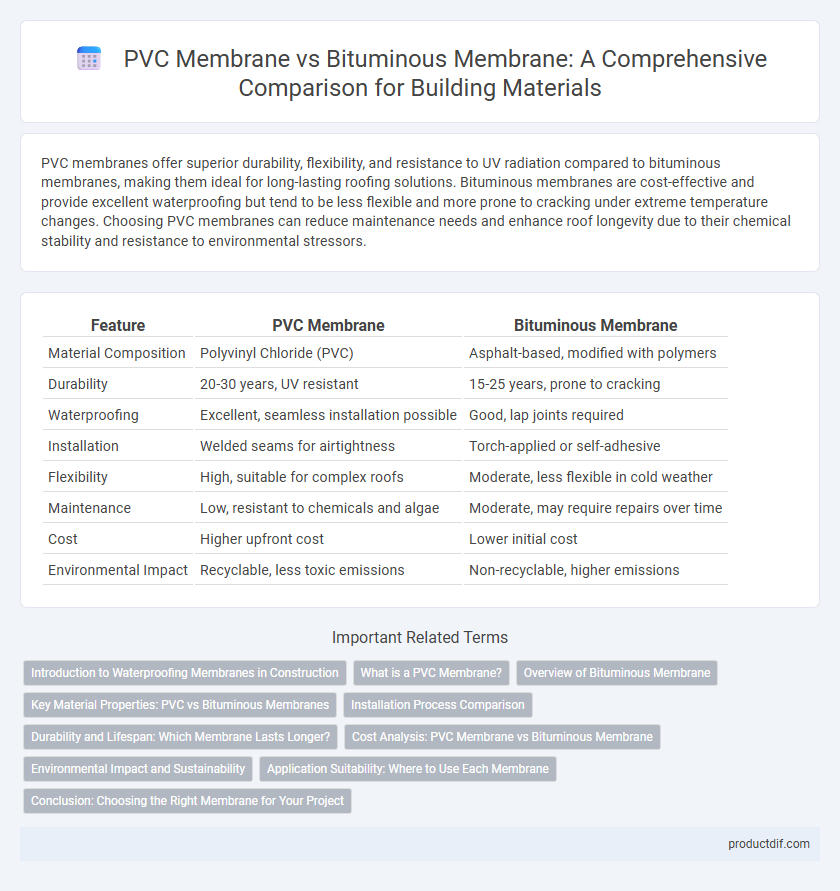

PVC membranes offer superior durability, flexibility, and resistance to UV radiation compared to bituminous membranes, making them ideal for long-lasting roofing solutions. Bituminous membranes are cost-effective and provide excellent waterproofing but tend to be less flexible and more prone to cracking under extreme temperature changes. Choosing PVC membranes can reduce maintenance needs and enhance roof longevity due to their chemical stability and resistance to environmental stressors.

Table of Comparison

| Feature | PVC Membrane | Bituminous Membrane |

|---|---|---|

| Material Composition | Polyvinyl Chloride (PVC) | Asphalt-based, modified with polymers |

| Durability | 20-30 years, UV resistant | 15-25 years, prone to cracking |

| Waterproofing | Excellent, seamless installation possible | Good, lap joints required |

| Installation | Welded seams for airtightness | Torch-applied or self-adhesive |

| Flexibility | High, suitable for complex roofs | Moderate, less flexible in cold weather |

| Maintenance | Low, resistant to chemicals and algae | Moderate, may require repairs over time |

| Cost | Higher upfront cost | Lower initial cost |

| Environmental Impact | Recyclable, less toxic emissions | Non-recyclable, higher emissions |

Introduction to Waterproofing Membranes in Construction

PVC membranes offer high durability, flexibility, and resistance to chemicals and UV radiation, making them ideal for long-term waterproofing solutions in construction. Bituminous membranes provide excellent waterproofing through their bitumen-based composition, known for high adhesion and thermal stability, commonly used in roofing and foundation protection. Choosing between PVC and bituminous membranes depends on project requirements such as environmental exposure, installation method, and lifecycle costs.

