AAC (Autoclaved Aerated Concrete) offers superior thermal insulation and lighter weight compared to CLC (Cellular Lightweight Concrete), making it ideal for energy-efficient construction. CLC provides better load-bearing capacity and is more cost-effective for larger structural elements, ensuring durability in heavy-duty applications. Both materials enhance sustainability, with AAC excelling in reducing environmental impact through less raw material usage and CLC focusing on waste utilization and recycling.

Table of Comparison

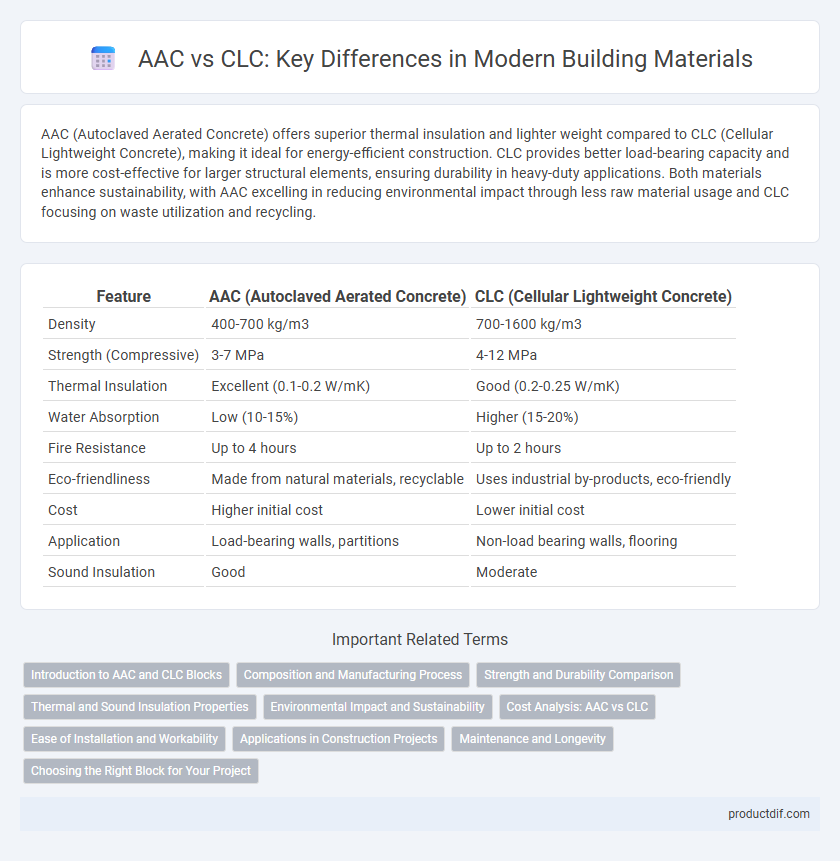

| Feature | AAC (Autoclaved Aerated Concrete) | CLC (Cellular Lightweight Concrete) |

|---|---|---|

| Density | 400-700 kg/m3 | 700-1600 kg/m3 |

| Strength (Compressive) | 3-7 MPa | 4-12 MPa |

| Thermal Insulation | Excellent (0.1-0.2 W/mK) | Good (0.2-0.25 W/mK) |

| Water Absorption | Low (10-15%) | Higher (15-20%) |

| Fire Resistance | Up to 4 hours | Up to 2 hours |

| Eco-friendliness | Made from natural materials, recyclable | Uses industrial by-products, eco-friendly |

| Cost | Higher initial cost | Lower initial cost |

| Application | Load-bearing walls, partitions | Non-load bearing walls, flooring |

| Sound Insulation | Good | Moderate |

Introduction to AAC and CLC Blocks

AAC blocks, or Autoclaved Aerated Concrete, are lightweight, precast building materials known for their excellent thermal insulation, fire resistance, and ease of installation due to their porous structure. CLC blocks, or Cellular Lightweight Concrete blocks, are made using a slurry of cement, water, and foam, offering high strength-to-weight ratio and enhanced sound insulation properties. Both AAC and CLC blocks contribute to sustainable construction by reducing overall building weight and improving energy efficiency.

