Rigid foam insulation offers superior thermal resistance and moisture control compared to fiberglass batts, making it ideal for areas prone to dampness or temperature fluctuations. Fiberglass batts are easier to install and more cost-effective, but they can lose effectiveness if compressed or poorly fitted. Choosing the right insulation depends on balancing performance needs with budget constraints for optimal building energy efficiency.

Table of Comparison

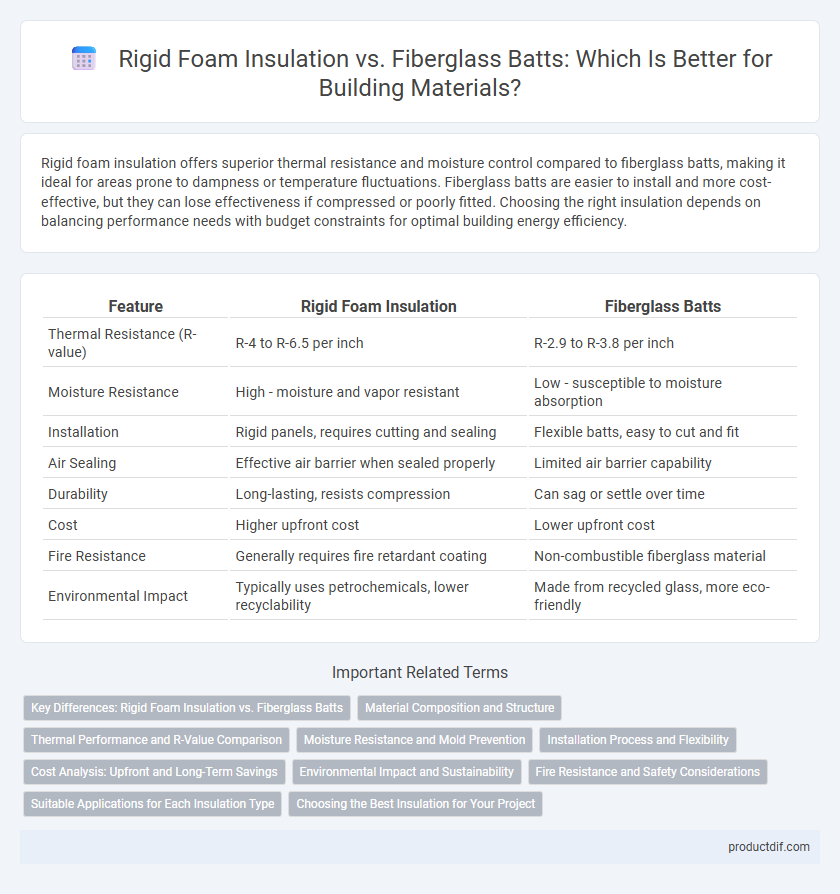

| Feature | Rigid Foam Insulation | Fiberglass Batts |

|---|---|---|

| Thermal Resistance (R-value) | R-4 to R-6.5 per inch | R-2.9 to R-3.8 per inch |

| Moisture Resistance | High - moisture and vapor resistant | Low - susceptible to moisture absorption |

| Installation | Rigid panels, requires cutting and sealing | Flexible batts, easy to cut and fit |

| Air Sealing | Effective air barrier when sealed properly | Limited air barrier capability |

| Durability | Long-lasting, resists compression | Can sag or settle over time |

| Cost | Higher upfront cost | Lower upfront cost |

| Fire Resistance | Generally requires fire retardant coating | Non-combustible fiberglass material |

| Environmental Impact | Typically uses petrochemicals, lower recyclability | Made from recycled glass, more eco-friendly |

Key Differences: Rigid Foam Insulation vs. Fiberglass Batts

Rigid foam insulation offers a higher R-value per inch compared to fiberglass batts, providing superior thermal resistance and energy efficiency. Unlike fiberglass batts, rigid foam panels are moisture-resistant and provide structural support while minimizing air leakage. Fiberglass batts are easier to install and more cost-effective but tend to lose effectiveness if compressed or exposed to moisture.