What is a PVC Membrane?

A PVC membrane is a synthetic roofing material made from polyvinyl chloride, known for its durability, flexibility, and chemical resistance. It provides excellent waterproofing performance, making it suitable for flat and low-slope roofs in commercial and residential buildings. Compared to bituminous membranes, PVC membranes offer superior UV resistance and ease of installation, contributing to longer service life and lower maintenance costs.

Overview of Bituminous Membrane

Bituminous membranes are composed of asphalt or bitumen mixed with polymers, providing excellent waterproofing and durability for roofing and foundation applications. These membranes offer superior resistance to UV radiation, thermal expansion, and mechanical stress compared to traditional PVC membranes. Commonly used in commercial and industrial buildings, bituminous membranes ensure long-term protection against water infiltration.

Key Material Properties: PVC vs Bituminous Membranes

PVC membranes offer superior flexibility and UV resistance, maintaining durability in extreme weather conditions without significant degradation. Bituminous membranes provide excellent waterproofing and adhesion to various substrates but are more prone to cracking and brittleness over time, especially under temperature fluctuations. The chemical stability of PVC ensures longer service life with lower maintenance compared to bituminous options, making it a cost-effective choice for roofing and waterproofing applications.

Installation Process Comparison

PVC membranes offer a quicker installation process due to their lightweight nature and flexibility, allowing for seamless welding with hot air tools that create strong, watertight joints. Bituminous membranes require heating with a torch or hot asphalt application, which demands skilled labor and longer curing times to ensure adhesion and prevent leaks. The ease of installing PVC membranes reduces labor costs and minimizes on-site risks compared to the more labor-intensive and hazardous bituminous membrane application.

Durability and Lifespan: Which Membrane Lasts Longer?

PVC membranes offer exceptional durability with resistance to UV rays, chemicals, and punctures, resulting in a lifespan of 20 to 30 years. Bituminous membranes, while effective against water infiltration, typically last 10 to 15 years due to susceptibility to cracking and deterioration under extreme weather conditions. The longer lifespan of PVC membranes makes them a preferred choice for sustainable roofing solutions.

Cost Analysis: PVC Membrane vs Bituminous Membrane

PVC membranes typically have a higher initial cost compared to bituminous membranes, but offer longer service life and lower maintenance expenses, making them cost-effective over time. Bituminous membranes are more affordable upfront but may require frequent repairs and replacements, increasing total life cycle costs. Evaluating total cost of ownership, including installation, maintenance, and durability, is crucial for informed decision-making between PVC and bituminous roofing membranes.

Environmental Impact and Sustainability

PVC membranes demonstrate higher environmental sustainability due to their recyclability and lower emissions during production compared to bituminous membranes, which release significant volatile organic compounds (VOCs) and greenhouse gases. Bituminous membranes are derived from petroleum, contributing to non-renewable resource depletion and environmental pollution through their extraction and disposal processes. PVC membranes offer longer lifecycle durability and potential for energy efficiency in buildings, reducing overall environmental impact over time.

Application Suitability: Where to Use Each Membrane

PVC membranes are ideal for roofing applications requiring high resistance to UV radiation, chemicals, and fire, commonly used on commercial flat roofs and green roofing systems. Bituminous membranes suit waterproofing foundations, basements, and below-grade structures due to their excellent adhesion and flexibility in cold climates. Choosing between PVC and bituminous membranes depends on factors like exposure conditions, structural requirements, and long-term durability demands.

Conclusion: Choosing the Right Membrane for Your Project

PVC membranes offer superior durability, UV resistance, and flexibility, making them ideal for long-term roofing projects in harsh climates. Bituminous membranes provide cost-effective waterproofing solutions with excellent adhesion and ease of installation, suitable for budget-sensitive, moderate-weather applications. Selecting the right membrane depends on project-specific factors such as budget, environmental exposure, and desired lifespan, ensuring optimal performance and value.

PVC membrane vs Bituminous membrane Infographic

productdif.com

productdif.com