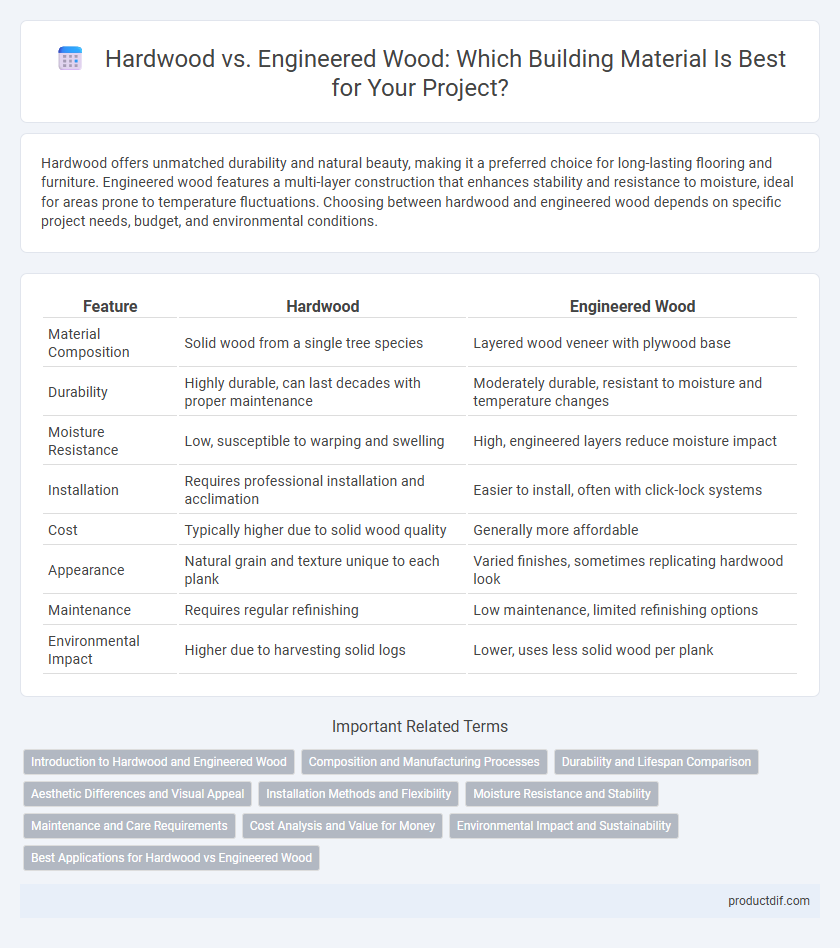

Hardwood offers unmatched durability and natural beauty, making it a preferred choice for long-lasting flooring and furniture. Engineered wood features a multi-layer construction that enhances stability and resistance to moisture, ideal for areas prone to temperature fluctuations. Choosing between hardwood and engineered wood depends on specific project needs, budget, and environmental conditions.

Table of Comparison

| Feature | Hardwood | Engineered Wood |

|---|---|---|

| Material Composition | Solid wood from a single tree species | Layered wood veneer with plywood base |

| Durability | Highly durable, can last decades with proper maintenance | Moderately durable, resistant to moisture and temperature changes |

| Moisture Resistance | Low, susceptible to warping and swelling | High, engineered layers reduce moisture impact |

| Installation | Requires professional installation and acclimation | Easier to install, often with click-lock systems |

| Cost | Typically higher due to solid wood quality | Generally more affordable |

| Appearance | Natural grain and texture unique to each plank | Varied finishes, sometimes replicating hardwood look |

| Maintenance | Requires regular refinishing | Low maintenance, limited refinishing options |

| Environmental Impact | Higher due to harvesting solid logs | Lower, uses less solid wood per plank |

Introduction to Hardwood and Engineered Wood

Hardwood is a natural solid wood derived from deciduous trees like oak, maple, and cherry, known for its durability, aesthetic grain patterns, and long lifespan in construction and flooring. Engineered wood consists of multiple layers of wood veneers or fibers bonded together, designed to enhance stability and resist moisture compared to solid hardwood. Both materials offer unique benefits in building, with hardwood prized for natural beauty and engineered wood favored for dimensional stability.

