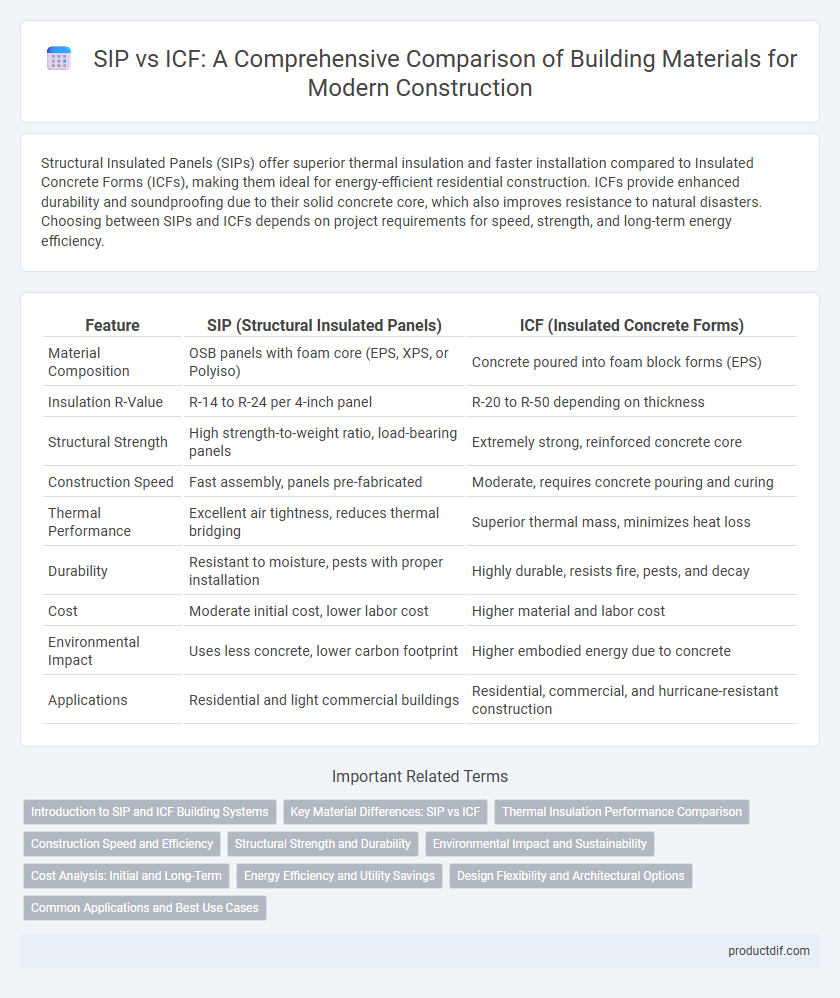

Structural Insulated Panels (SIPs) offer superior thermal insulation and faster installation compared to Insulated Concrete Forms (ICFs), making them ideal for energy-efficient residential construction. ICFs provide enhanced durability and soundproofing due to their solid concrete core, which also improves resistance to natural disasters. Choosing between SIPs and ICFs depends on project requirements for speed, strength, and long-term energy efficiency.

Table of Comparison

| Feature | SIP (Structural Insulated Panels) | ICF (Insulated Concrete Forms) |

|---|---|---|

| Material Composition | OSB panels with foam core (EPS, XPS, or Polyiso) | Concrete poured into foam block forms (EPS) |

| Insulation R-Value | R-14 to R-24 per 4-inch panel | R-20 to R-50 depending on thickness |

| Structural Strength | High strength-to-weight ratio, load-bearing panels | Extremely strong, reinforced concrete core |

| Construction Speed | Fast assembly, panels pre-fabricated | Moderate, requires concrete pouring and curing |

| Thermal Performance | Excellent air tightness, reduces thermal bridging | Superior thermal mass, minimizes heat loss |

| Durability | Resistant to moisture, pests with proper installation | Highly durable, resists fire, pests, and decay |

| Cost | Moderate initial cost, lower labor cost | Higher material and labor cost |

| Environmental Impact | Uses less concrete, lower carbon footprint | Higher embodied energy due to concrete |

| Applications | Residential and light commercial buildings | Residential, commercial, and hurricane-resistant construction |

Introduction to SIP and ICF Building Systems

Structural Insulated Panels (SIPs) consist of rigid foam insulation sandwiched between two oriented strand board (OSB) layers, providing high thermal efficiency and rapid construction for walls, roofs, and floors. Insulated Concrete Forms (ICFs) are hollow foam blocks or panels that stack to create forms for pouring reinforced concrete, combining insulation and structural strength in one system. Both SIPs and ICFs offer superior energy performance, air tightness, and durability compared to traditional framing methods in modern building materials.