Composition and Manufacturing Process

Autoclaved Aerated Concrete (AAC) consists primarily of cement, lime, silica sand, water, and an expanding agent such as aluminum powder, which induces a reaction forming tiny air pockets. Cellular Lightweight Concrete (CLC) uses cement, water, and a foaming agent to create air bubbles that solidify in the mix, resulting in a lightweight, porous structure. AAC undergoes high-pressure steam curing in autoclaves, enhancing strength and durability, whereas CLC hardens through air curing without autoclaving, making its production less energy-intensive.

Strength and Durability Comparison

Aerated Autoclaved Concrete (AAC) exhibits lower compressive strength, typically ranging from 2 to 8 MPa, compared to Cellular Lightweight Concrete (CLC), which can achieve strengths up to 15 MPa depending on density and mix design. AAC offers excellent durability due to its high resistance to fire, moisture, and pests, but CLC provides superior structural strength and better resistance to impact and abrasion. The choice between AAC and CLC should consider specific project requirements for load-bearing capacity and long-term performance in various environmental conditions.

Thermal and Sound Insulation Properties

AAC (Autoclaved Aerated Concrete) offers superior thermal insulation due to its porous cellular structure, resulting in a lower thermal conductivity typically around 0.12-0.16 W/m*K, compared to CLC (Cellular Lightweight Concrete) which generally ranges from 0.2-0.3 W/m*K. AAC's lightweight composition also enhances sound insulation by effectively dampening sound waves, while CLC provides moderate soundproofing but often requires additional treatment for high-performance acoustic needs. The enhanced thermal and sound insulation properties of AAC make it a preferred choice for energy-efficient and noise-sensitive construction projects.

Environmental Impact and Sustainability

Autoclaved Aerated Concrete (AAC) exhibits superior environmental benefits compared to Cellular Lightweight Concrete (CLC) due to its lower embodied energy and reduced carbon footprint during manufacturing. AAC's use of non-toxic raw materials and recyclability enhances sustainability by minimizing waste and promoting energy efficiency in construction. In contrast, CLC often involves higher cement content, leading to increased CO2 emissions and less favorable ecological impacts over its lifecycle.

Cost Analysis: AAC vs CLC

Autoclaved Aerated Concrete (AAC) generally presents higher initial material costs compared to Cellular Lightweight Concrete (CLC), but AAC offers superior thermal insulation and faster installation, reducing long-term operational expenses. CLC is more cost-effective in raw material consumption and labor due to simpler production techniques and local material availability, making it ideal for budget-sensitive projects. Evaluating life-cycle costs, AAC's energy savings often outweigh its upfront price difference, while CLC remains competitive in lightweight structural applications with lower short-term capital investment.

Ease of Installation and Workability

AAC (Autoclaved Aerated Concrete) offers superior ease of installation compared to CLC (Cellular Light-weight Concrete) due to its lightweight properties, precise block sizes, and uniform texture, which reduce labor time and effort. Its high workability allows for easy cutting, shaping, and drilling using standard tools, enhancing on-site adaptability. CLC, while lightweight, requires additional curing and handling care, making AAC the preferred choice for faster and more efficient construction workflows.

Applications in Construction Projects

Autoclaved Aerated Concrete (AAC) offers superior thermal insulation and lightweight properties, making it ideal for residential buildings, high-rise structures, and energy-efficient construction projects. Cellular Lightweight Concrete (CLC) is preferred for non-load-bearing walls, flooring, and void filling due to its excellent sound insulation and lightweight characteristics. Both materials enhance sustainability and reduce structural load but are selected based on specific project requirements and performance criteria.

Maintenance and Longevity

AAC (Autoclaved Aerated Concrete) offers superior longevity due to its lightweight and porous structure, which reduces cracking and structural wear over time. CLC (Cellular Lightweight Concrete) requires more frequent maintenance as its denser composition is prone to moisture absorption, leading to potential deterioration and surface damage. Proper sealing and regular inspections enhance the durability of both AAC and CLC, but AAC generally demands less upkeep and ensures longer-lasting performance in building construction.

Choosing the Right Block for Your Project

AAC blocks offer superior thermal insulation and lightweight properties, reducing structural load and energy costs, making them ideal for multi-story buildings and green construction projects. CLC blocks provide excellent compressive strength and sound insulation, suitable for load-bearing walls and budget-conscious projects where durability is essential. Evaluating project requirements like insulation, weight, cost, and structural load helps determine the optimal choice between AAC and CLC blocks.

AAC vs CLC Infographic

productdif.com

productdif.com