AAC blocks offer superior thermal insulation and are lightweight, reducing overall construction costs compared to traditional red bricks. Red bricks provide excellent compressive strength and durability but require more skilled labor and longer curing times. Choosing between AAC blocks and red bricks depends on project requirements such as energy efficiency, load-bearing capacity, and budget constraints.

Table of Comparison

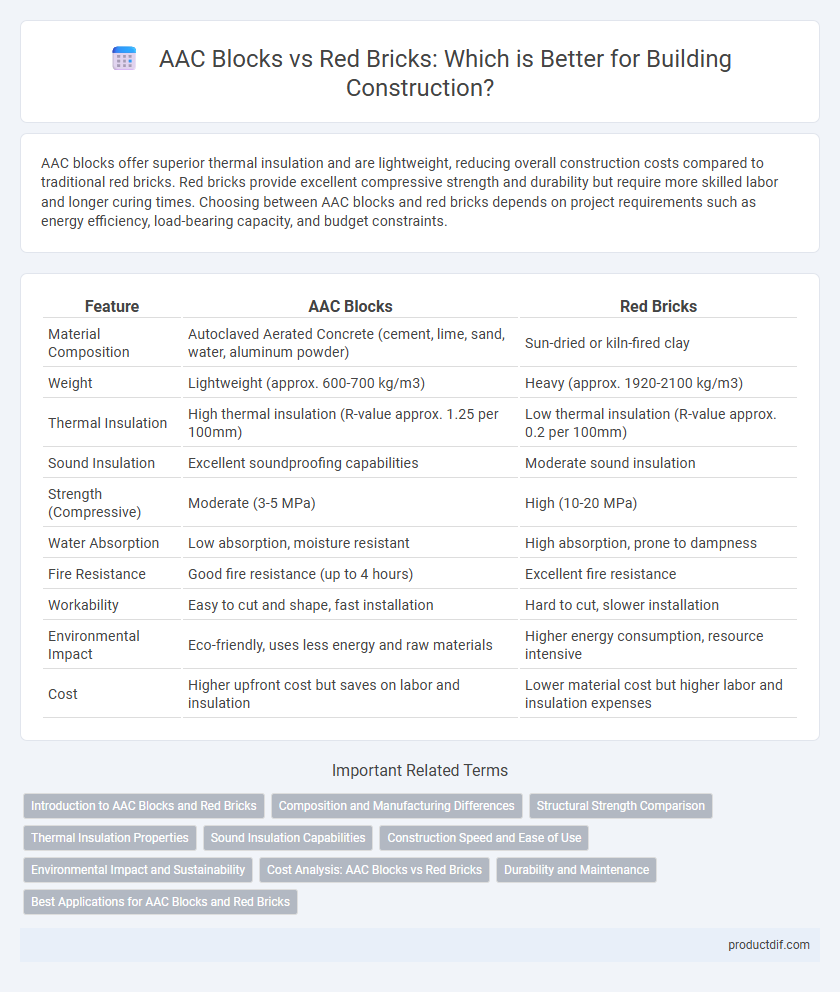

| Feature | AAC Blocks | Red Bricks |

|---|---|---|

| Material Composition | Autoclaved Aerated Concrete (cement, lime, sand, water, aluminum powder) | Sun-dried or kiln-fired clay |

| Weight | Lightweight (approx. 600-700 kg/m3) | Heavy (approx. 1920-2100 kg/m3) |

| Thermal Insulation | High thermal insulation (R-value approx. 1.25 per 100mm) | Low thermal insulation (R-value approx. 0.2 per 100mm) |

| Sound Insulation | Excellent soundproofing capabilities | Moderate sound insulation |

| Strength (Compressive) | Moderate (3-5 MPa) | High (10-20 MPa) |

| Water Absorption | Low absorption, moisture resistant | High absorption, prone to dampness |

| Fire Resistance | Good fire resistance (up to 4 hours) | Excellent fire resistance |

| Workability | Easy to cut and shape, fast installation | Hard to cut, slower installation |

| Environmental Impact | Eco-friendly, uses less energy and raw materials | Higher energy consumption, resource intensive |

| Cost | Higher upfront cost but saves on labor and insulation | Lower material cost but higher labor and insulation expenses |

Introduction to AAC Blocks and Red Bricks

AAC blocks, or Autoclaved Aerated Concrete blocks, are lightweight, precast building materials known for their excellent thermal insulation, fire resistance, and ease of installation, making them popular in modern construction. Red bricks, traditionally made from clay and fired at high temperatures, offer high compressive strength and durability, commonly used in load-bearing structures and masonry work. Comparing AAC blocks and red bricks highlights differences in weight, thermal performance, and environmental impact, influencing material choice in building projects.

