Shiplap and tongue and groove are popular building materials known for their interlocking designs that enhance structural integrity and weather resistance. Shiplap features overlapping boards with a rabbet joint, creating a distinctive shadow line ideal for rustic or coastal aesthetics. Tongue and groove panels fit snugly with a tongue on one board fitting into a groove on the adjacent board, offering a seamless, tight finish favored for flooring, ceilings, and walls.

Table of Comparison

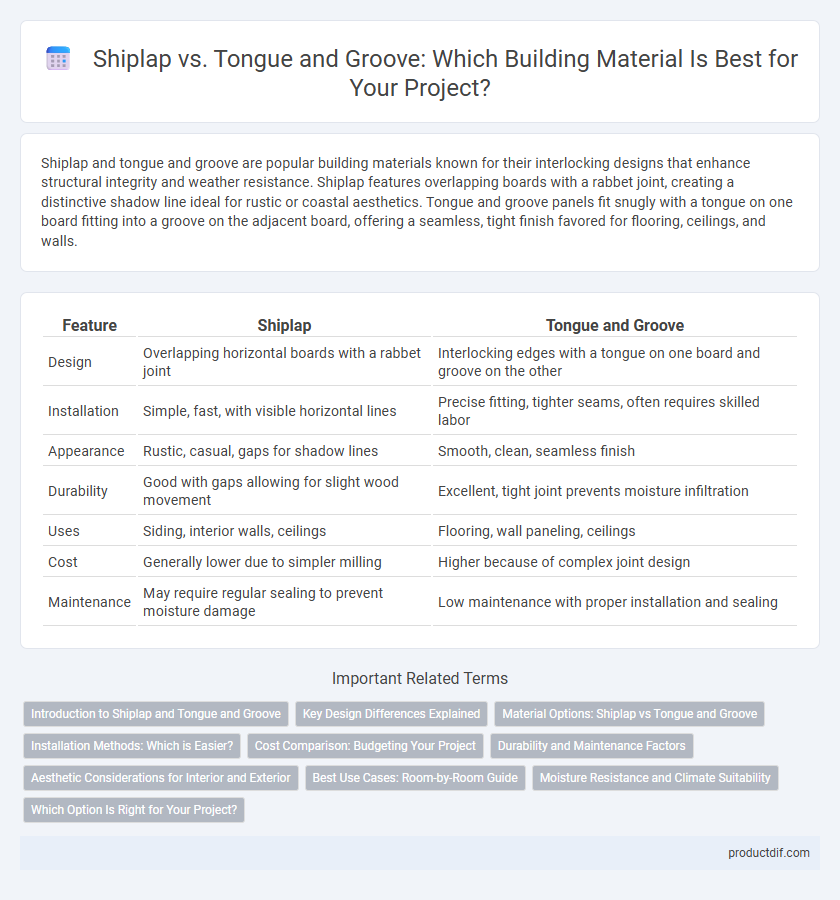

| Feature | Shiplap | Tongue and Groove |

|---|---|---|

| Design | Overlapping horizontal boards with a rabbet joint | Interlocking edges with a tongue on one board and groove on the other |

| Installation | Simple, fast, with visible horizontal lines | Precise fitting, tighter seams, often requires skilled labor |

| Appearance | Rustic, casual, gaps for shadow lines | Smooth, clean, seamless finish |

| Durability | Good with gaps allowing for slight wood movement | Excellent, tight joint prevents moisture infiltration |

| Uses | Siding, interior walls, ceilings | Flooring, wall paneling, ceilings |

| Cost | Generally lower due to simpler milling | Higher because of complex joint design |

| Maintenance | May require regular sealing to prevent moisture damage | Low maintenance with proper installation and sealing |

Introduction to Shiplap and Tongue and Groove

Shiplap and tongue and groove are popular building materials used for wall paneling and exterior siding, valued for their durability and aesthetic appeal. Shiplap features horizontal wooden boards with rabbeted edges that create a tight, overlapping seal, promoting weather resistance and a distinctive shadow line. Tongue and groove panels interlock with a protruding tongue fitting into a corresponding groove, ensuring a seamless and sturdy surface ideal for both floors and walls.

