Self-leveling concrete offers faster installation and superior surface smoothness compared to traditional screed, reducing labor costs and time. Its flowable consistency allows for even distribution over uneven substrates, ensuring a flat and durable finish ideal for high-traffic areas. Traditional screed requires more manual effort to level and cure, making it less efficient for modern construction demands.

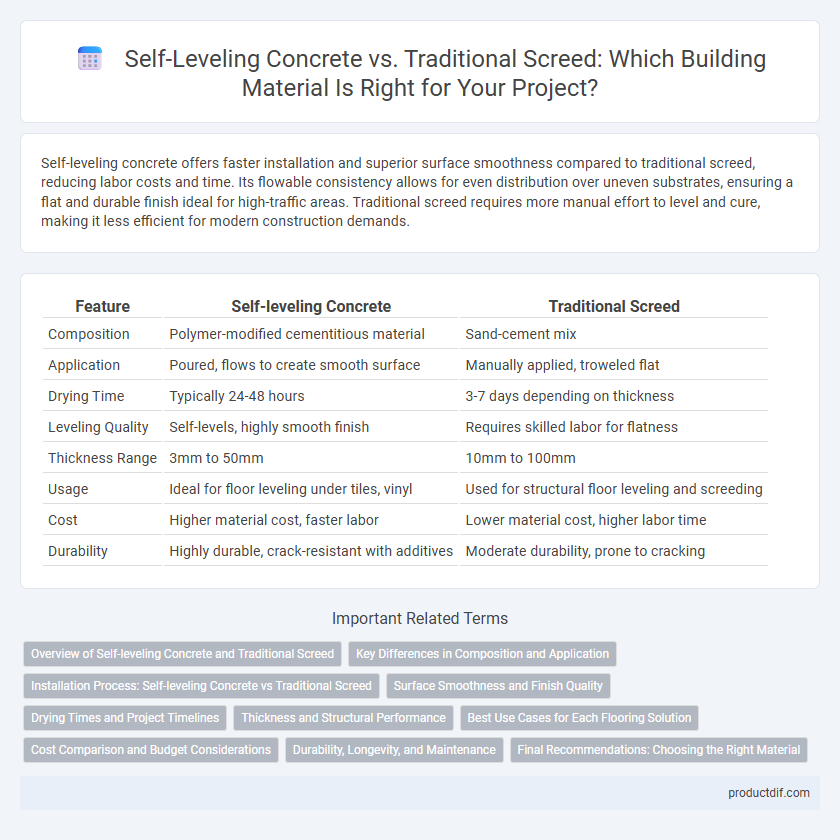

Table of Comparison

| Feature | Self-leveling Concrete | Traditional Screed |

|---|---|---|

| Composition | Polymer-modified cementitious material | Sand-cement mix |

| Application | Poured, flows to create smooth surface | Manually applied, troweled flat |

| Drying Time | Typically 24-48 hours | 3-7 days depending on thickness |

| Leveling Quality | Self-levels, highly smooth finish | Requires skilled labor for flatness |

| Thickness Range | 3mm to 50mm | 10mm to 100mm |

| Usage | Ideal for floor leveling under tiles, vinyl | Used for structural floor leveling and screeding |

| Cost | Higher material cost, faster labor | Lower material cost, higher labor time |

| Durability | Highly durable, crack-resistant with additives | Moderate durability, prone to cracking |

Overview of Self-leveling Concrete and Traditional Screed

Self-leveling concrete is a polymer-modified mixture designed to flow and level itself without mechanical compaction, providing a smooth and durable surface ideal for modern flooring systems. Traditional screed consists of a sand and cement mixture that requires manual leveling and compaction, often resulting in uneven surfaces and longer drying times. Self-leveling concrete offers enhanced flatness, faster installation, and superior strength compared to traditional screed, making it preferable for advanced construction projects.

