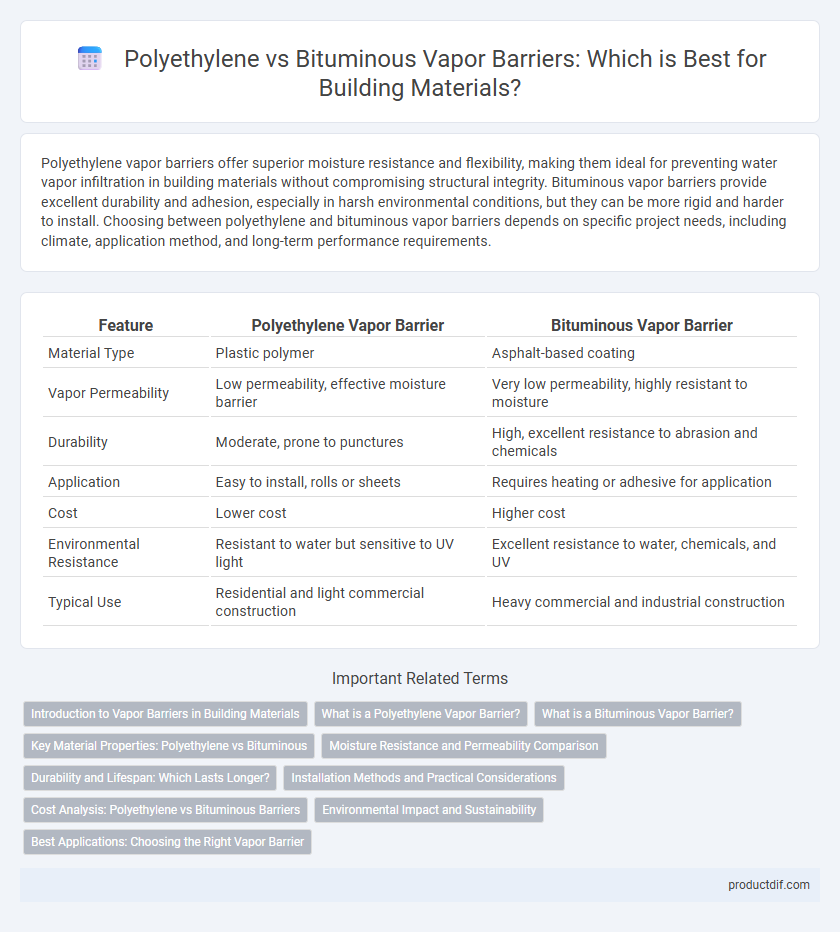

Polyethylene vapor barriers offer superior moisture resistance and flexibility, making them ideal for preventing water vapor infiltration in building materials without compromising structural integrity. Bituminous vapor barriers provide excellent durability and adhesion, especially in harsh environmental conditions, but they can be more rigid and harder to install. Choosing between polyethylene and bituminous vapor barriers depends on specific project needs, including climate, application method, and long-term performance requirements.

Table of Comparison

| Feature | Polyethylene Vapor Barrier | Bituminous Vapor Barrier |

|---|---|---|

| Material Type | Plastic polymer | Asphalt-based coating |

| Vapor Permeability | Low permeability, effective moisture barrier | Very low permeability, highly resistant to moisture |

| Durability | Moderate, prone to punctures | High, excellent resistance to abrasion and chemicals |

| Application | Easy to install, rolls or sheets | Requires heating or adhesive for application |

| Cost | Lower cost | Higher cost |

| Environmental Resistance | Resistant to water but sensitive to UV light | Excellent resistance to water, chemicals, and UV |

| Typical Use | Residential and light commercial construction | Heavy commercial and industrial construction |

Introduction to Vapor Barriers in Building Materials

Polyethylene vapor barriers are lightweight, flexible sheets with excellent moisture resistance, commonly used in residential and commercial construction to prevent water vapor penetration. Bituminous vapor barriers, composed of bitumen-based materials, offer superior durability and waterproofing properties, making them ideal for heavy-duty applications such as roofing and foundation protection. Selecting the appropriate vapor barrier depends on factors like environmental conditions, building design, and cost-effectiveness, ensuring optimal moisture control in the building envelope.

What is a Polyethylene Vapor Barrier?