Key Material Differences: SIP vs ICF

Structural Insulated Panels (SIP) consist of an insulating foam core sandwiched between two oriented strand board (OSB) facings, offering superior thermal insulation and quick assembly. Insulated Concrete Forms (ICF) use rigid foam blocks filled with reinforced concrete, providing enhanced structural strength, fire resistance, and soundproofing. SIPs prioritize lightweight construction and energy efficiency, whereas ICFs emphasize durability and load-bearing capacity in building envelopes.

Thermal Insulation Performance Comparison

Structural Insulated Panels (SIPs) typically offer higher R-values per inch compared to Insulated Concrete Forms (ICFs), enhancing thermal insulation efficiency. SIPs provide continuous insulation with minimal thermal bridging, resulting in superior energy savings in residential and commercial buildings. ICFs, while robust and durable, often show slightly lower insulation performance but excel in thermal mass, contributing to temperature regulation over time.

Construction Speed and Efficiency

Structural Insulated Panels (SIPs) significantly reduce construction time due to their prefabricated nature, allowing for rapid assembly and minimal on-site labor compared to Insulated Concrete Forms (ICFs), which require multiple steps such as stacking forms and pouring concrete. SIPs provide superior energy efficiency with continuous insulation and airtightness, minimizing thermal bridging, while ICFs offer robust thermal mass but involve longer curing times that can delay project schedules. Choosing SIPs enhances overall construction speed and operational efficiency, particularly in projects with tight timelines and labor constraints.

Structural Strength and Durability

Structural Insulated Panels (SIPs) provide high strength-to-weight ratios, offering exceptional load-bearing capacity through their rigid foam cores and OSB facings, which enhances overall building stability. Insulated Concrete Forms (ICFs) deliver superior durability with reinforced concrete cores that resist impacts, fire, and moisture infiltration, ensuring long-lasting performance under harsh conditions. While SIPs excel in lightweight structural efficiency, ICFs outperform in terms of long-term resilience and resistance to environmental stressors.

Environmental Impact and Sustainability

Structural Insulated Panels (SIPs) offer superior energy efficiency due to their airtight construction and high R-values, reducing heating and cooling demands throughout a building's lifecycle. Insulated Concrete Forms (ICFs) provide exceptional durability and thermal mass, which enhances energy conservation while using recycled concrete materials that lower environmental footprints. Both SIPs and ICFs contribute significantly to sustainable building practices by minimizing waste, promoting energy savings, and supporting LEED certification goals.

Cost Analysis: Initial and Long-Term

Structural Insulated Panels (SIPs) often present higher initial costs compared to Insulated Concrete Forms (ICFs) due to material and manufacturing expenses, but SIPs can reduce labor costs through faster installation. ICFs typically require more extensive labor and formwork, increasing upfront costs, yet they offer long-term savings through superior durability, energy efficiency, and reduced maintenance. Lifecycle cost analysis reveals that while SIPs lower initial investment and construction time, ICFs provide greater financial benefits over extended periods by enhancing building envelope performance and resisting environmental damage.

Energy Efficiency and Utility Savings

Structural Insulated Panels (SIPs) provide superior airtightness and thermal insulation compared to Insulated Concrete Forms (ICFs), resulting in lower heating and cooling costs. SIPs typically achieve higher R-values per inch, enhancing energy efficiency and reducing utility bills significantly over time. ICFs offer robust thermal mass, which stabilizes indoor temperatures but may not deliver the same immediate insulation savings as SIPs in highly insulated building envelopes.

Design Flexibility and Architectural Options

Structural Insulated Panels (SIPs) offer greater design flexibility compared to Insulated Concrete Forms (ICFs) due to their lightweight nature and ease of customization, enabling intricate shapes and unique architectural features. ICFs provide robust thermal insulation and structural strength but often limit complex geometries to standard block shapes, restricting innovative design options. Architects favor SIPs when precision, rapid installation, and diverse aesthetic possibilities are prioritized in modern building projects.

Common Applications and Best Use Cases

Structural Insulated Panels (SIPs) are commonly used in residential construction for walls, roofs, and floors due to their high thermal insulation and quick assembly, making them ideal for energy-efficient homes and modular buildings. Insulated Concrete Forms (ICFs) are best suited for foundations, basements, and load-bearing walls in commercial and residential construction, providing superior strength, durability, and excellent soundproofing. Both SIPs and ICFs excel in creating airtight, energy-efficient structures but differ in application focus: SIPs prioritize lightweight, fast construction, while ICFs emphasize robust, long-lasting support.

SIP vs ICF Infographic

productdif.com

productdif.com