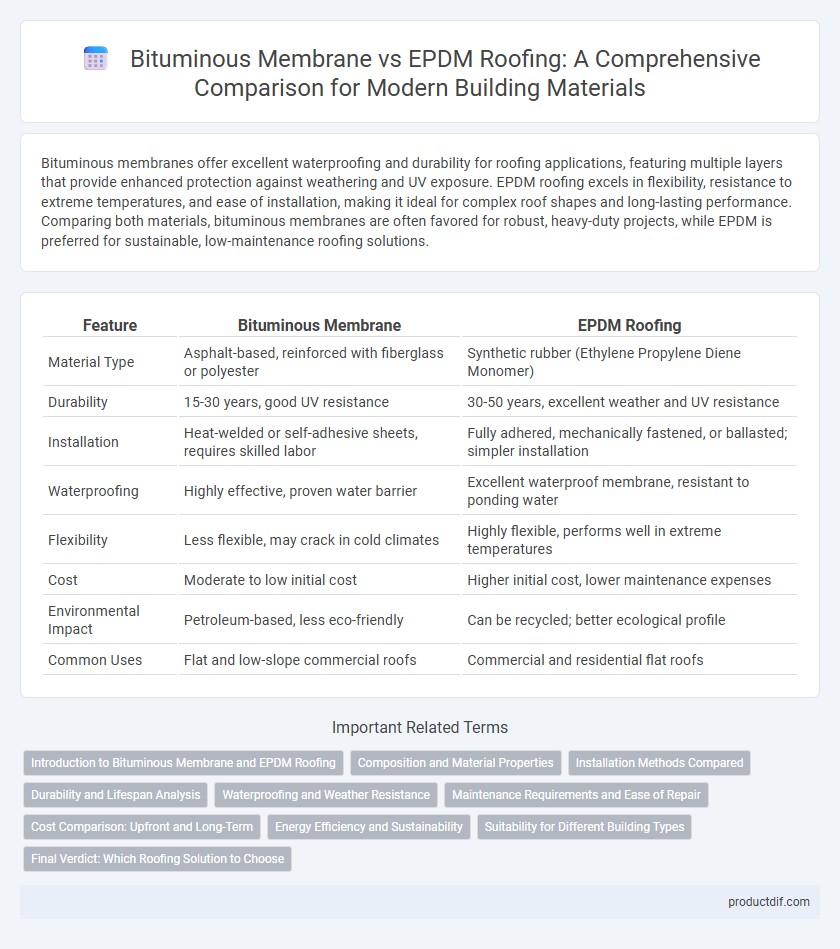

Bituminous membranes offer excellent waterproofing and durability for roofing applications, featuring multiple layers that provide enhanced protection against weathering and UV exposure. EPDM roofing excels in flexibility, resistance to extreme temperatures, and ease of installation, making it ideal for complex roof shapes and long-lasting performance. Comparing both materials, bituminous membranes are often favored for robust, heavy-duty projects, while EPDM is preferred for sustainable, low-maintenance roofing solutions.

Table of Comparison

| Feature | Bituminous Membrane | EPDM Roofing |

|---|---|---|

| Material Type | Asphalt-based, reinforced with fiberglass or polyester | Synthetic rubber (Ethylene Propylene Diene Monomer) |

| Durability | 15-30 years, good UV resistance | 30-50 years, excellent weather and UV resistance |

| Installation | Heat-welded or self-adhesive sheets, requires skilled labor | Fully adhered, mechanically fastened, or ballasted; simpler installation |

| Waterproofing | Highly effective, proven water barrier | Excellent waterproof membrane, resistant to ponding water |

| Flexibility | Less flexible, may crack in cold climates | Highly flexible, performs well in extreme temperatures |

| Cost | Moderate to low initial cost | Higher initial cost, lower maintenance expenses |

| Environmental Impact | Petroleum-based, less eco-friendly | Can be recycled; better ecological profile |

| Common Uses | Flat and low-slope commercial roofs | Commercial and residential flat roofs |

Introduction to Bituminous Membrane and EPDM Roofing

Bituminous membrane roofing consists of asphalt-based materials reinforced with polyester or fiberglass for enhanced durability and waterproofing properties, often used in low-slope roofs due to its excellent resistance to water and UV radiation. EPDM roofing, made from ethylene propylene diene monomer rubber, offers superior flexibility, longevity, and resistance to extreme weather conditions, making it a popular choice for commercial and residential flat roofs. Both materials provide effective waterproofing solutions, but EPDM typically offers easier installation and greater elasticity compared to the rigid structure of bituminous membranes.