A polyethylene vapor barrier is a durable plastic sheet designed to prevent moisture from penetrating walls, floors, and ceilings in building construction. Made from high-density polyethylene (HDPE), it offers excellent resistance to water vapor transmission and is lightweight, flexible, and easy to install. Unlike bituminous vapor barriers, polyethylene barriers do not require adhesives or heat application, making them ideal for moisture control in both residential and commercial buildings.

What is a Bituminous Vapor Barrier?

A bituminous vapor barrier is a waterproofing membrane made from bitumen, a sticky, black, and viscous material derived from petroleum. Commonly used in building foundations and roofing systems, this barrier prevents moisture penetration and protects structural elements from water damage. Its durability and resistance to chemicals make it an effective solution for long-term vapor barrier needs in construction projects.

Key Material Properties: Polyethylene vs Bituminous

Polyethylene vapor barriers exhibit high tensile strength, excellent flexibility, and superior resistance to moisture penetration, making them ideal for long-term vapor control in construction. Bituminous vapor barriers provide robust adhesion properties and enhanced durability against chemical exposure but tend to have lower elasticity and can degrade under prolonged UV exposure. The choice between polyethylene and bituminous vapor barriers depends on project-specific requirements for moisture resistance, flexibility, and environmental durability.

Moisture Resistance and Permeability Comparison

Polyethylene vapor barriers exhibit superior moisture resistance with a low permeability rating typically below 0.1 perms, effectively preventing water vapor transmission in building envelopes. Bituminous vapor barriers, while also moisture-resistant, generally have higher permeability values ranging from 0.5 to 1.5 perms, allowing limited vapor diffusion. The lower permeability of polyethylene makes it more suitable for environments requiring stringent moisture control to prevent mold growth and structural deterioration.

Durability and Lifespan: Which Lasts Longer?

Polyethylene vapor barriers offer high resistance to moisture and chemical degradation, typically lasting 20 to 30 years under optimal conditions. Bituminous vapor barriers, composed of asphalt-based materials, provide enhanced durability against physical damage and UV exposure, often extending lifespan up to 40 years. The choice depends on environmental exposure and application, with bituminous barriers generally outperforming polyethylene in long-term durability.

Installation Methods and Practical Considerations

Polyethylene vapor barriers are lightweight, flexible sheets that are typically installed by unrolling and securing with staples or tape, making them suitable for quick, cost-effective application in walls and floors. Bituminous vapor barriers require heating with a torch to melt the bitumen onto the substrate, providing a durable, waterproof seal that is ideal for foundations and roofing but demands skilled labor and careful safety precautions. Polyethylene offers ease of installation with minimal equipment, whereas bituminous membranes necessitate specialized tools and fire-resistant protocols, impacting project timeline and labor costs.

Cost Analysis: Polyethylene vs Bituminous Barriers

Polyethylene vapor barriers generally offer a lower initial cost compared to bituminous vapor barriers, making them a cost-effective choice for large-scale construction projects. Bituminous barriers, while more expensive upfront due to their durability and superior waterproofing properties, can reduce long-term maintenance expenses and improve building lifespan. Evaluating total cost of ownership reveals that polyethylene suits budget-conscious applications, whereas bituminous barriers provide higher value in performance-critical environments.

Environmental Impact and Sustainability

Polyethylene vapor barriers are typically non-biodegradable and derived from fossil fuels, contributing to long-term environmental pollution, but their recyclability varies with local facilities. Bituminous vapor barriers, made from bitumen, have a lower carbon footprint due to the use of natural asphalt, although their production can release volatile organic compounds (VOCs) impacting air quality. Sustainable building practices favor materials with minimal ecological disturbance, where the choice between polyethylene and bituminous vapor barriers depends on lifecycle assessments, ecological toxicity, and disposal considerations.

Best Applications: Choosing the Right Vapor Barrier

Polyethylene vapor barriers excel in residential and commercial construction due to their high moisture resistance and affordability, making them ideal for crawl spaces, basements, and under concrete slabs. Bituminous vapor barriers offer superior durability and UV resistance, suited for roofing systems and exterior foundation walls exposed to harsher environmental conditions. Selecting the right vapor barrier depends on the specific application environment, moisture levels, and exposure to physical and chemical stressors.

Polyethylene vapor barrier vs Bituminous vapor barrier Infographic

productdif.com

productdif.com