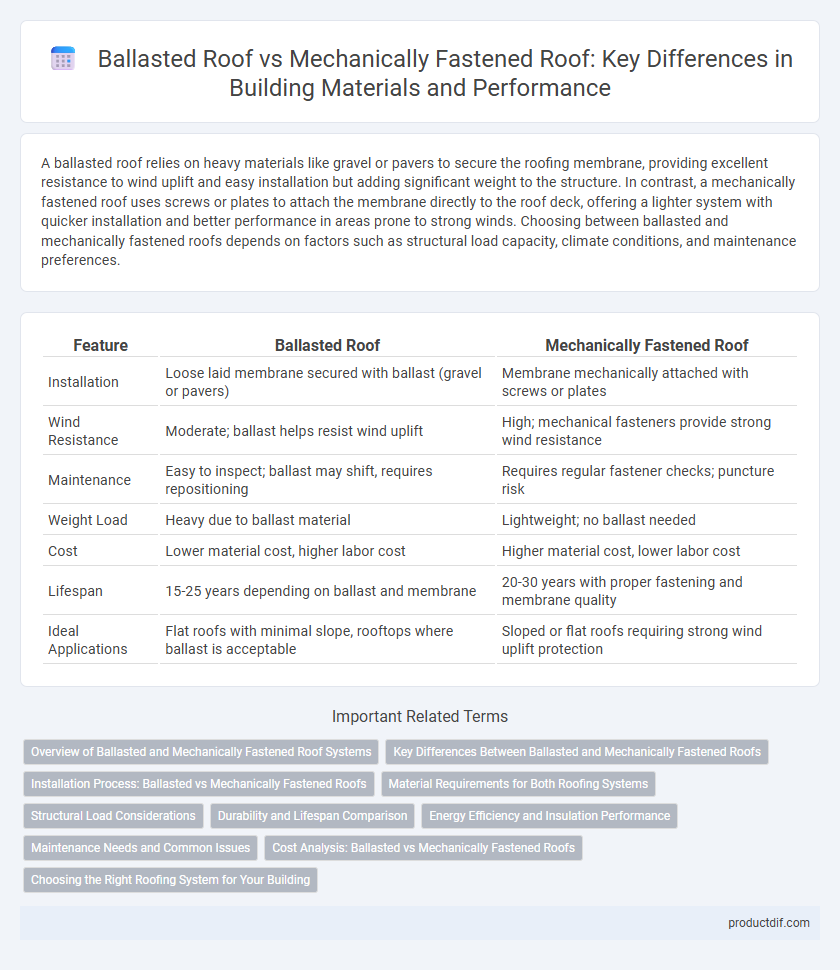

A ballasted roof relies on heavy materials like gravel or pavers to secure the roofing membrane, providing excellent resistance to wind uplift and easy installation but adding significant weight to the structure. In contrast, a mechanically fastened roof uses screws or plates to attach the membrane directly to the roof deck, offering a lighter system with quicker installation and better performance in areas prone to strong winds. Choosing between ballasted and mechanically fastened roofs depends on factors such as structural load capacity, climate conditions, and maintenance preferences.

Table of Comparison

| Feature | Ballasted Roof | Mechanically Fastened Roof |

|---|---|---|

| Installation | Loose laid membrane secured with ballast (gravel or pavers) | Membrane mechanically attached with screws or plates |

| Wind Resistance | Moderate; ballast helps resist wind uplift | High; mechanical fasteners provide strong wind resistance |

| Maintenance | Easy to inspect; ballast may shift, requires repositioning | Requires regular fastener checks; puncture risk |

| Weight Load | Heavy due to ballast material | Lightweight; no ballast needed |

| Cost | Lower material cost, higher labor cost | Higher material cost, lower labor cost |

| Lifespan | 15-25 years depending on ballast and membrane | 20-30 years with proper fastening and membrane quality |

| Ideal Applications | Flat roofs with minimal slope, rooftops where ballast is acceptable | Sloped or flat roofs requiring strong wind uplift protection |

Overview of Ballasted and Mechanically Fastened Roof Systems

Ballasted roof systems utilize heavy materials such as gravel or pavers to secure the roofing membrane, providing enhanced protection against wind uplift and UV exposure. Mechanically fastened roof systems rely on screws, plates, or other fasteners to attach the membrane directly to the roof deck, offering easier installation and adaptability for various roof shapes. Both systems are popular in commercial roofing, with ballasted roofs favored for flat or low-slope applications and mechanically fastened roofs chosen for their cost-effectiveness and durability on larger structures.

