PVC and CPVC are both durable building materials used for piping systems, but they differ in temperature resistance and chemical compatibility. PVC is suitable for cold water applications and drainage systems, while CPVC handles higher temperatures and is ideal for hot water supply lines. Choosing between PVC and CPVC depends on the specific temperature requirements and environmental conditions of the project.

Table of Comparison

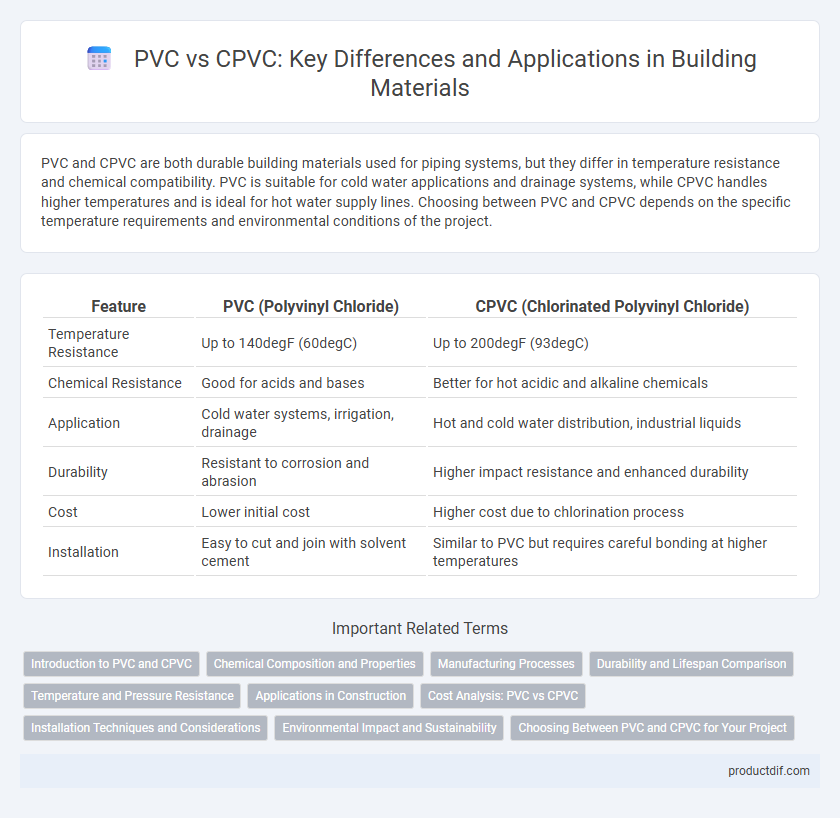

| Feature | PVC (Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) |

|---|---|---|

| Temperature Resistance | Up to 140degF (60degC) | Up to 200degF (93degC) |

| Chemical Resistance | Good for acids and bases | Better for hot acidic and alkaline chemicals |

| Application | Cold water systems, irrigation, drainage | Hot and cold water distribution, industrial liquids |

| Durability | Resistant to corrosion and abrasion | Higher impact resistance and enhanced durability |

| Cost | Lower initial cost | Higher cost due to chlorination process |

| Installation | Easy to cut and join with solvent cement | Similar to PVC but requires careful bonding at higher temperatures |

Introduction to PVC and CPVC

PVC (Polyvinyl Chloride) is a versatile plastic widely used in building materials for its durability, affordability, and resistance to corrosion, commonly applied in pipes, fittings, and window frames. CPVC (Chlorinated Polyvinyl Chloride) is a chlorinated variant of PVC that offers enhanced temperature and chemical resistance, making it suitable for hot water supply and industrial applications. Both materials provide strong structural integrity and ease of installation but differ primarily in temperature tolerance and chemical durability.