Composition and Manufacturing Differences

AAC blocks are composed primarily of cement, lime, sand, water, and an aerating agent, creating a lightweight, porous structure through autoclaving. Red bricks are made from natural clay and shale, shaped and fired in kilns at high temperatures, resulting in a dense, heavy material. The manufacturing process of AAC blocks involves controlled chemical reactions and steam curing, while red bricks rely on traditional baking, influencing their strength, weight, and insulation properties.

Structural Strength Comparison

AAC blocks exhibit superior structural strength due to their lightweight yet high-compressive properties, typically ranging between 3.5 to 7 N/mm2, making them ideal for multi-story constructions. Red bricks have a compressive strength of approximately 3.5 N/mm2 but are heavier, which can increase the structural load and foundation requirements. The enhanced strength-to-weight ratio of AAC blocks offers better seismic resistance and energy efficiency compared to traditional red bricks.

Thermal Insulation Properties

AAC blocks provide superior thermal insulation compared to traditional red bricks due to their porous structure, which reduces heat transfer and maintains indoor temperature stability. The lightweight composition of AAC blocks enhances energy efficiency by minimizing the need for additional insulation materials. Red bricks, being denser and having higher thermal conductivity, result in greater heat retention and less effective temperature regulation within buildings.

Sound Insulation Capabilities

AAC blocks provide superior sound insulation compared to red bricks due to their porous structure and lightweight composition, which effectively absorbs and reduces noise transmission. The density and thickness of AAC blocks contribute to enhanced acoustic performance, making them ideal for residential and commercial constructions where noise control is critical. Red bricks, while durable, have a denser, less porous makeup that transmits sound more readily, resulting in lower soundproofing efficiency than AAC blocks.

Construction Speed and Ease of Use

AAC blocks offer significantly faster construction speed compared to red bricks due to their larger size and lightweight nature, which reduces the number of joints and eases handling. The uniform shape and precision of AAC blocks enhance ease of use and require less skilled labor, whereas red bricks demand more mortar and time for alignment. Consequently, AAC blocks streamline the building process, making them a preferred choice for projects with tight deadlines and labor constraints.

Environmental Impact and Sustainability

AAC blocks reduce environmental impact by consuming less raw material, generating lower carbon emissions, and offering superior thermal insulation that decreases energy use in buildings. Red bricks require high-temperature firing, leading to significant carbon dioxide emissions and depletion of clay resources, which impacts land degradation. Sustainable construction favors AAC blocks for their lightweight, recyclable nature and energy-efficient properties that support green building certifications.

Cost Analysis: AAC Blocks vs Red Bricks

AAC blocks offer a cost-efficient alternative to red bricks due to their lightweight nature, which reduces transportation and labor expenses by up to 30%. Although the initial material cost of AAC blocks may be slightly higher, savings in plastering and finishing lead to an overall 20-25% reduction in construction costs. Red bricks have lower raw material costs but incur higher labor and structural support expenses, making AAC blocks more economical for long-term projects.

Durability and Maintenance

AAC blocks offer superior durability compared to red bricks due to their high resistance to fire, moisture, and pests, which significantly reduces maintenance costs over time. Red bricks tend to absorb water and are prone to cracks and efflorescence, requiring frequent repairs and sealing to maintain structural integrity. The lightweight and uniformity of AAC blocks also contribute to less wear and tear, making them a more sustainable choice for long-term building maintenance.

Best Applications for AAC Blocks and Red Bricks

AAC blocks are best suited for constructing load-bearing walls, partition walls, and fire-resistant structures due to their lightweight, thermal insulation, and soundproofing properties. Red bricks are ideal for traditional masonry, foundations, and exterior walls where high compressive strength and durability are required. AAC blocks excel in modern, energy-efficient buildings, while red bricks support robust, long-lasting construction in diverse weather conditions.

AAC blocks vs Red bricks Infographic

productdif.com

productdif.com