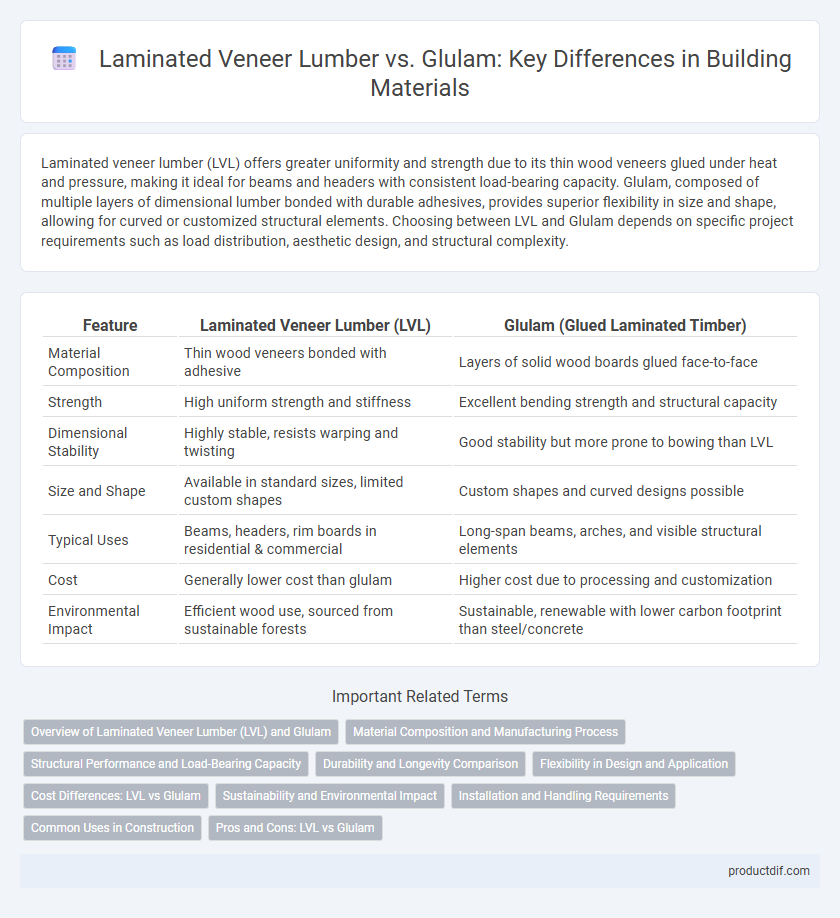

Laminated veneer lumber (LVL) offers greater uniformity and strength due to its thin wood veneers glued under heat and pressure, making it ideal for beams and headers with consistent load-bearing capacity. Glulam, composed of multiple layers of dimensional lumber bonded with durable adhesives, provides superior flexibility in size and shape, allowing for curved or customized structural elements. Choosing between LVL and Glulam depends on specific project requirements such as load distribution, aesthetic design, and structural complexity.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Glulam (Glued Laminated Timber) |

|---|---|---|

| Material Composition | Thin wood veneers bonded with adhesive | Layers of solid wood boards glued face-to-face |

| Strength | High uniform strength and stiffness | Excellent bending strength and structural capacity |

| Dimensional Stability | Highly stable, resists warping and twisting | Good stability but more prone to bowing than LVL |

| Size and Shape | Available in standard sizes, limited custom shapes | Custom shapes and curved designs possible |

| Typical Uses | Beams, headers, rim boards in residential & commercial | Long-span beams, arches, and visible structural elements |

| Cost | Generally lower cost than glulam | Higher cost due to processing and customization |

| Environmental Impact | Efficient wood use, sourced from sustainable forests | Sustainable, renewable with lower carbon footprint than steel/concrete |

Overview of Laminated Veneer Lumber (LVL) and Glulam

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin wood veneers together under heat and pressure, offering high strength and uniformity for structural applications like beams, headers, and joists. Glulam, or glued laminated timber, consists of several layers of dimensional lumber bonded with durable adhesives, providing large structural elements that are both strong and aesthetically versatile for use in beams, columns, and arches. Both LVL and Glulam enhance wood's natural properties engineered for high load-bearing capacity and dimensional stability in modern construction.