Key Differences Between Ballasted and Mechanically Fastened Roofs

Ballasted roofs rely on heavy materials such as gravel or pavers to hold the roofing membrane in place, providing excellent resistance to wind uplift without needing mechanical fasteners, making them ideal for flat or low-slope buildings. Mechanically fastened roofs use screws, plates, or nails to secure the membrane directly to the roof deck, offering quicker installation and suitability for various building types but may be more susceptible to wind damage without proper fastening techniques. The choice between ballasted and mechanically fastened roofing systems depends on factors like roof slope, building structure, wind load requirements, and maintenance considerations.

Installation Process: Ballasted vs Mechanically Fastened Roofs

Ballasted roofs involve placing heavy materials such as gravel or pavers over a loose-laid membrane to secure it, requiring minimal penetrations and faster installation on flat surfaces. Mechanically fastened roofs use screws, plates, or fasteners to attach membranes directly to the roof deck, offering greater wind uplift resistance but demanding precise alignment and more labor. Installation time for ballasted systems is generally shorter, while mechanically fastened systems require careful fastening and membrane overlap to ensure durability.

Material Requirements for Both Roofing Systems

Ballasted roofs require heavy, dense materials such as gravel or pavers to secure the membrane against wind uplift, while mechanically fastened roofs rely on fasteners, plates, and membrane sheets designed to withstand mechanical attachment stress. The membrane in ballasted systems is typically robust and flexible to accommodate settling stones, whereas mechanically fastened membranes must exhibit high tensile strength and resistance to punctures from fasteners. Insulation boards for both systems must be compatible with their respective fastening methods, ensuring thermal performance without compromising roof integrity.

Structural Load Considerations

Ballasted roofs distribute structural loads through a layer of gravel or pavers, which adds significant weight and requires the underlying structure to support increased dead loads. Mechanically fastened roofs rely on fasteners attached directly to the roof deck, resulting in a lighter overall system that minimizes additional load on the building framework. Evaluating structural load capacity and building design is critical when selecting between ballasted and mechanically fastened roofing systems to ensure safety and performance compliance.

Durability and Lifespan Comparison

Ballasted roofs offer enhanced durability with a heavy layer of ballast that protects the membrane from UV damage and mechanical wear, often extending their lifespan up to 30 years. Mechanically fastened roofs provide strong resistance to wind uplift through secure fastening methods, but they may experience membrane punctures and faster degradation, resulting in a typical lifespan of 15 to 20 years. Choosing between these systems depends on environmental factors and maintenance capabilities, with ballasted roofs generally outperforming in durability under harsh conditions.

Energy Efficiency and Insulation Performance

Ballasted roofs provide superior thermal insulation by adding a layer of gravel or heavy material that helps maintain consistent roof temperature and reduce heat loss. Mechanically fastened roofs often have less insulation capacity due to exposed fasteners that can create thermal bridging, lowering overall energy efficiency. Selecting ballasted roofing systems enhances building energy performance by minimizing heat transfer and improving insulation durability.

Maintenance Needs and Common Issues

Ballasted roofs require regular inspection to ensure ballast integrity and prevent stone displacement, which can cause membrane damage and water infiltration. Mechanically fastened roofs often face issues with fastener corrosion and membrane punctures, necessitating routine checks and timely repairs to maintain system performance. Both roofing types benefit from scheduled maintenance to address wear, UV damage, and potential leaks, but ballasted roofs generally demand more frequent ballast management.

Cost Analysis: Ballasted vs Mechanically Fastened Roofs

Ballasted roofs typically offer lower initial installation costs due to simpler materials and labor requirements, whereas mechanically fastened roofs incur higher upfront expenses owing to specialized equipment and fasteners. Over time, ballasted roofs may require more maintenance to manage ballast displacement, potentially increasing lifecycle costs compared to mechanically fastened systems known for easier inspections and repairs. Cost analysis should consider total cost of ownership, including installation, maintenance, and potential energy savings from each roofing type.

Choosing the Right Roofing System for Your Building

Selecting the right roofing system for your building depends on factors like climate, building structure, and maintenance requirements. Ballasted roofs offer excellent protection against wind uplift by using heavy ballast such as gravel, making them ideal for flat or low-slope roofs with minimal penetrations. Mechanically fastened roofs provide strong attachment through screws or plates, offering better performance in areas with extreme weather conditions and on buildings requiring frequent roof access or modifications.

Ballasted Roof vs Mechanically Fastened Roof Infographic

productdif.com

productdif.com