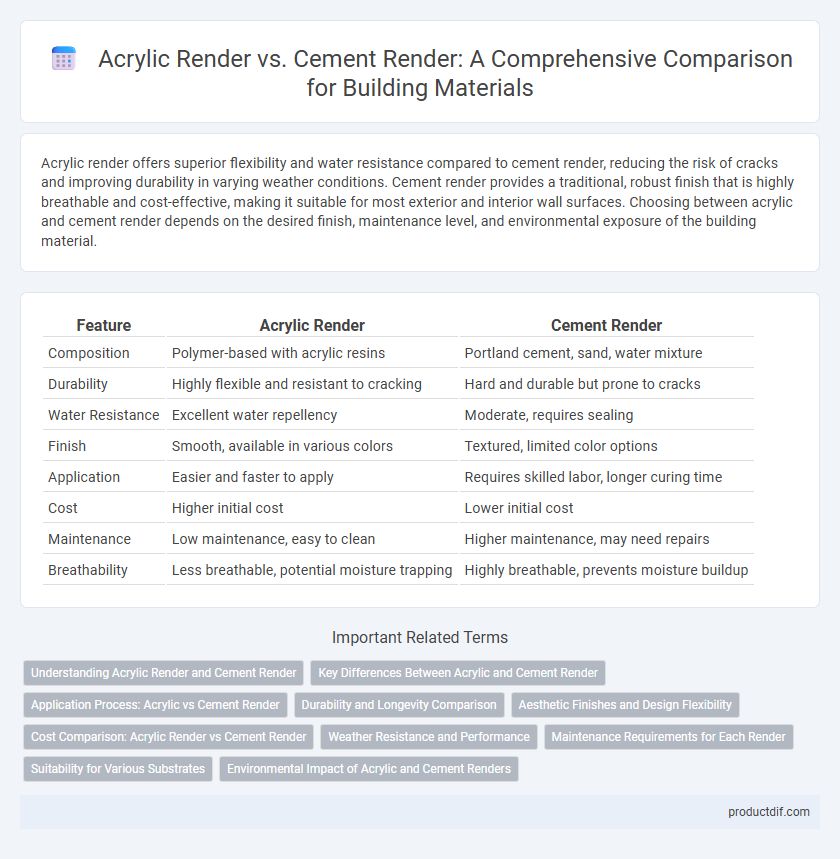

Acrylic render offers superior flexibility and water resistance compared to cement render, reducing the risk of cracks and improving durability in varying weather conditions. Cement render provides a traditional, robust finish that is highly breathable and cost-effective, making it suitable for most exterior and interior wall surfaces. Choosing between acrylic and cement render depends on the desired finish, maintenance level, and environmental exposure of the building material.

Table of Comparison

| Feature | Acrylic Render | Cement Render |

|---|---|---|

| Composition | Polymer-based with acrylic resins | Portland cement, sand, water mixture |

| Durability | Highly flexible and resistant to cracking | Hard and durable but prone to cracks |

| Water Resistance | Excellent water repellency | Moderate, requires sealing |

| Finish | Smooth, available in various colors | Textured, limited color options |

| Application | Easier and faster to apply | Requires skilled labor, longer curing time |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Low maintenance, easy to clean | Higher maintenance, may need repairs |

| Breathability | Less breathable, potential moisture trapping | Highly breathable, prevents moisture buildup |

Understanding Acrylic Render and Cement Render

Acrylic render is a polymer-based coating known for its flexibility, water resistance, and durability, making it ideal for exterior walls exposed to varying weather conditions. Cement render consists of a mixture of cement, sand, and water, offering a robust and breathable surface that provides excellent adhesion and strength for masonry substrates. Understanding these differences helps in selecting the right render based on environmental exposure, substrate type, and desired finish.

Key Differences Between Acrylic and Cement Render

Acrylic render offers superior flexibility and crack resistance compared to cement render, making it ideal for surfaces prone to movement. Cement render provides a stronger, more durable finish with better breathability, suitable for traditional masonry. Acrylic render also dries faster and is available in a wider range of colors and textures, enhancing design versatility.

Application Process: Acrylic vs Cement Render

Acrylic render offers a faster application process due to its pre-mixed formula and better adhesion to various substrates, allowing for multiple coats in a shorter timeframe. Cement render requires mixing on-site and a longer curing period, typically involving a base coat and finishing coat with careful wet curing to prevent cracking. Acrylic render's flexibility reduces the risk of shrinkage and cracking, making it more suitable for complex or uneven surfaces compared to the rigid nature of cement render.

Durability and Longevity Comparison

Acrylic render offers superior durability compared to cement render due to its flexible, crack-resistant properties and resistance to weathering, UV rays, and moisture. Cement render, while robust and strong, is prone to cracking and weakening over time, especially in harsh climates or areas with significant temperature fluctuations. The longevity of acrylic render often surpasses cement render, maintaining structural integrity and aesthetic appeal for 15 to 25 years with minimal maintenance, whereas cement render may require earlier repairs or replacement.

Aesthetic Finishes and Design Flexibility

Acrylic render offers a smooth, vibrant finish with superior color retention and flexibility, making it ideal for intricate textures and modern design aesthetics. Cement render provides a more traditional, robust surface with a coarser texture, suitable for classic or rustic building styles. The choice between acrylic and cement render significantly impacts the visual appeal and customization potential of exterior walls.

Cost Comparison: Acrylic Render vs Cement Render

Acrylic render typically costs between $30 to $50 per square meter, making it more expensive than cement render, which ranges from $15 to $25 per square meter. The higher initial cost of acrylic render is offset by its durability, flexibility, and lower maintenance requirements compared to cement render. Cement render may require more frequent repairs due to cracking and weather damage, ultimately affecting long-term expenses despite its lower upfront price.

Weather Resistance and Performance

Acrylic render offers superior weather resistance compared to cement render due to its flexibility and waterproof properties, which prevent cracking and water penetration. Cement render is more prone to shrinkage and can deteriorate under prolonged exposure to moisture and temperature fluctuations. Acrylic render's enhanced durability makes it ideal for harsh weather conditions, ensuring longer-lasting external wall protection.

Maintenance Requirements for Each Render

Acrylic render requires minimal maintenance due to its flexible, water-resistant properties that prevent cracking and reduce the need for frequent repairs. Cement render, while durable, demands regular upkeep such as sealing and patching to avoid water infiltration and surface degradation. Choosing acrylic render can significantly lower long-term maintenance costs compared to the more labor-intensive care of cement render.

Suitability for Various Substrates

Acrylic render offers superior flexibility and adhesion, making it ideal for diverse substrates such as brick, concrete, and fiber cement boards, where it compensates for slight substrate movements and cracks. Cement render, although more rigid and breathable, performs best on solid, porous surfaces like masonry and concrete blocks, providing robust protection but limited adaptability to substrate shifting. Selecting between acrylic and cement render depends heavily on the substrate type, environmental conditions, and desired longevity of the finish.

Environmental Impact of Acrylic and Cement Renders

Acrylic render produces lower carbon emissions during manufacturing compared to cement render, contributing to reduced environmental impact. Cement render relies on energy-intensive cement production, which generates significant greenhouse gases, making it less eco-friendly. Acrylic render's longer lifespan and flexibility reduce maintenance frequency, minimizing resource use and waste over time.

Acrylic Render vs Cement Render Infographic

productdif.com

productdif.com