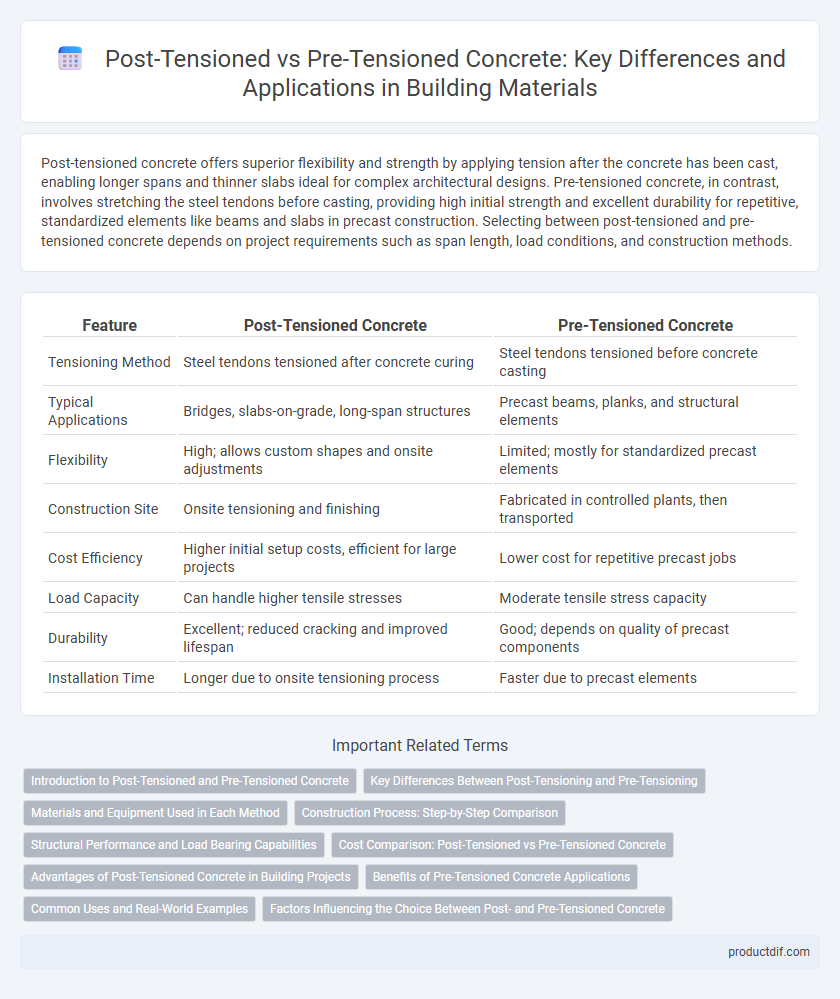

Post-tensioned concrete offers superior flexibility and strength by applying tension after the concrete has been cast, enabling longer spans and thinner slabs ideal for complex architectural designs. Pre-tensioned concrete, in contrast, involves stretching the steel tendons before casting, providing high initial strength and excellent durability for repetitive, standardized elements like beams and slabs in precast construction. Selecting between post-tensioned and pre-tensioned concrete depends on project requirements such as span length, load conditions, and construction methods.

Table of Comparison

| Feature | Post-Tensioned Concrete | Pre-Tensioned Concrete |

|---|---|---|

| Tensioning Method | Steel tendons tensioned after concrete curing | Steel tendons tensioned before concrete casting |

| Typical Applications | Bridges, slabs-on-grade, long-span structures | Precast beams, planks, and structural elements |

| Flexibility | High; allows custom shapes and onsite adjustments | Limited; mostly for standardized precast elements |

| Construction Site | Onsite tensioning and finishing | Fabricated in controlled plants, then transported |

| Cost Efficiency | Higher initial setup costs, efficient for large projects | Lower cost for repetitive precast jobs |

| Load Capacity | Can handle higher tensile stresses | Moderate tensile stress capacity |

| Durability | Excellent; reduced cracking and improved lifespan | Good; depends on quality of precast components |

| Installation Time | Longer due to onsite tensioning process | Faster due to precast elements |

Introduction to Post-Tensioned and Pre-Tensioned Concrete

Post-tensioned concrete involves casting concrete around ducts containing steel tendons, which are tensioned after the concrete has cured, creating compressive forces that enhance structural performance. Pre-tensioned concrete uses steel tendons tensioned before the concrete is poured, bonding the tendons to the concrete once it hardens, providing high strength and reduced cracking. Both methods improve concrete's tensile capacity, optimize material use, and enable the construction of longer spans in bridges, buildings, and slabs.