Material Composition and Structure

Rigid foam insulation consists of closed-cell polymers such as polyisocyanurate, extruded polystyrene (XPS), or expanded polystyrene (EPS), providing high thermal resistance and moisture resistance due to its dense, uniform structure. Fiberglass batts are made from fine glass fibers woven into flexible mats, which trap air pockets to reduce heat transfer but can allow moisture penetration if not properly installed. The solid, impermeable nature of rigid foam offers superior thermal performance and durability compared to the porous, fibrous composition of fiberglass batts.

Thermal Performance and R-Value Comparison

Rigid foam insulation offers higher R-values per inch, typically ranging from R-4 to R-6.5, compared to fiberglass batts which generally provide R-2.9 to R-3.8 per inch. This superior thermal performance of rigid foam enhances energy efficiency and minimizes heat transfer in building envelopes.

Moisture Resistance and Mold Prevention

Rigid foam insulation offers superior moisture resistance compared to fiberglass batts, reducing the risk of water absorption and mold growth within wall cavities. Its closed-cell structure acts as an effective barrier against humidity, maintaining insulation performance and structural integrity in damp environments. Fiberglass batts, while cost-effective, tend to retain moisture, increasing the likelihood of mold development and compromising indoor air quality.

Installation Process and Flexibility

Rigid foam insulation offers a straightforward installation process with large, pre-cut panels that fit tightly into wall cavities, reducing air gaps and improving thermal performance. Fiberglass batts require careful measurement and cutting to fit irregular spaces, demanding more skill and time to avoid compression and gaps. The flexibility of fiberglass allows it to conform to uneven surfaces, whereas rigid foam provides consistent thickness but lacks adaptability in complex framing.

Cost Analysis: Upfront and Long-Term Savings

Rigid foam insulation generally has a higher upfront cost compared to fiberglass batts but offers superior thermal resistance with R-values ranging from 4.5 to 6.5 per inch, resulting in greater long-term energy savings and reduced utility bills. Fiberglass batts, while less expensive initially, typically have lower R-values between 2.9 and 3.8 per inch and may require more frequent replacement or supplemental insulation to maintain effectiveness over time. Evaluating total lifecycle costs, including installation, energy savings, and maintenance, rigid foam insulation often provides better overall value for energy-efficient building projects.

Environmental Impact and Sustainability

Rigid foam insulation offers superior thermal resistance, reducing energy consumption and lowering greenhouse gas emissions over the building's lifecycle. Fiberglass batts, made from recycled glass, provide a more eco-friendly option with lower embodied energy but typically have lower R-values, requiring thicker installation to achieve comparable insulation performance. Choosing rigid foam or fiberglass batts depends on balancing energy efficiency, material recyclability, and overall carbon footprint to meet sustainability goals.

Fire Resistance and Safety Considerations

Rigid foam insulation offers superior fire resistance compared to fiberglass batts due to its closed-cell structure, which reduces flammability and limits smoke production during combustion. Fiberglass batts, while non-combustible, can lose insulating efficiency if exposed to fire, and their loose fibers may pose inhalation hazards when disturbed. Fire safety codes often require the use of specific fire barriers or coatings on rigid foam to enhance protection, making compliance crucial for safe installation.

Suitable Applications for Each Insulation Type

Rigid foam insulation is ideal for exterior walls, roofs, and foundation insulation due to its high R-value per inch and moisture resistance, providing excellent thermal performance in areas prone to water exposure. Fiberglass batts are best suited for interior walls, attics, and floors where ease of installation and cost-effectiveness are priorities, offering effective soundproofing and thermal insulation in dry conditions. Choosing the right insulation depends on the specific building application, climate, and moisture considerations to maximize energy efficiency and durability.

Choosing the Best Insulation for Your Project

Rigid foam insulation offers superior thermal resistance with R-values typically between 4.0 and 6.5 per inch, making it ideal for energy-efficient buildings. Fiberglass batts provide an economical option with R-values around 2.9 to 3.8 per inch and are easier to install in standard wall cavities. Selecting the best insulation depends on project requirements such as moisture resistance, ease of installation, budget constraints, and desired R-value for optimal thermal performance.

Rigid Foam Insulation vs Fiberglass Batts Infographic

productdif.com

productdif.com