Cast-in-place concrete is poured and cured directly at the construction site, allowing for custom shapes and seamless integration with foundation elements. Precast concrete is manufactured in controlled factory settings, offering superior quality control and faster installation times due to its modular nature. Selecting between these materials depends on project requirements, site conditions, and desired construction speed.

Table of Comparison

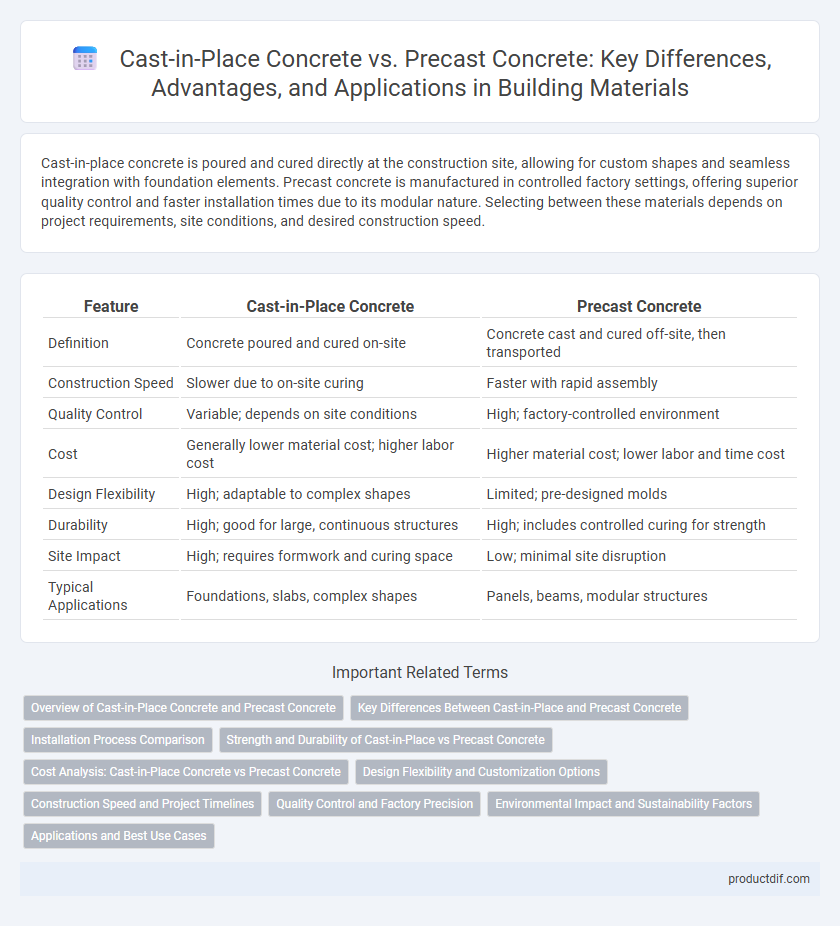

| Feature | Cast-in-Place Concrete | Precast Concrete |

|---|---|---|

| Definition | Concrete poured and cured on-site | Concrete cast and cured off-site, then transported |

| Construction Speed | Slower due to on-site curing | Faster with rapid assembly |

| Quality Control | Variable; depends on site conditions | High; factory-controlled environment |

| Cost | Generally lower material cost; higher labor cost | Higher material cost; lower labor and time cost |

| Design Flexibility | High; adaptable to complex shapes | Limited; pre-designed molds |

| Durability | High; good for large, continuous structures | High; includes controlled curing for strength |

| Site Impact | High; requires formwork and curing space | Low; minimal site disruption |

| Typical Applications | Foundations, slabs, complex shapes | Panels, beams, modular structures |

Overview of Cast-in-Place Concrete and Precast Concrete

Cast-in-place concrete is poured and cured directly at the construction site, offering flexibility in shaping and structural integration, ideal for custom designs and complex geometries. Precast concrete is manufactured in controlled factory environments, ensuring higher quality control, faster installation, and reduced site labor, commonly used for repetitive elements like panels, beams, and slabs. Both methods serve distinct roles in construction, with cast-in-place prioritizing onsite adaptability and precast emphasizing uniformity and efficiency.