Chemical Composition and Properties

PVC (Polyvinyl Chloride) consists mainly of vinyl chloride monomers, exhibiting strong chemical resistance to acids, alkalis, and salts, making it ideal for cold water and drainage applications. CPVC (Chlorinated Polyvinyl Chloride) is produced by chlorinating PVC, which increases its chlorine content and enhances thermal stability and chemical resistance, allowing it to withstand higher temperatures and more aggressive chemicals. The higher chlorine content in CPVC results in improved durability and fire resistance compared to standard PVC, making it suitable for hot water and industrial fluid systems.

Manufacturing Processes

PVC and CPVC are produced through polymerization processes involving vinyl chloride monomers, with CPVC undergoing an additional chlorination step that increases its chlorine content and enhances heat resistance. The manufacturing of CPVC requires precise temperature and chemical controls to ensure the stability and performance of the polymer for high-temperature applications. Both materials are extruded or molded into pipes and fittings, but CPVC's specialized production techniques result in increased durability and chemical resistance compared to standard PVC.

Durability and Lifespan Comparison

PVC offers excellent durability with resistance to corrosion, chemicals, and impact, making it suitable for cold water applications, while CPVC provides enhanced thermal resistance and can withstand higher temperatures up to 200degF, extending its lifespan in hot water systems. CPVC's improved heat tolerance results in less degradation and longer service life compared to PVC when exposed to elevated temperatures. Both materials exhibit strong structural integrity, but CPVC is preferable for durability in demanding, high-temperature environments.

Temperature and Pressure Resistance

PVC (Polyvinyl Chloride) typically withstands temperatures up to 140degF (60degC) and pressures suitable for low to moderate plumbing applications, while CPVC (Chlorinated Polyvinyl Chloride) offers enhanced thermal resistance up to 200degF (93degC), making it ideal for hot water systems. CPVC also maintains structural integrity under higher pressure conditions, commonly rated for pressures up to 150 psi at elevated temperatures, surpassing standard PVC performance. This superior temperature and pressure resistance of CPVC makes it the preferred material for industrial and residential hot water piping systems.

Applications in Construction

PVC is commonly used for cold water pipes, irrigation, and drainage systems due to its durability and cost-effectiveness. CPVC is preferred for hot water distribution and industrial liquid handling because of its higher temperature resistance and chemical stability. In construction, selecting between PVC and CPVC depends on specific project requirements including temperature tolerance and exposure to corrosive substances.

Cost Analysis: PVC vs CPVC

PVC pipes generally offer a lower initial cost compared to CPVC, making them more budget-friendly for large-scale construction projects. CPVC, while more expensive upfront, provides better chemical resistance and higher temperature tolerance, which can reduce long-term maintenance and replacement costs. Evaluating total lifecycle expenses reveals that CPVC's durability may lead to overall savings despite its higher initial price point.

Installation Techniques and Considerations

PVC pipes require solvent cementing with primer and cleaner to ensure strong, leak-free joints, while CPVC installation demands careful temperature considerations due to its ability to handle higher heat. CPVC connections often involve specialized adhesives compatible with its chlorinated composition, and installers must allow proper curing time to prevent joint failures. Both materials benefit from precise cutting and deburring, but CPVC's brittleness at lower temperatures necessitates careful handling during assembly.

Environmental Impact and Sustainability

PVC and CPVC differ significantly in environmental impact and sustainability; PVC production releases more dioxins and toxic chemicals, contributing to air and water pollution, whereas CPVC manufacturing involves fewer harmful emissions and improved thermal resistance, enhancing its lifespan. Both materials are recyclable, but CPVC's higher durability reduces replacement frequency, minimizing resource consumption and waste generation over time. Selecting CPVC over PVC supports sustainable building practices by lowering carbon footprint and promoting longer-lasting infrastructure materials.

Choosing Between PVC and CPVC for Your Project

PVC offers excellent chemical resistance and affordability, making it ideal for cold water plumbing, irrigation, and drainage systems. CPVC withstands higher temperatures up to 200degF, suitable for hot water lines and industrial applications requiring durability and heat resistance. Selecting between PVC and CPVC depends on project temperature requirements, budget constraints, and chemical exposure considerations.

PVC vs CPVC Infographic

productdif.com

productdif.com