Batt insulation offers an affordable, easy-to-install option made from fiberglass or mineral wool, providing effective thermal resistance in standard framing cavities. Spray foam insulation expands on contact, creating an airtight seal that minimizes air leakage and improves energy efficiency while also acting as a moisture barrier. Choosing between batt insulation and spray foam depends on factors like budget, installation complexity, and desired R-value for your building project.

Table of Comparison

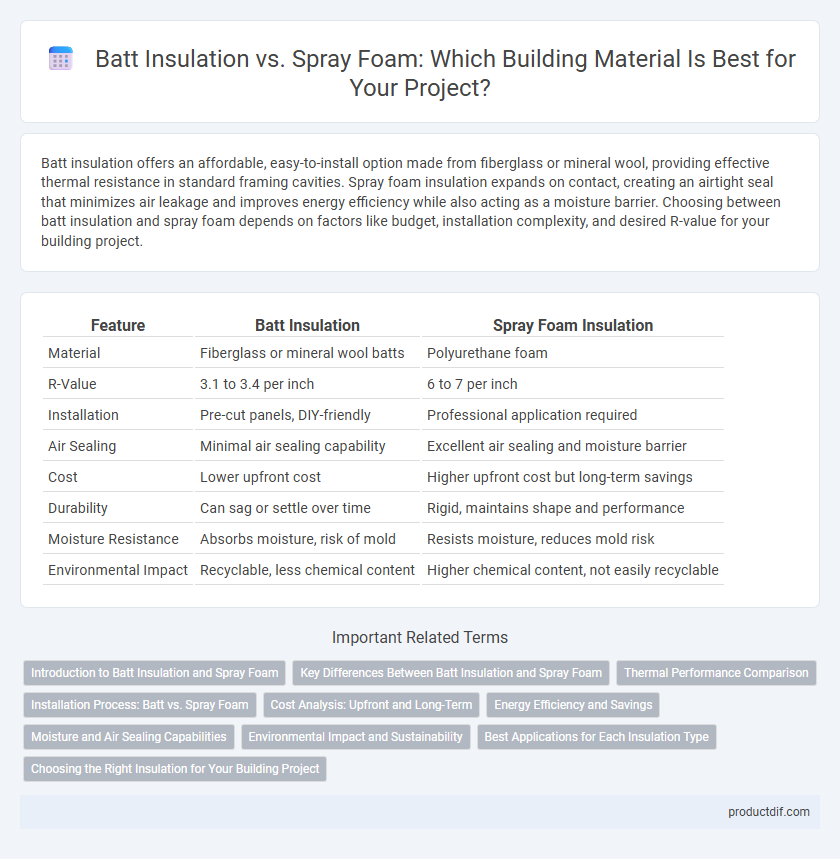

| Feature | Batt Insulation | Spray Foam Insulation |

|---|---|---|

| Material | Fiberglass or mineral wool batts | Polyurethane foam |

| R-Value | 3.1 to 3.4 per inch | 6 to 7 per inch |

| Installation | Pre-cut panels, DIY-friendly | Professional application required |

| Air Sealing | Minimal air sealing capability | Excellent air sealing and moisture barrier |

| Cost | Lower upfront cost | Higher upfront cost but long-term savings |

| Durability | Can sag or settle over time | Rigid, maintains shape and performance |

| Moisture Resistance | Absorbs moisture, risk of mold | Resists moisture, reduces mold risk |

| Environmental Impact | Recyclable, less chemical content | Higher chemical content, not easily recyclable |

Introduction to Batt Insulation and Spray Foam

Batt insulation, typically made from fiberglass or mineral wool, is a cost-effective material used in walls, ceilings, and floors to reduce heat transfer and improve energy efficiency. Spray foam insulation, composed of polyurethane, expands on application to fill gaps and provide superior air sealing, resulting in higher R-values per inch compared to batt insulation. Choosing between batt and spray foam depends on factors such as budget, installation complexity, and desired thermal performance.