Composition and Material Properties

Bituminous membranes are composed of asphalt-based materials reinforced with polyester or fiberglass mats, offering strong waterproofing and UV resistance, while EPDM roofing consists of synthetic rubber polymers known for exceptional flexibility and weather durability. Bituminous membranes provide high resistance to punctures and are self-adhesive or torch-applied for secure installation, whereas EPDM membranes excel in elasticity and ozone resistance, maintaining performance in extreme temperatures. Both materials deliver effective roofing solutions, but EPDM's rubber composition enables superior elasticity, and bituminous membranes offer enhanced robustness from their asphalt reinforcement.

Installation Methods Compared

Bituminous membranes require heating with a torch or hot asphalt for proper adhesion, making their installation labor-intensive and suited for experienced contractors. EPDM roofing typically uses adhesive or mechanical fasteners, allowing for quicker, safer installation without open flames. Both methods demand precise surface preparation but differ significantly in complexity and safety considerations during application.

Durability and Lifespan Analysis

Bituminous membranes typically offer a lifespan of 15 to 30 years depending on installation quality and environmental conditions, with strong resistance to punctures and UV radiation. EPDM roofing exhibits superior durability, often lasting 30 to 50 years, excelling in elasticity and resistance to extreme weather and ozone exposure. Both materials provide robust waterproofing solutions, but EPDM's extended lifespan and flexibility generally result in lower long-term maintenance costs.

Waterproofing and Weather Resistance

Bituminous membranes offer excellent waterproofing through their multi-layer asphalt composition, providing robust resistance against water infiltration and UV radiation. EPDM roofing excels in weather resistance due to its synthetic rubber formulation, which tolerates extreme temperatures, ozone, and UV exposure without cracking or shrinking. Both materials ensure durable waterproofing but EPDM typically provides superior flexibility and longevity in harsh climatic conditions.

Maintenance Requirements and Ease of Repair

Bituminous membranes require regular inspection for cracks and blisters to prevent water infiltration, with repairs typically involving torch-applied or cold adhesive patches that can be labor-intensive. EPDM roofing demands minimal maintenance due to its UV resistance and flexibility, and repairs are efficient with peel-and-stick patches or liquid adhesives that cure quickly. The durability and simpler repair process of EPDM often reduce long-term upkeep costs compared to bituminous membranes.

Cost Comparison: Upfront and Long-Term

Bituminous membranes typically offer a lower initial cost compared to EPDM roofing, making them an attractive option for budget-conscious projects. However, EPDM roofs provide greater durability and require less maintenance over time, resulting in lower long-term expenses. Considering lifecycle cost analysis, EPDM often proves more cost-effective due to its extended lifespan and resistance to environmental damage.

Energy Efficiency and Sustainability

Bituminous membranes offer strong waterproofing and durability but typically have lower solar reflectance compared to EPDM roofing, impacting energy efficiency in hot climates. EPDM roofing excels in sustainability by being highly recyclable and providing superior insulation, which reduces heating and cooling costs. Choosing EPDM can lead to significant reductions in building energy consumption and environmental footprint over the roof's lifespan.

Suitability for Different Building Types

Bituminous membranes offer excellent waterproofing for residential and low-slope commercial buildings due to their durability and ease of installation. EPDM roofing is highly suitable for large commercial and industrial buildings with flat or low-slope roofs, providing superior resistance to UV radiation and extreme weather conditions. Each material's flexibility and lifecycle cost influence its selection based on the building type's exposure and structural requirements.

Final Verdict: Which Roofing Solution to Choose

Bituminous membrane roofing offers proven durability and excellent waterproofing properties, making it ideal for low-slope roofs requiring a cost-effective solution. EPDM roofing provides superior flexibility, UV resistance, and easier installation with fewer seams, enhancing longevity in varied climates. Choosing between the two depends on building specifications, budget constraints, and desired lifespan, with EPDM favored for long-term performance and bituminous membranes preferred for initial cost savings.

Bituminous membrane vs EPDM roofing Infographic

productdif.com

productdif.com