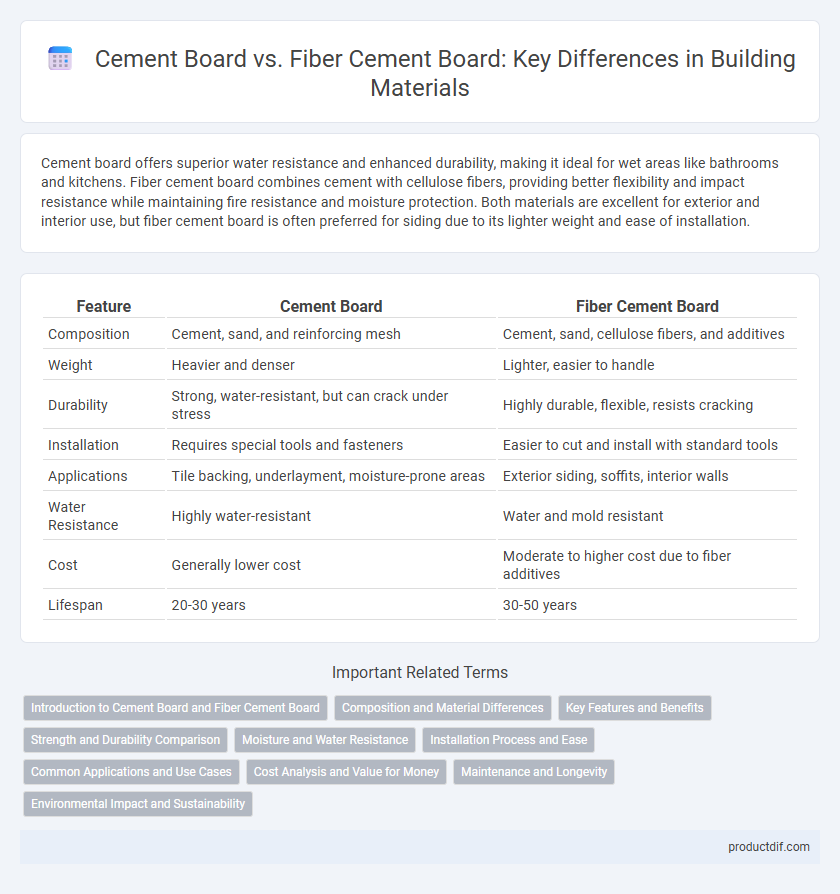

Cement board offers superior water resistance and enhanced durability, making it ideal for wet areas like bathrooms and kitchens. Fiber cement board combines cement with cellulose fibers, providing better flexibility and impact resistance while maintaining fire resistance and moisture protection. Both materials are excellent for exterior and interior use, but fiber cement board is often preferred for siding due to its lighter weight and ease of installation.

Table of Comparison

| Feature | Cement Board | Fiber Cement Board |

|---|---|---|

| Composition | Cement, sand, and reinforcing mesh | Cement, sand, cellulose fibers, and additives |

| Weight | Heavier and denser | Lighter, easier to handle |

| Durability | Strong, water-resistant, but can crack under stress | Highly durable, flexible, resists cracking |

| Installation | Requires special tools and fasteners | Easier to cut and install with standard tools |

| Applications | Tile backing, underlayment, moisture-prone areas | Exterior siding, soffits, interior walls |

| Water Resistance | Highly water-resistant | Water and mold resistant |

| Cost | Generally lower cost | Moderate to higher cost due to fiber additives |

| Lifespan | 20-30 years | 30-50 years |

Introduction to Cement Board and Fiber Cement Board

Cement board is a durable building material composed of cement and reinforcing fibers, commonly used as a backing for tile installations due to its moisture resistance and strength. Fiber cement board integrates cellulose fibers with cement, offering enhanced flexibility, impact resistance, and improved resistance to environmental factors like mold and rot. Both materials serve critical roles in construction, particularly in areas requiring moisture protection and structural stability.

Composition and Material Differences

Cement board consists primarily of a mixture of Portland cement and reinforcing fibers such as cellulose or fiberglass, providing high strength and water resistance. Fiber cement board incorporates a similar cement base but contains a higher ratio of cellulose fibers, resulting in improved flexibility and impact resistance. The variance in fiber content and composition directly influences durability, weight, and suitability for different construction applications.

Key Features and Benefits

Cement board offers exceptional moisture resistance and durability, making it ideal for wet areas like bathrooms and kitchens. Fiber cement board incorporates cellulose fibers for enhanced flexibility and impact resistance, improving overall strength and ease of installation. Both materials provide fire resistance, mold prevention, and long-lasting performance in exterior and interior applications.

Strength and Durability Comparison

Fiber cement board offers superior strength and durability compared to regular cement board due to its reinforced composition with cellulose fibers, which enhances impact resistance and flexibility. Cement board, while strong and moisture-resistant, is more brittle and prone to cracking under heavy load or stress. For applications requiring long-term structural integrity and resistance to environmental wear, fiber cement board provides a more reliable and durable solution.

Moisture and Water Resistance

Fiber cement boards provide superior moisture and water resistance compared to traditional cement boards due to their composite structure, which includes cellulose fibers that enhance durability and prevent water absorption. Cement boards, primarily made of cement and reinforcing fibers, offer good water resistance but can be more prone to water infiltration and swelling under prolonged exposure. Selecting fiber cement boards for exterior or high-moisture environments ensures long-lasting stability and reduced risk of mold or structural damage.

Installation Process and Ease

Fiber cement board offers easier installation compared to traditional cement board due to its lighter weight and enhanced flexibility, reducing handling difficulty and labor time. Cement board requires special tools for cutting and can be more brittle, leading to increased risk of cracking during installation. The ease of fiber cement board installation results in faster project completion and lower labor costs, making it a preferred choice for many construction professionals.

Common Applications and Use Cases

Cement board is widely used as a durable backing material for tile installations in wet areas such as bathrooms and kitchens, offering excellent water resistance and structural stability. Fiber cement board, containing cellulose fibers, is preferred for exterior siding, soffits, and fascia due to its enhanced flexibility, resistance to impacts, and improved aesthetic finishes. Both materials provide fire resistance and mold protection, but fiber cement boards excel in applications demanding a balance between weather durability and design versatility.

Cost Analysis and Value for Money

Cement board typically offers a lower upfront cost compared to fiber cement board, making it an attractive option for budget-conscious projects. Fiber cement board, while more expensive initially, provides superior durability, moisture resistance, and longer lifespan, resulting in better value for money over time. Investing in fiber cement board can reduce maintenance and replacement costs, offsetting the higher initial price through enhanced performance and longevity.

Maintenance and Longevity

Fiber cement boards offer superior resistance to moisture, mold, and termites compared to traditional cement boards, reducing maintenance needs over time. Their composition makes them less prone to cracking and warping, extending the lifespan of exterior cladding and interior walls. Regular cleaning and occasional sealing enhance durability, ensuring fiber cement boards maintain structural integrity and aesthetic appeal for decades.

Environmental Impact and Sustainability

Cement boards typically have a higher carbon footprint due to the energy-intensive production of Portland cement, whereas fiber cement boards incorporate cellulose fibers from sustainable wood sources, reducing environmental impact. Fiber cement boards also offer enhanced durability and resistance to moisture and mold, extending building lifespan and minimizing resource consumption over time. Choosing fiber cement boards supports sustainable construction practices by combining recycled materials with lower emissions, aligning with green building standards.

Cement Board vs Fiber Cement Board Infographic

productdif.com

productdif.com