TPO roofing offers superior energy efficiency and heat reflection compared to EPDM roofing, making it ideal for reducing cooling costs in commercial buildings. EPDM roofing provides exceptional durability and resistance to UV radiation and weathering, often lasting longer in harsh climates. Both materials are popular choices for sustainable construction, but the selection depends on specific project requirements such as budget, lifespan, and environmental conditions.

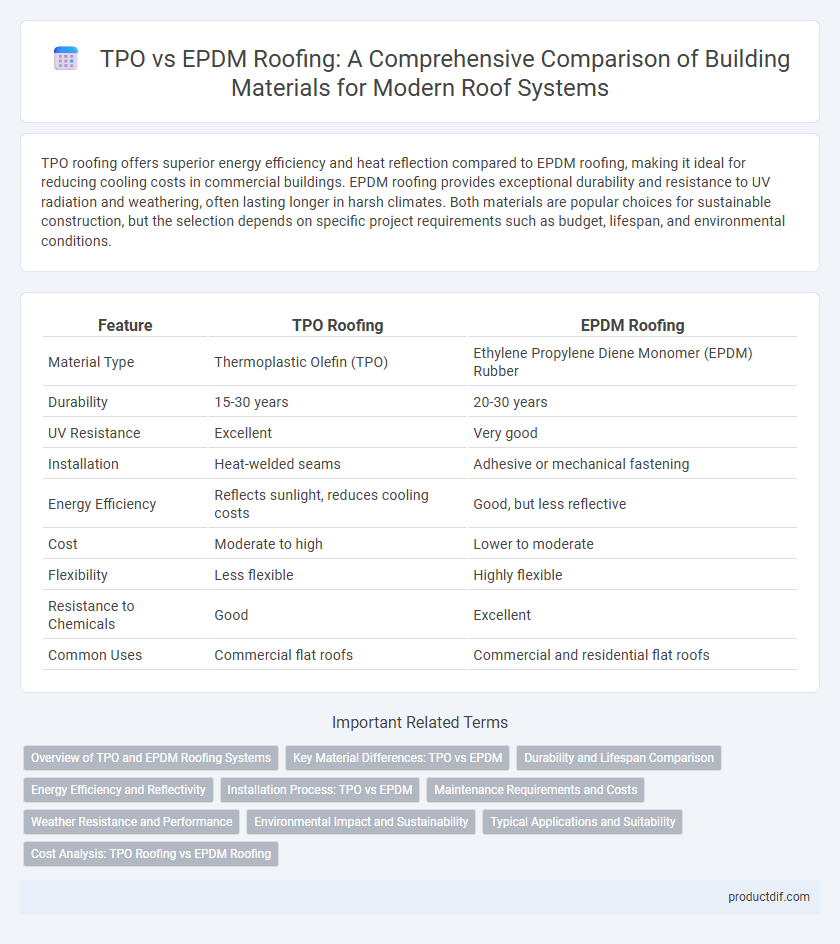

Table of Comparison

| Feature | TPO Roofing | EPDM Roofing |

|---|---|---|

| Material Type | Thermoplastic Olefin (TPO) | Ethylene Propylene Diene Monomer (EPDM) Rubber |

| Durability | 15-30 years | 20-30 years |

| UV Resistance | Excellent | Very good |

| Installation | Heat-welded seams | Adhesive or mechanical fastening |

| Energy Efficiency | Reflects sunlight, reduces cooling costs | Good, but less reflective |

| Cost | Moderate to high | Lower to moderate |

| Flexibility | Less flexible | Highly flexible |

| Resistance to Chemicals | Good | Excellent |

| Common Uses | Commercial flat roofs | Commercial and residential flat roofs |

Overview of TPO and EPDM Roofing Systems

TPO roofing systems consist of thermoplastic polyolefin membranes known for their heat-reflective properties, durability, and energy efficiency, making them ideal for commercial buildings. EPDM roofing features ethylene propylene diene monomer rubber, prized for exceptional weather resistance, flexibility, and ease of installation, particularly in colder climates. Both materials offer distinct advantages in lifespan and maintenance, with TPO often favored for its modern composition and EPDM for its proven reliability.