Key Design Differences Explained

Shiplap features rabbeted edges that create a distinctive shadow line and allow for slight expansion and contraction, making it ideal for exterior siding and rustic interior walls. Tongue and groove boards interlock with a protruding tongue on one board fitting into a corresponding groove on the next, providing a tighter, more seamless fit preferred for flooring and interior paneling. The key design difference lies in shiplap's overlapping edge for weather resistance versus tongue and groove's flush joint for structural stability and smooth surface finish.

Material Options: Shiplap vs Tongue and Groove

Shiplap and tongue and groove both offer diverse material options, including pine, cedar, and composite wood, which affect durability and aesthetic appeal. Shiplap boards feature a rabbeted edge that allows easy overlapping, making softwoods like pine ideal for cost-effective siding and interior walls. Tongue and groove joints provide a tighter seal and enhanced stability, often used with hardwoods such as oak or engineered wood for flooring and cabinetry applications.

Installation Methods: Which is Easier?

Shiplap boards feature simple rabbeted edges that allow them to easily overlap, making installation faster and requiring fewer precise cuts compared to tongue and groove boards that interlock tightly with a groove and a matching tongue, demanding more skill and accurate alignment. Shiplap can be nailed directly to the surface without specialized tools, whereas tongue and groove installation often needs additional equipment like a flooring nailer and careful joint fitting to ensure a seamless finish. For DIY projects and quick wall paneling, shiplap is generally easier to install, while tongue and groove provides a stronger, more stable connection suited for flooring and high-traffic areas.

Cost Comparison: Budgeting Your Project

Shiplap boards typically cost less per linear foot compared to tongue and groove due to their simpler profile and easier installation, reducing labor expenses. Tongue and groove materials offer a tighter fit and increased durability, which can increase upfront costs but may lower long-term maintenance expenses. Budgeting your project requires balancing initial material costs with installation complexity and desired finish quality to optimize overall value.

Durability and Maintenance Factors

Shiplap boards feature overlapping edges that create a tight seal, making them highly resistant to moisture and less prone to warping, which enhances long-term durability in exterior applications. Tongue and groove joints interlock more securely, providing a strong structural bond that reduces gaps and enhances stability but may require more maintenance to prevent dirt accumulation in the grooves. Both materials benefit from proper sealing and periodic maintenance, but shiplap generally demands less upkeep due to its simpler design and superior weather resistance.

Aesthetic Considerations for Interior and Exterior

Shiplap features a clean, flat profile with a distinctive shadow line that enhances modern and rustic aesthetics for both interior walls and exterior siding. Tongue and groove offers a tightly interlocking design that creates a seamless, smooth surface ideal for traditional, craftsman, and cottage-style interiors or exteriors. Both materials provide weather-resistant qualities, but tongue and groove typically delivers a more refined, polished appearance while shiplap emphasizes texture and depth.

Best Use Cases: Room-by-Room Guide

Shiplap is ideal for creating rustic or farmhouse-style walls in living rooms and bedrooms due to its simple overlapping design that allows for expansion and contraction; it is also suitable for exterior siding because of its weather-resistant properties. Tongue and groove panels, with their tight interlocking edges, provide a seamless finish perfect for ceilings and flooring in spaces like kitchens and bathrooms where moisture resistance and stability are crucial. Using shiplap in accent walls and tongue and groove for structural applications enhances both aesthetic appeal and functional durability room by room.

Moisture Resistance and Climate Suitability

Shiplap offers superior moisture resistance due to its overlapping design that prevents water infiltration, making it ideal for humid or rainy climates. Tongue and groove joints create a tight, interlocking seal but can be more susceptible to moisture damage if not properly sealed or maintained, limiting their effectiveness in extremely wet environments. Both materials perform well in temperate climates, but shiplap's enhanced water-shedding capability provides greater durability in areas with high humidity or frequent precipitation.

Which Option Is Right for Your Project?

Shiplap offers a clean, overlapping design ideal for rustic or farmhouse aesthetics, providing excellent weather resistance and easy installation for exterior or interior walls. Tongue and groove boards fit tightly together with interlocking edges, creating a smooth, seamless appearance perfect for flooring, ceilings, or paneling that requires structural stability. Choosing between shiplap and tongue and groove depends on your project's requirements for durability, visual style, and installation complexity.

Shiplap vs Tongue and Groove Infographic

productdif.com

productdif.com