Laminated glass consists of two or more glass layers bonded with an interlayer, offering enhanced safety by holding shards together when broken, making it ideal for windows requiring impact resistance and sound insulation. Tempered glass undergoes thermal or chemical treatment to increase strength and shatter into small, blunt pieces upon breakage, providing superior durability and safety in high-stress applications like doors and automotive windows. Choosing between laminated and tempered glass depends on specific building requirements for safety, soundproofing, and impact resistance.

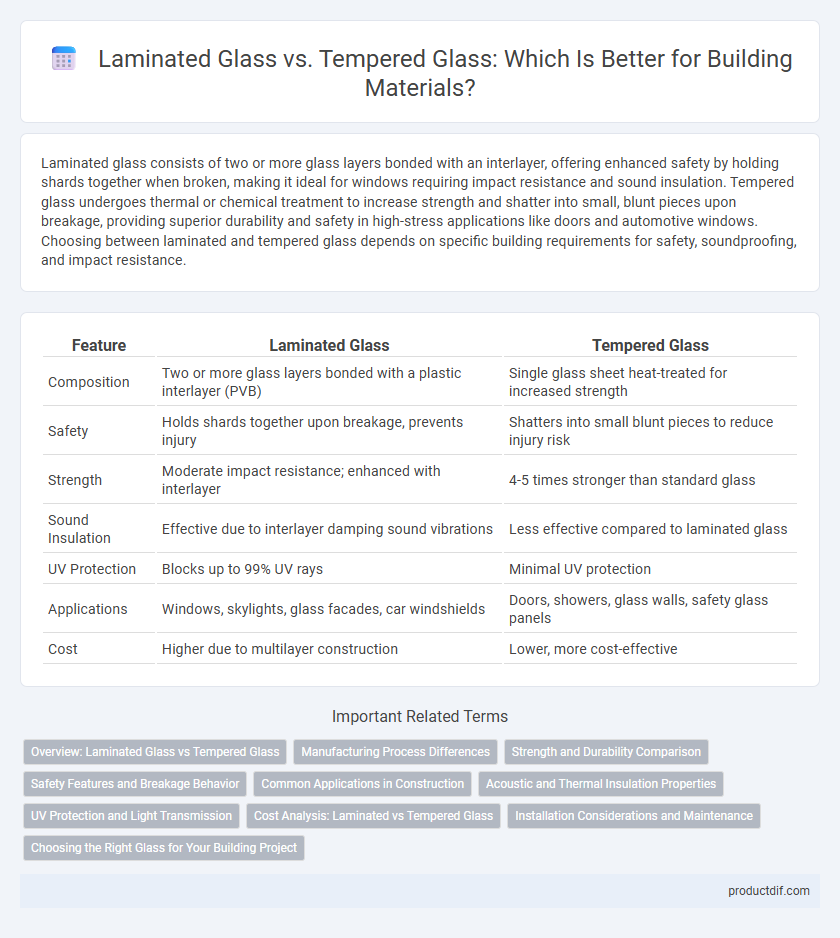

Table of Comparison

| Feature | Laminated Glass | Tempered Glass |

|---|---|---|

| Composition | Two or more glass layers bonded with a plastic interlayer (PVB) | Single glass sheet heat-treated for increased strength |

| Safety | Holds shards together upon breakage, prevents injury | Shatters into small blunt pieces to reduce injury risk |

| Strength | Moderate impact resistance; enhanced with interlayer | 4-5 times stronger than standard glass |

| Sound Insulation | Effective due to interlayer damping sound vibrations | Less effective compared to laminated glass |

| UV Protection | Blocks up to 99% UV rays | Minimal UV protection |

| Applications | Windows, skylights, glass facades, car windshields | Doors, showers, glass walls, safety glass panels |

| Cost | Higher due to multilayer construction | Lower, more cost-effective |

Overview: Laminated Glass vs Tempered Glass

Laminated glass consists of two or more glass layers bonded with an interlayer, offering enhanced safety by holding shards together upon impact. Tempered glass undergoes controlled thermal or chemical treatment to increase strength and shatter into small, blunt pieces for reduced injury risk. Both materials provide crucial safety features but differ in structural composition and impact behavior, affecting their applications in construction and automotive industries.