Composition and Manufacturing Processes

Hardwood is made from solid wood cut directly from trees, maintaining natural grain patterns and density, which provides durability and a classic aesthetic. Engineered wood consists of multiple layers, including a top layer of hardwood veneer glued over a core of plywood or high-density fiberboard, offering enhanced stability and resistance to moisture and temperature changes. The manufacturing process for engineered wood involves pressing and bonding these layers under heat and pressure, resulting in a product that reduces warping and expands design flexibility compared to traditional hardwood.

Durability and Lifespan Comparison

Hardwood offers superior durability and a longer lifespan due to its dense, solid structure, often lasting over 50 years with proper care. Engineered wood combines layers of plywood with a hardwood veneer, providing enhanced resistance to moisture and temperature fluctuations but typically has a shorter lifespan of 20 to 30 years. Both materials are durable, but hardwood is generally preferred for long-term applications where maximum longevity is essential.

Aesthetic Differences and Visual Appeal

Hardwood offers a rich, natural grain pattern and authentic texture that enhances visual warmth and character in interior spaces. Engineered wood features a consistent surface veneer that can mimic various wood species while providing uniformity and resistance to warping. The choice between hardwood and engineered wood often depends on desired aesthetic complexity versus practical design flexibility.

Installation Methods and Flexibility

Hardwood flooring typically requires nailing or stapling to a wooden subfloor, limiting installation to specific subfloor types and making it less adaptable for below-grade levels. Engineered wood offers greater flexibility with multiple installation methods including glue-down, floating, or stapling, allowing use over concrete slabs, radiant heating systems, and uneven subfloors. This versatility makes engineered wood a preferred choice for diverse environments and DIY installations.

Moisture Resistance and Stability

Hardwood offers natural durability but is more susceptible to moisture fluctuations, causing potential warping or swelling. Engineered wood features a layered construction with moisture-resistant adhesives, enhancing dimensional stability even in humid environments. This makes engineered wood a preferred choice for areas with variable moisture levels, while hardwood suits controlled indoor settings.

Maintenance and Care Requirements

Hardwood flooring requires regular sweeping, occasional refinishing, and protection from moisture to maintain its durability and appearance. Engineered wood demands less maintenance, as its layered construction offers better resistance to humidity and temperature changes, reducing the need for frequent refinishing. Both materials benefit from using appropriate cleaning products and avoiding excessive water to prolong their lifespan.

Cost Analysis and Value for Money

Hardwood flooring typically costs between $8 and $15 per square foot, offering long-term durability and the potential for refinishing, which can enhance its lifespan and value. Engineered wood ranges from $4 to $10 per square foot, providing a cost-effective alternative with easier installation and resistance to moisture but limited refinishing options. Evaluating cost vs. value, hardwood offers greater longevity and resale appeal, while engineered wood delivers budget-friendly performance and adaptability for various environments.

Environmental Impact and Sustainability

Hardwood is a natural, renewable resource that sequesters carbon and typically has a longer lifespan, reducing the need for frequent replacement and minimizing waste. Engineered wood uses wood fibers and adhesives to maximize material efficiency, often sourced from fast-growing, sustainably managed forests, which lowers deforestation pressure. Life cycle assessments show engineered wood generally has a smaller carbon footprint due to its optimized resource use and reduced reliance on old-growth timber.

Best Applications for Hardwood vs Engineered Wood

Hardwood is ideal for high-traffic areas like living rooms and hallways due to its durability and ability to be refinished multiple times. Engineered wood performs best in moisture-prone spaces such as basements and kitchens because its layered construction offers enhanced stability against humidity. Choosing between hardwood and engineered wood depends on the environmental conditions and intended use, with hardwood favored for longevity and engineered wood preferred for resistance to moisture.

Hardwood vs Engineered Wood Infographic

productdif.com

productdif.com