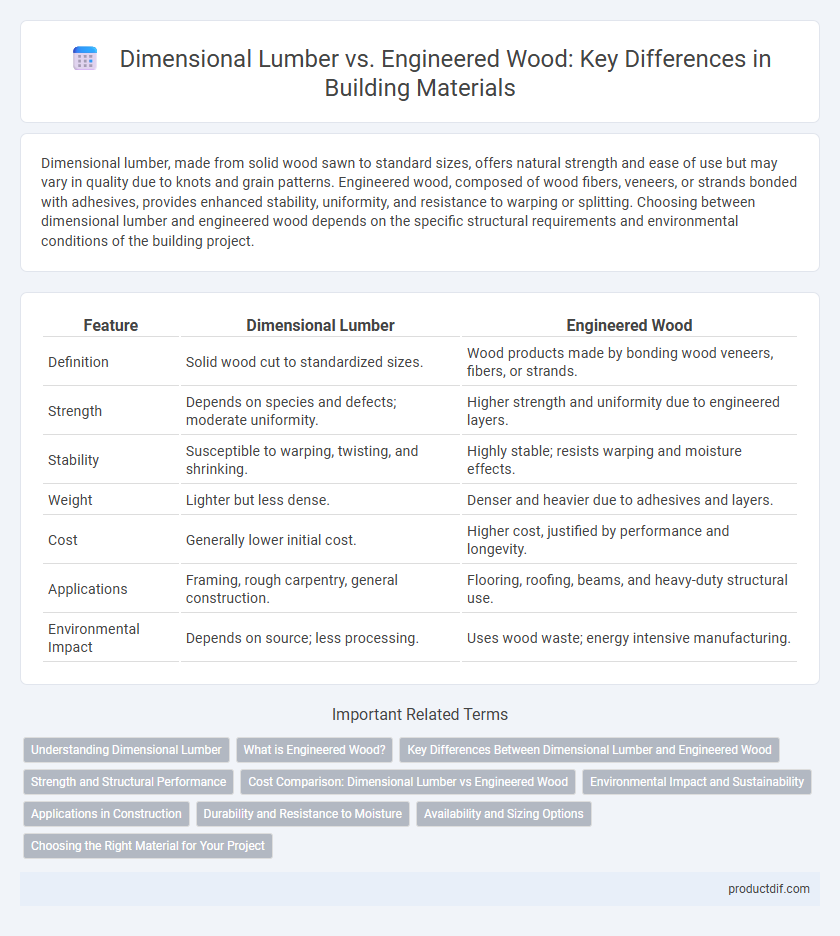

Dimensional lumber, made from solid wood sawn to standard sizes, offers natural strength and ease of use but may vary in quality due to knots and grain patterns. Engineered wood, composed of wood fibers, veneers, or strands bonded with adhesives, provides enhanced stability, uniformity, and resistance to warping or splitting. Choosing between dimensional lumber and engineered wood depends on the specific structural requirements and environmental conditions of the building project.

Table of Comparison

| Feature | Dimensional Lumber | Engineered Wood |

|---|---|---|

| Definition | Solid wood cut to standardized sizes. | Wood products made by bonding wood veneers, fibers, or strands. |

| Strength | Depends on species and defects; moderate uniformity. | Higher strength and uniformity due to engineered layers. |

| Stability | Susceptible to warping, twisting, and shrinking. | Highly stable; resists warping and moisture effects. |

| Weight | Lighter but less dense. | Denser and heavier due to adhesives and layers. |

| Cost | Generally lower initial cost. | Higher cost, justified by performance and longevity. |

| Applications | Framing, rough carpentry, general construction. | Flooring, roofing, beams, and heavy-duty structural use. |

| Environmental Impact | Depends on source; less processing. | Uses wood waste; energy intensive manufacturing. |

Understanding Dimensional Lumber

Dimensional lumber consists of solid wood pieces cut to standardized widths and depths, commonly used for framing and structural support in construction. It offers natural strength and stiffness, but its quality can vary due to knots, warping, and other imperfections inherent in wood. Understanding the properties and limitations of dimensional lumber is essential for selecting the right material and ensuring structural integrity in building projects.