Key Differences Between Cast-in-Place and Precast Concrete

Cast-in-place concrete is poured and cured directly at the construction site, offering flexibility for custom shapes and on-site adjustments, while precast concrete is manufactured in a controlled factory environment and transported to the site, ensuring consistent quality and faster installation. Cast-in-place requires formwork and longer curing times on-site, which can extend project timelines, whereas precast units reduce labor and minimize weather-related delays due to off-site production. The key differences impact project cost, construction speed, structural integrity, and design complexity, making each method suitable for specific building requirements.

Installation Process Comparison

Cast-in-place concrete requires onsite formwork, reinforcement placement, and curing, allowing for customization but extending installation time. Precast concrete is manufactured in controlled factory conditions, enabling faster onsite assembly and reduced labor costs due to standardized, pre-finished panels. The choice impacts project schedules, with precast concrete often accelerating installation for large-scale or repetitive structural elements.

Strength and Durability of Cast-in-Place vs Precast Concrete

Cast-in-place concrete offers superior structural continuity and strength due to its monolithic casting, reducing joints that can weaken the structure under stress. Precast concrete benefits from controlled manufacturing conditions, resulting in high-quality, dense, and durable components with enhanced resistance to weathering and chemical attack. Both methods provide robust durability, but cast-in-place concrete excels in customized, complex structural forms requiring integrally strong connections.

Cost Analysis: Cast-in-Place Concrete vs Precast Concrete

Cast-in-place concrete often incurs higher labor and formwork costs due to on-site pouring and curing, whereas precast concrete benefits from factory-controlled conditions that reduce waste and speed up installation. Precast concrete can lead to lower overall costs in large-scale projects by minimizing construction time and labor expenses, despite higher initial unit costs. The choice between cast-in-place and precast concrete depends largely on project size, complexity, and site accessibility, with precast offering cost advantages in repetitive or standardized components.

Design Flexibility and Customization Options

Cast-in-place concrete offers superior design flexibility, allowing for complex shapes, unique architectural details, and seamless integration with site conditions due to its onsite pouring process. Precast concrete provides customization through factory-controlled production, enabling consistent quality and precision in standard shapes but limits on-site adaptability. Project requirements, including structural complexity and aesthetic goals, typically guide the choice between cast-in-place and precast concrete for optimal design outcomes.

Construction Speed and Project Timelines

Cast-in-place concrete requires longer curing times on-site, potentially extending overall construction timelines, while precast concrete components are manufactured off-site simultaneously with site preparation, enabling faster assembly and reducing project duration. The use of precast concrete enhances construction speed by minimizing weather-related delays and on-site labor needs compared to cast-in-place methods. Leveraging precast elements can streamline scheduling and accelerate project delivery, especially in large-scale or time-sensitive construction projects.

Quality Control and Factory Precision

Cast-in-place concrete allows for flexible on-site adjustments but faces variability in quality control due to environmental factors and operator skill, impacting consistency. Precast concrete benefits from factory-controlled conditions, strict quality assurance protocols, and precision molds, ensuring uniformity and higher dimensional accuracy. The controlled environment of precasting significantly reduces defects and enhances durability compared to the variability inherent in cast-in-place methods.

Environmental Impact and Sustainability Factors

Cast-in-place concrete typically requires extensive on-site formwork and curing, leading to higher energy consumption and waste generation compared to precast concrete. Precast concrete elements are manufactured in controlled environments, allowing for optimized material usage, reduced waste, and less environmental disturbance during installation. Both methods offer opportunities for incorporating recycled materials and sustainable additives, but precast concrete generally provides a smaller carbon footprint due to efficient production and transportation logistics.

Applications and Best Use Cases

Cast-in-place concrete offers superior adaptability for complex architectural structures and on-site customizations, making it ideal for foundations, slabs, and large-scale infrastructure projects requiring monolithic strength. Precast concrete excels in repetitive elements such as beams, wall panels, and modular building components, enabling faster construction schedules and consistent quality through factory-controlled production. Best use cases depend on project scale, complexity, and timeline, with cast-in-place favored for unique designs and precast preferred for high-volume, uniform elements.

Cast-in-Place Concrete vs Precast Concrete Infographic

productdif.com

productdif.com