Key Differences Between Post-Tensioning and Pre-Tensioning

Post-tensioned concrete involves casting concrete around ducts containing steel tendons that are tensioned after the concrete has cured, enhancing load capacity and reducing structural thickness. Pre-tensioned concrete, by contrast, stretches the steel tendons before casting the concrete, creating immediate bond and high initial strength once the concrete hardens. Key differences include the stage of tensioning relative to casting, the method of force application, and suitability for onsite versus precast construction.

Materials and Equipment Used in Each Method

Post-tensioned concrete uses high-strength steel cables or tendons housed within plastic or metal ducts, tensioned after the concrete has cured, requiring hydraulic jacks and anchorage devices for tensioning. Pre-tensioned concrete involves high-tensile steel strands stretched between fixed abutments before concrete casting, necessitating strong pre-tensioning beds and stressing equipment. Both methods use high-quality Portland cement and aggregates, but post-tensioning requires additional sheathing materials to protect ducts and prevent corrosion.

Construction Process: Step-by-Step Comparison

Post-tensioned concrete involves casting concrete first and then tensioning the steel tendons within ducts after the concrete reaches a specific strength, allowing for more flexible design and longer spans. Pre-tensioned concrete requires tensioning steel tendons in a casting bed before placing concrete, ensuring high early strength and ideal for precast elements like beams and slabs. Post-tensioning incorporates grouting to protect steel, while pre-tensioning relies on bond strength between steel and hardened concrete without additional sealing.

Structural Performance and Load Bearing Capabilities

Post-tensioned concrete offers superior structural performance and enhanced load-bearing capabilities by applying tension after concrete curing, allowing longer spans and reduced slab thickness. Pre-tensioned concrete, tensioned before casting, provides consistent strength and is ideal for repetitive precast elements with high early strength requirements. Both methods improve durability and crack resistance, but post-tensioning is preferred for complex, heavy-load structures due to its adaptability and higher stress capacity.

Cost Comparison: Post-Tensioned vs Pre-Tensioned Concrete

Post-tensioned concrete generally offers cost savings over pre-tensioned concrete due to reduced material usage and lower transportation expenses since tendons are tensioned on-site. Pre-tensioned concrete requires specialized casting beds and more extensive handling, increasing initial production costs. Maintenance costs for post-tensioned systems can be higher over time, but initial construction efficiency often results in lower overall project expenditure.

Advantages of Post-Tensioned Concrete in Building Projects

Post-tensioned concrete offers enhanced structural strength by allowing longer spans and thinner slabs, reducing material usage and overall project costs. It provides superior crack control and durability under dynamic loads, making it ideal for bridges, parking structures, and high-rise buildings. The adaptability of post-tensioning systems enables faster construction times and greater design flexibility compared to pre-tensioned concrete.

Benefits of Pre-Tensioned Concrete Applications

Pre-tensioned concrete offers enhanced structural efficiency by allowing high-strength steel tendons to be tensioned before casting, resulting in superior load-bearing capacity and reduced cracking. This method improves durability and reduces construction time due to prefabrication in controlled environments, ensuring consistent quality. Applications in bridges, parking structures, and building floors benefit from pre-tensioned concrete's increased resistance to tensile stresses and economic material usage.

Common Uses and Real-World Examples

Post-tensioned concrete is commonly used in large-scale infrastructure projects such as bridges, parking structures, and high-rise buildings due to its ability to handle complex shapes and longer spans. Pre-tensioned concrete is frequently employed in manufacturing precast components like beams, slabs, and railway sleepers where uniform, repetitive elements are required. Examples of post-tensioned concrete include the Millau Viaduct in France, while pre-tensioned concrete is prominently used in modular highway barriers and parking lot panels.

Factors Influencing the Choice Between Post- and Pre-Tensioned Concrete

Selection between post-tensioned and pre-tensioned concrete depends on factors such as structural load requirements, span length, and construction site constraints. Post-tensioned concrete offers greater flexibility for longer spans and complex shapes, while pre-tensioned concrete provides higher production speed and quality control for standard, repetitive elements. Budget considerations, available equipment, and project timeline also significantly influence the decision-making process in concrete tensioning methods.

Post-tensioned concrete vs Pre-tensioned concrete Infographic

productdif.com

productdif.com