Key Differences Between Batt Insulation and Spray Foam

Batt insulation consists of pre-cut panels made from fiberglass or mineral wool, offering moderate thermal resistance and soundproofing at a lower cost than spray foam. Spray foam insulation, available as open-cell or closed-cell types, expands upon application to create an air-tight seal with superior R-values, moisture resistance, and durability. The choice between batt insulation and spray foam hinges on budget, installation complexity, energy efficiency goals, and specific project requirements regarding air infiltration and thermal performance.

Thermal Performance Comparison

Batt insulation typically offers an R-value between R-2.9 and R-3.8 per inch, making it effective for moderate thermal resistance in walls and ceilings. Spray foam insulation provides a higher R-value, ranging from R-3.5 to R-6.5 per inch, resulting in superior air sealing and thermal performance that reduces energy loss. The enhanced density and expansion properties of spray foam contribute to better insulation continuity and minimized thermal bridging compared to batt insulation.

Installation Process: Batt vs. Spray Foam

Batt insulation involves cutting and fitting pre-cut fiberglass or mineral wool panels between wall studs, demanding precise measurements and careful handling to avoid gaps and compression, which can reduce its thermal efficiency. Spray foam insulation requires professional application using specialized equipment to spray liquid foam that expands and hardens in place, creating an airtight seal with superior coverage in irregular or tight spaces. The installation time for spray foam is generally faster and less labor-intensive, but it typically comes at a higher cost compared to the more DIY-friendly batt insulation.

Cost Analysis: Upfront and Long-Term

Batt insulation typically has a lower upfront cost, ranging from $0.30 to $0.50 per square foot, making it a budget-friendly option for initial installation. Spray foam insulation, while costing between $1.00 and $3.00 per square foot upfront, provides superior air sealing and higher R-values, leading to substantial long-term energy savings. Over time, the decreased heating and cooling expenses with spray foam can offset its higher initial investment, offering better cost efficiency in energy consumption.

Energy Efficiency and Savings

Batt insulation provides reliable thermal resistance with typical R-values ranging from R-11 to R-38, offering consistent energy savings in walls and ceilings. Spray foam insulation delivers superior air sealing and higher R-values per inch, often between R-6 and R-7, significantly reducing heat loss and lowering energy bills. Homes insulated with spray foam experience enhanced energy efficiency by preventing air infiltration and moisture buildup, resulting in long-term cost savings on heating and cooling.

Moisture and Air Sealing Capabilities

Batt insulation provides moderate moisture resistance but can allow air leaks through gaps if not properly installed, which may lead to condensation and mold growth in walls. Spray foam insulation offers superior air sealing by expanding to fill cracks and voids, significantly reducing moisture infiltration and improving overall energy efficiency. Its closed-cell variant acts as a vapor barrier, preventing water vapor from penetrating building envelopes and enhancing durability.

Environmental Impact and Sustainability

Batt insulation, typically made from fiberglass or mineral wool, offers moderate thermal performance with lower embodied energy compared to spray foam, making it a more environmentally friendly option in terms of material production. Spray foam insulation, composed of polyurethane, has higher global warming potential due to its use of blowing agents and long-term chemical stability, but provides superior air sealing and energy efficiency that can reduce overall carbon footprint during building operation. Choosing between batt insulation and spray foam requires evaluating lifecycle environmental impacts, including raw material sourcing, installation emissions, and long-term energy savings for sustainable building practices.

Best Applications for Each Insulation Type

Batt insulation is most effective in standard wall cavities, floors, and ceilings where uniform thickness and easy installation between studs or joists are required, making it ideal for new construction and DIY projects. Spray foam insulation excels in irregular spaces, hard-to-reach areas, and locations needing superior air sealing and higher R-values, such as attic rafters, crawl spaces, and around plumbing or electrical penetrations. Choosing the right insulation depends on project specifics, with batt providing cost-efficient thermal resistance and spray foam offering enhanced energy efficiency and moisture control.

Choosing the Right Insulation for Your Building Project

Batt insulation offers cost-effective installation and consistent thermal performance, making it ideal for standard wall cavities in residential construction. Spray foam insulation provides superior air sealing and higher R-values per inch, enhancing energy efficiency in irregular spaces and areas prone to moisture infiltration. Selecting the right insulation depends on factors such as budget, climate, building design, and desired energy savings.

Batt Insulation vs Spray Foam Infographic

productdif.com

productdif.com