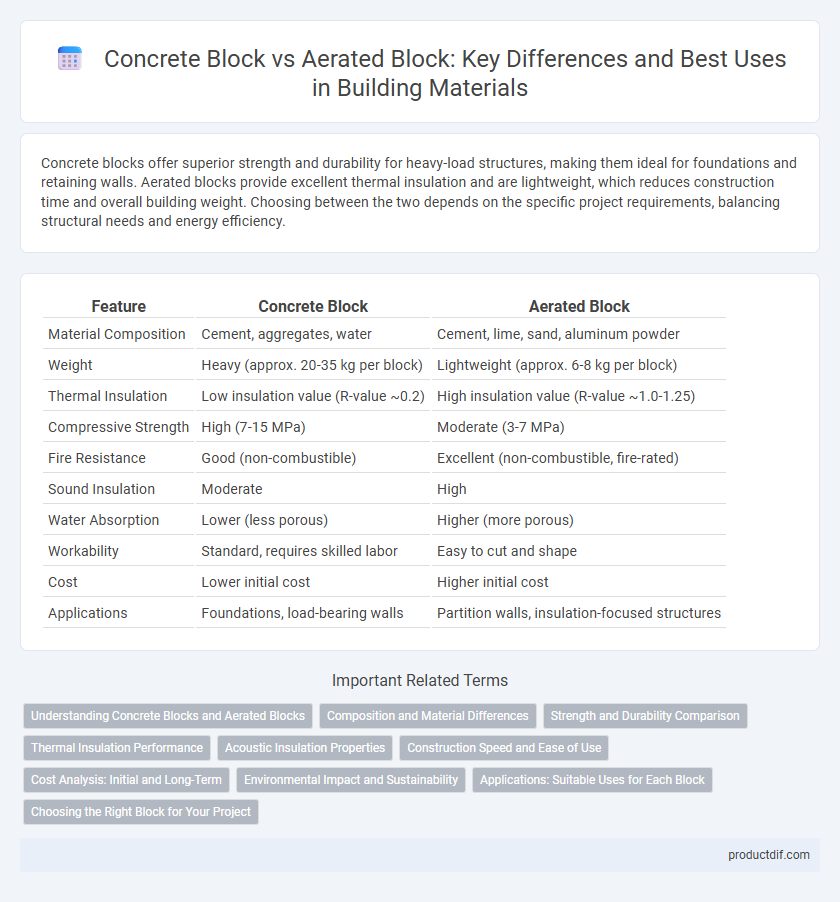

| Feature | Concrete Block | Aerated Block |

|---|---|---|

| Material Composition | Cement, aggregates, water | Cement, lime, sand, aluminum powder |

| Weight | Heavy (approx. 20-35 kg per block) | Lightweight (approx. 6-8 kg per block) |

| Thermal Insulation | Low insulation value (R-value ~0.2) | High insulation value (R-value ~1.0-1.25) |

| Compressive Strength | High (7-15 MPa) | Moderate (3-7 MPa) |

| Fire Resistance | Good (non-combustible) | Excellent (non-combustible, fire-rated) |

| Sound Insulation | Moderate | High |

| Water Absorption | Lower (less porous) | Higher (more porous) |

| Workability | Standard, requires skilled labor | Easy to cut and shape |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Foundations, load-bearing walls | Partition walls, insulation-focused structures |

Understanding Concrete Blocks and Aerated Blocks

Concrete blocks consist of cement, water, and aggregates, providing high compressive strength and durability ideal for load-bearing walls and foundations. Aerated blocks, made from cement, lime, sand, water, and an aerating agent, offer lightweight properties and excellent thermal insulation, reducing construction time and energy costs. Comparing these materials reveals concrete blocks excel in strength, while aerated blocks enhance building efficiency through superior insulation and ease of handling.