Key Material Differences: TPO vs EPDM

TPO roofing is made from a single-ply thermoplastic polymer blend, offering superior resistance to UV radiation, chemical exposure, and punctures, while EPDM roofing consists of a durable synthetic rubber membrane known for excellent weathering and ozone resistance. TPO membranes are typically white or light-colored, enhancing energy efficiency through heat reflection, whereas EPDM is commonly black, providing better heat absorption. The distinct polymer chemistry in TPO allows for heat welding seams, creating stronger bonds compared to the glued or taped seams used in EPDM installations.

Durability and Lifespan Comparison

TPO roofing offers a lifespan of 15 to 30 years, characterized by strong resistance to UV rays, chemical exposure, and punctures, making it highly durable for commercial buildings. EPDM roofing typically lasts 20 to 30 years with exceptional flexibility and weather resistance, especially in extreme temperature variations. Both materials provide long-lasting protection, but EPDM's enhanced elasticity can result in fewer repairs over the roof's lifetime.

Energy Efficiency and Reflectivity

TPO roofing offers superior energy efficiency due to its high solar reflectance, which can reduce cooling costs by reflecting more ultraviolet and infrared rays compared to EPDM roofing. EPDM roofing, while durable, absorbs more heat, leading to higher surface temperatures and increased energy consumption for cooling. Choosing TPO roofing enhances building sustainability by lowering heat buildup and improving overall energy savings.

Installation Process: TPO vs EPDM

TPO roofing involves heat-welding seams to create a watertight bond, which requires specialized equipment and skilled labor, resulting in faster, more uniform installation compared to EPDM. EPDM roofing utilizes adhesive or mechanical fasteners to secure the membrane, making the process more flexible but generally more labor-intensive and time-consuming. TPO's heat-welded seams provide enhanced durability, while EPDM's simpler installation allows for easier repairs and modifications on-site.

Maintenance Requirements and Costs

TPO roofing requires less frequent maintenance due to its resistance to UV rays and chemical exposure, resulting in lower long-term upkeep costs compared to EPDM roofing. EPDM roofing, while known for durability, often demands more regular inspections and repairs to address potential seam failures and punctures, increasing maintenance expenses over time. Cost analysis shows TPO roofing typically offers better value in maintenance efficiency, though initial installation costs may vary based on project specifications.

Weather Resistance and Performance

TPO roofing membranes exhibit superior UV resistance and reflectivity, reducing heat absorption and prolonging roof lifespan in extreme weather conditions. EPDM roofing offers exceptional flexibility and resistance to hail, ozone, and thermal shock, maintaining performance in colder climates. Both materials demonstrate strong durability, but TPO excels in hot, sunny environments while EPDM performs better in areas with significant temperature fluctuations.

Environmental Impact and Sustainability

TPO roofing offers superior environmental benefits due to its fully recyclable composition and energy-efficient reflective properties, which reduce heat absorption and decrease cooling costs. EPDM roofing, while durable and recyclable, typically has a higher embodied energy and less reflective surface, leading to increased urban heat island effects. Both materials contribute to sustainable building practices, but TPO's lower environmental footprint and potential for LEED certification make it a more eco-friendly choice.

Typical Applications and Suitability

TPO roofing is commonly used for commercial buildings with flat or low-slope roofs, offering excellent heat-reflective properties and resistance to UV rays, making it ideal for warm climates and energy-efficient constructions. EPDM roofing excels in environments requiring superior durability and weather resistance, suited for both commercial and residential applications, especially in areas with extreme weather conditions due to its excellent ozone and chemical resistance. Both materials provide effective waterproofing, but TPO is preferred for new installations prioritizing energy savings, while EPDM is favored for retrofit projects demanding long-lasting flexibility.

Cost Analysis: TPO Roofing vs EPDM Roofing

TPO roofing typically costs between $5.50 and $9.00 per square foot, making it a more affordable option compared to EPDM roofing, which ranges from $6.00 to $12.00 per square foot. Installation expenses for TPO are usually lower due to its lightweight and heat-weldable seams, while EPDM requires specialized adhesives that increase labor costs. Long-term maintenance costs are generally higher for EPDM because of its vulnerability to punctures and weathering, whereas TPO offers better resistance to UV exposure and chemical damage, reducing repair frequency.

TPO roofing vs EPDM roofing Infographic

productdif.com

productdif.com