Material Composition and Manufacturing Process

Laminated veneer lumber (LVL) is composed of thin wood veneers bonded together with adhesive under heat and pressure, offering uniform strength and dimensional stability. Glulam consists of multiple layers of solid wood laminations glued with durable adhesives, typically displaying natural grain patterns that contribute to its aesthetic appeal. The manufacturing process of LVL involves peeling logs into veneers, while glulam production uses sawn lumber, both engineered to enhance structural performance in construction.

Structural Performance and Load-Bearing Capacity

Laminated veneer lumber (LVL) offers high structural performance with consistent strength and stiffness due to its thin wood veneers bonded under pressure, making it ideal for load-bearing applications requiring uniformity. Glulam, composed of multiple layers of dimensional lumber glued together, provides exceptional load-bearing capacity with the ability to span large distances and resist bending forces effectively. Both materials exhibit superior strength-to-weight ratios compared to traditional solid wood, but LVL excels in precision and dimensional stability, while Glulam allows for greater architectural flexibility in structural designs.

Durability and Longevity Comparison

Laminated veneer lumber (LVL) and glulam both offer high durability, but LVL is engineered with thin wood veneers bonded under heat and pressure, resulting in exceptional strength and uniformity that resists warping and splitting over time. Glulam, made from multiple layers of solid wood laminations glued together, provides excellent structural integrity and natural resistance to moisture when treated properly, contributing to its long lifespan. In terms of longevity, LVL demonstrates superior dimensional stability and resistance to environmental factors, making it a preferred choice for applications requiring consistent performance under heavy loads and variable conditions.

Flexibility in Design and Application

Laminated veneer lumber (LVL) offers superior uniformity and dimensional stability, making it ideal for precise, repetitive structural elements in residential and commercial projects. Glulam beams provide greater flexibility in design, allowing for curved and custom-shaped applications often used in architecturally expressive structures. Both materials excel in strength and durability, but glulam's ability to accommodate complex shapes gives it an advantage in innovative construction designs.

Cost Differences: LVL vs Glulam

Laminated veneer lumber (LVL) typically costs less than glulam due to its streamlined manufacturing process using thin wood veneers bonded under heat and pressure. Glulam involves the assembly of multiple dimensional lumber layers, which increases labor and material expenses, contributing to a higher price point. Cost differences between LVL and glulam also depend on project scale, load requirements, and availability of raw materials in regional markets.

Sustainability and Environmental Impact

Laminated veneer lumber (LVL) and glulam both offer sustainable alternatives to traditional solid wood by utilizing fast-growing timber and maximizing wood yield through engineered layering techniques. LVL typically uses thin wood veneers bonded with adhesives, resulting in high strength-to-weight ratios and reduced waste, while glulam combines larger timber laminations, often showcasing better recyclability and easier end-of-life disassembly. Both materials contribute to carbon sequestration and reduced deforestation, but LVL's manufacturing process can have higher adhesive emissions, whereas glulam's use of larger laminates may lower embodied energy, influencing their overall environmental impact profiles.

Installation and Handling Requirements

Laminated veneer lumber (LVL) requires careful handling due to its thinner, layered veneers, which are more susceptible to delamination if exposed to excessive moisture or impact during installation. Glulam beams, composed of thicker glued laminations, offer greater dimensional stability and are easier to handle with standard lifting equipment, reducing on-site labor intensity. Both materials demand precise alignment and fastening methods, but glulam's robust structure typically allows for more flexibility in installation tolerances.

Common Uses in Construction

Laminated veneer lumber (LVL) is commonly used for structural beams, headers, rim boards, and edge-forming material in walls due to its high strength and dimensional stability. Glulam is frequently utilized in long-span beams, arches, and columns for both residential and commercial buildings, offering flexibility in architectural design and aesthetic appeal. Both materials provide engineered wood solutions that enhance load-bearing capacity and reduce material waste in construction projects.

Pros and Cons: LVL vs Glulam

Laminated Veneer Lumber (LVL) offers superior strength-to-weight ratio and consistent quality due to its thin wood veneers bonded under heat and pressure, making it ideal for long-span applications and precise structural components. Glulam (Glued Laminated Timber) provides greater design flexibility and aesthetic appeal with thicker layers of timber, enabling curved and large-scale beams, but it may have more variability in strength and require more labor-intensive fabrication. LVL typically excels in uniform load-bearing capacity, while Glulam supports more architectural complexity and visual warmth, influencing the choice based on project requirements and structural performance.

Laminated veneer lumber vs Glulam Infographic

productdif.com

productdif.com