Key Differences in Composition and Application

Self-leveling concrete contains polymer modifiers and fine aggregates, enabling rapid flow and self-smoothing properties without extensive manual finishing, unlike traditional screed, which relies on cement, sand, and water mixtures applied and leveled manually. The quick-setting nature of self-leveling concrete reduces installation time, making it ideal for thin overlays and complex floor preparations, while traditional screed requires longer curing periods and is better suited for thicker, structural subfloors. Application of self-leveling concrete demands primer use and precise mixing ratios, whereas traditional screed offers more flexibility in on-site adjustments but less uniform surface finish.

Installation Process: Self-leveling Concrete vs Traditional Screed

Self-leveling concrete offers a faster installation process by flowing smoothly over surfaces and requiring minimal manual leveling, reducing labor time and costs. Traditional screed demands more extensive manual work, involving spreading, leveling, and multiple drying stages that extend the overall project duration. The rapid curing time of self-leveling concrete allows for quicker subsequent flooring applications compared to the longer wait times necessary for traditional screed to fully set.

Surface Smoothness and Finish Quality

Self-leveling concrete provides superior surface smoothness and finish quality compared to traditional screed due to its fluid consistency, which allows it to flow evenly and fill gaps without leaving trowel marks. The faster curing time and enhanced leveling capabilities of self-leveling concrete result in a consistently flat substrate ideal for tile, carpet, or hardwood installation. Traditional screed often requires extensive manual smoothing and can leave uneven surfaces prone to cracking and uneven finishes.

Drying Times and Project Timelines

Self-leveling concrete typically dries within 24 to 48 hours, significantly accelerating project timelines compared to traditional screed, which can require up to 7 days to fully cure. Faster drying times with self-leveling concrete reduce labor costs and allow for earlier installation of finishing materials like tiles or hardwood flooring. Choosing self-leveling concrete optimizes construction schedules in commercial and residential projects by minimizing downtime and ensuring quicker project completion.

Thickness and Structural Performance

Self-leveling concrete typically requires a thinner application layer, often between 3 to 10 mm, compared to traditional screed which usually ranges from 25 to 50 mm, enhancing speed and material efficiency. The polymer-modified composition of self-leveling concrete offers superior bond strength and flexural performance, reducing the risk of cracking and improving durability under load. Traditional screed's greater thickness provides substantial load-bearing capacity but may suffer from longer curing times and susceptibility to shrinkage cracks, affecting long-term structural integrity.

Best Use Cases for Each Flooring Solution

Self-leveling concrete is ideal for fast, smooth finishes on uneven or damaged subfloors, often used in commercial spaces and under tile or vinyl flooring due to its quick curing time and high flowability. Traditional screed suits thicker applications and is preferable for outdoor patios or large floor areas requiring structural strength and durability. Choosing based on project scale and finish requirements optimizes performance and longevity for each flooring solution.

Cost Comparison and Budget Considerations

Self-leveling concrete generally incurs higher initial costs compared to traditional screed due to specialized additives and application techniques but offers faster installation and reduced labor expenses, potentially lowering overall project budgets. Traditional screed tends to be more budget-friendly upfront, making it suitable for large-scale projects with limited funding, although longer drying times may increase indirect costs. Evaluating total project expenses including material, labor, and time-related factors is critical in choosing the most cost-effective flooring solution.

Durability, Longevity, and Maintenance

Self-leveling concrete offers superior durability compared to traditional screed due to its higher resistance to cracking, moisture penetration, and wear from heavy foot traffic. It significantly extends longevity by creating a more uniform and dense surface that minimizes the risk of surface degradation over time. Maintenance is reduced with self-leveling concrete as its smooth finish requires less frequent repairs and can withstand harsh environmental conditions better than traditional screed.

Final Recommendations: Choosing the Right Material

Self-leveling concrete offers superior flowability and rapid curing, making it ideal for fast-paced projects requiring smooth, even floors with minimal preparation. Traditional screed remains a cost-effective solution for thicker applications and where extended drying times are acceptable, especially in renovation settings. Selecting the right material depends on project timeline, surface requirements, and budget constraints to ensure optimal performance and durability.

Self-leveling Concrete vs Traditional Screed Infographic

productdif.com

productdif.com