What is Engineered Wood?

Engineered wood consists of composite materials made by binding wood fibers, strands, or veneers with adhesives to create stronger, more uniform panels compared to traditional dimensional lumber. Common types include plywood, oriented strand board (OSB), laminated veneer lumber (LVL), and cross-laminated timber (CLT), each offering enhanced stability, resistance to warping, and greater structural performance. Engineered wood's optimized strength-to-weight ratio and versatility make it a preferred choice in modern construction for framing, flooring, and roofing applications.

Key Differences Between Dimensional Lumber and Engineered Wood

Dimensional lumber is solid wood cut to standardized sizes, offering natural strength and ease of use, while engineered wood is manufactured from wood fibers, strands, or veneers bonded with adhesives to enhance uniformity and performance. Engineered wood provides greater resistance to warping, splitting, and shrinking compared to dimensional lumber, making it ideal for structural applications requiring stability. The cost and environmental impact differ since engineered wood often utilizes recycled materials and maximizes raw resource efficiency, whereas dimensional lumber depends on larger, high-quality timber.

Strength and Structural Performance

Dimensional lumber offers natural strength and uniformity in load-bearing applications, but engineered wood provides enhanced structural performance through precise manufacturing processes that optimize strength-to-weight ratios. Engineered wood products, such as laminated veneer lumber (LVL) and glue-laminated timber (glulam), exhibit superior resistance to warping, twisting, and splitting compared to traditional solid sawn lumber. In critical structural projects, engineered wood ensures greater durability and load capacity, making it ideal for beams, joists, and framing where consistent strength is essential.

Cost Comparison: Dimensional Lumber vs Engineered Wood

Dimensional lumber typically costs less upfront than engineered wood, making it a budget-friendly option for many construction projects. Engineered wood, while more expensive initially, offers greater strength and stability, reducing long-term repair and replacement costs. Project-specific factors such as span requirements and environmental conditions influence the overall cost-effectiveness of both materials.

Environmental Impact and Sustainability

Dimensional lumber, sourced from solid wood, typically has a lower embodied energy compared to engineered wood, which involves energy-intensive manufacturing processes. Engineered wood products often utilize wood fibers and adhesives efficiently, reducing waste and promoting sustainable forest management practices through optimized material usage. Choosing between the two depends on balancing carbon footprint considerations, resource renewability, and long-term durability in construction projects.

Applications in Construction

Dimensional lumber, known for its uniform size and natural wood grain, is widely used in framing walls, floors, and roofs where structural strength and ease of modification are essential. Engineered wood products, such as laminated veneer lumber (LVL) and oriented strand board (OSB), offer superior load-bearing capacity and stability, making them ideal for long-span beams, roof trusses, and floor joists in modern construction. Both materials contribute to sustainable building by optimizing resource use and enhancing structural performance in residential and commercial projects.

Durability and Resistance to Moisture

Dimensional lumber is made from solid wood and offers natural strength but is more susceptible to warping and moisture damage over time. Engineered wood, such as plywood or laminated veneer lumber (LVL), incorporates adhesives and multiple wood layers, providing enhanced durability and superior moisture resistance. This makes engineered wood a preferred choice in environments with high humidity or frequent water exposure.

Availability and Sizing Options

Dimensional lumber is widely available in standard sizes such as 2x4, 2x6, and 2x8, making it easy to source at most lumberyards and home improvement stores. Engineered wood products, like laminated veneer lumber (LVL) and I-joists, offer greater sizing flexibility with custom lengths and widths tailored to specific structural needs. Availability of engineered wood varies by supplier but is increasingly common due to its strength-to-weight ratio and resistance to warping compared to traditional dimensional lumber.

Choosing the Right Material for Your Project

Dimensional lumber offers natural strength and traditional aesthetics, making it ideal for load-bearing structures and visible framing. Engineered wood provides consistent quality, enhanced durability, and resistance to warping, suitable for complex designs and longer spans. Selecting the right material depends on project requirements such as structural load, environmental conditions, and budget constraints.

Dimensional Lumber vs Engineered Wood Infographic

productdif.com

productdif.com