Manufacturing Process Differences

Laminated glass is produced by bonding two or more glass layers with an interlayer, usually polyvinyl butyral (PVB), through heat and pressure, creating a composite that holds together when shattered. Tempered glass undergoes a rapid heating and quenching process, which strengthens the glass by inducing compressive stress on its surfaces, enhancing its impact resistance. The key manufacturing difference lies in lamination's multi-layer assembly versus tempering's thermal treatment, affecting their performance and safety characteristics.

Strength and Durability Comparison

Laminated glass consists of two or more layers of glass bonded with an interlayer, providing enhanced strength and impact resistance by holding shards together upon breakage, making it highly durable for safety applications. Tempered glass is heat-treated to increase its strength up to four times that of standard glass, and it shatters into small, blunt pieces for safety, offering superior resistance to thermal stress and mechanical impact. While tempered glass excels in overall strength and durability under high stress, laminated glass offers better post-breakage integrity and sound insulation, making the choice dependent on specific structural and safety requirements.

Safety Features and Breakage Behavior

Laminated glass consists of two or more glass layers bonded with an interlayer, providing enhanced safety by holding shards in place when broken, reducing injury risk. Tempered glass undergoes a heat treatment process, increasing its strength and causing it to shatter into small, blunt granules that are less harmful upon impact. Both materials improve safety, with laminated glass offering better post-breakage integrity and tempered glass providing higher impact resistance.

Common Applications in Construction

Laminated glass is commonly used in skylights, facades, and windows requiring enhanced safety and sound insulation, while tempered glass is preferred for doors, partitions, and load-bearing glass components due to its high strength and shatter-resistance. Both materials meet essential building codes but serve distinct roles depending on safety requirements and structural needs. Laminated glass's ability to hold fragments together makes it ideal for impact-prone areas, whereas tempered glass is chosen for its durability under thermal and mechanical stress.

Acoustic and Thermal Insulation Properties

Laminated glass offers superior acoustic insulation due to its interlayer that dampens sound vibrations, making it ideal for noise reduction in urban environments. Tempered glass, while stronger and more resistant to impact, provides less effective thermal insulation compared to laminated glass. For enhanced energy efficiency and soundproofing in construction, laminated glass is the preferred choice over tempered glass.

UV Protection and Light Transmission

Laminated glass offers superior UV protection by blocking up to 99% of harmful ultraviolet rays, making it ideal for reducing interior fading and skin damage. Tempered glass provides high strength and safety through thermal treatment but allows more UV light to pass through, typically filtering only around 25% of UV radiation. Light transmission in laminated glass may be slightly lower due to the interlayer but generally maintains clarity, whereas tempered glass offers higher light transmission but less effective UV shielding.

Cost Analysis: Laminated vs Tempered Glass

Laminated glass typically costs more than tempered glass due to its complex manufacturing process involving multiple layers bonded with interlayers. Tempered glass offers a more affordable option with enhanced strength and safety, making it suitable for budget-conscious projects requiring durability. Cost differences vary depending on thickness, size, and specific safety requirements, impacting overall project budgets.

Installation Considerations and Maintenance

Laminated glass requires careful handling during installation to avoid delamination and often necessitates support along edges to maintain structural integrity. Tempered glass, due to its increased strength and shatter-resistant properties, allows for quicker installation with fewer edge supports, but demands precise cutting and tempering processes before installation. Maintenance for laminated glass involves checking the integrity of the interlayer for discoloration or separation, while tempered glass maintenance focuses on inspecting for surface chips or cracks that can compromise its safety features.

Choosing the Right Glass for Your Building Project

Laminated glass provides superior safety and sound insulation, making it ideal for windows and facades where impact resistance and noise reduction are priorities. Tempered glass offers enhanced strength and shatter resistance, suitable for structural applications like doors and partitions that require durability under stress. Selecting the right glass depends on the specific performance needs, such as safety standards, thermal insulation, and aesthetic preferences for your building project.

Laminated Glass vs Tempered Glass Infographic

productdif.com

productdif.com