Composition and Material Differences

Concrete blocks are composed primarily of cement, water, and aggregates such as sand or gravel, providing high density and compressive strength ideal for load-bearing structures. Aerated blocks, also known as AAC (autoclaved aerated concrete) blocks, contain cement, lime, sand, water, and an expanding agent like aluminum powder, which creates a lightweight and porous material with superior thermal insulation. The material differences result in concrete blocks being heavier and more durable, while aerated blocks offer improved energy efficiency and easier handling due to their reduced weight and porous composition.

Strength and Durability Comparison

Concrete blocks exhibit higher compressive strength, typically ranging from 7 to 15 MPa, making them suitable for load-bearing walls and heavy structural applications. Aerated blocks, with strengths around 3 to 7 MPa, offer superior thermal insulation but lower density and durability compared to concrete blocks. Concrete blocks possess greater resistance to weathering and moisture, enhancing long-term durability in harsh environments.

Thermal Insulation Performance

Concrete blocks have a thermal conductivity value ranging between 1.1 to 1.7 W/mK, resulting in moderate insulation properties suitable for standard construction. Aerated blocks, specifically autoclaved aerated concrete (AAC), offer superior thermal insulation with conductivity values as low as 0.1 to 0.3 W/mK, significantly reducing heat transfer and enhancing energy efficiency in buildings. This improved insulation contributes to lower heating and cooling costs, making aerated blocks a preferred choice for energy-conscious construction projects.

Acoustic Insulation Properties

Concrete blocks exhibit superior acoustic insulation due to their higher density and mass, effectively dampening sound transmission in building structures. Aerated blocks, while lighter and thermally efficient, offer less soundproofing as their porous composition allows more noise penetration. For projects demanding enhanced noise control, concrete blocks provide a more robust solution in acoustic performance.

Construction Speed and Ease of Use

Concrete blocks offer robust durability but require more time and labor for installation due to their weight and mortar application. Aerated blocks are significantly lighter and larger, enabling faster construction and easier handling, which reduces overall labor costs and project timelines. Their uniform size and smooth surface allow for quicker finishing work, enhancing construction efficiency.

Cost Analysis: Initial and Long-Term

Concrete blocks generally have a lower initial cost due to widespread availability and simpler manufacturing processes, making them cost-effective for large-scale construction projects. Aerated blocks, while more expensive upfront because of specialized production and materials, offer long-term savings through superior thermal insulation and reduced energy consumption for heating and cooling. Over the lifespan of a building, the energy efficiency and lightweight nature of aerated blocks can offset initial expenses, resulting in overall cost benefits compared to traditional concrete blocks.

Environmental Impact and Sustainability

Concrete blocks have a higher carbon footprint due to cement production, while aerated blocks offer enhanced sustainability by incorporating recycled materials and requiring less energy in manufacturing. Aerated blocks provide better insulation properties, reducing energy consumption for heating and cooling in buildings, which significantly lowers long-term environmental impact. Lifecycle assessments reveal that aerated blocks contribute to lower greenhouse gas emissions and promote resource efficiency in sustainable construction projects.

Applications: Suitable Uses for Each Block

Concrete blocks are ideal for structural applications such as load-bearing walls, foundations, and retaining walls due to their high compressive strength and durability. Aerated blocks are preferred for non-load-bearing walls, partition walls, and insulation layers because of their lightweight, thermal insulation, and soundproofing properties. Selecting the appropriate block depends on the specific construction requirements, balancing strength and energy efficiency in building projects.

Choosing the Right Block for Your Project

Concrete blocks provide superior strength and durability ideal for load-bearing walls and foundations, making them suitable for heavy structural applications. Aerated blocks offer excellent thermal insulation and lightweight properties, reducing construction time and improving energy efficiency in residential buildings. Selecting the right block depends on project requirements such as load capacity, climate conditions, and budget constraints to ensure optimal performance and cost-effectiveness.

Concrete Block vs Aerated Block Infographic

productdif.com

productdif.com