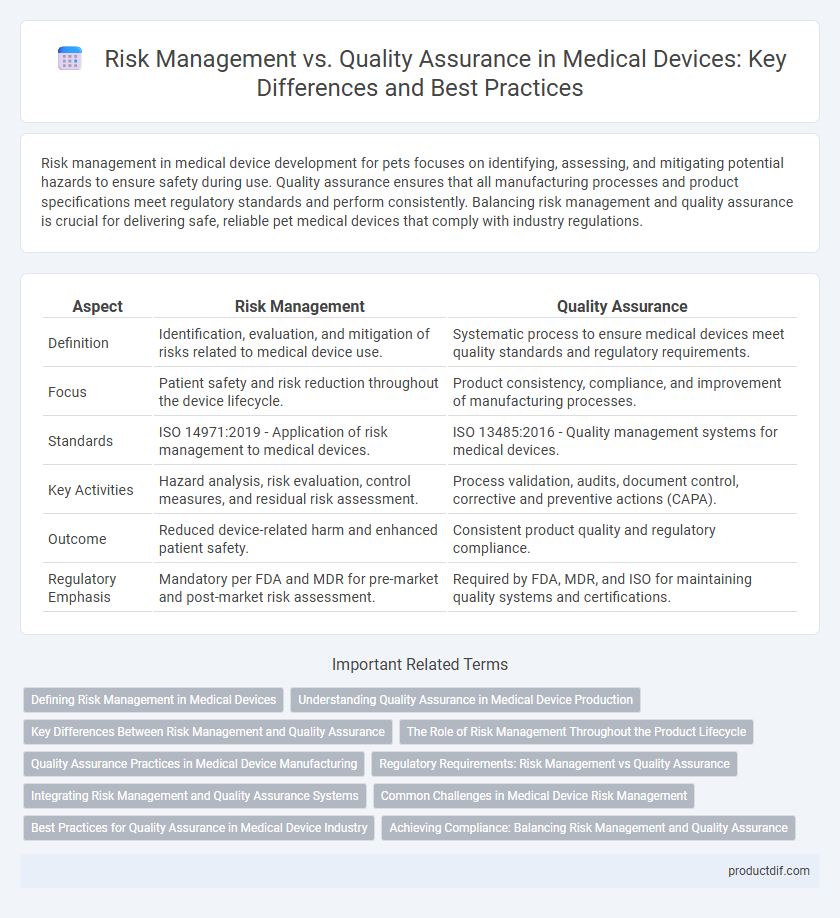

Risk management in medical device development for pets focuses on identifying, assessing, and mitigating potential hazards to ensure safety during use. Quality assurance ensures that all manufacturing processes and product specifications meet regulatory standards and perform consistently. Balancing risk management and quality assurance is crucial for delivering safe, reliable pet medical devices that comply with industry regulations.

Table of Comparison

| Aspect | Risk Management | Quality Assurance |

|---|---|---|

| Definition | Identification, evaluation, and mitigation of risks related to medical device use. | Systematic process to ensure medical devices meet quality standards and regulatory requirements. |

| Focus | Patient safety and risk reduction throughout the device lifecycle. | Product consistency, compliance, and improvement of manufacturing processes. |

| Standards | ISO 14971:2019 - Application of risk management to medical devices. | ISO 13485:2016 - Quality management systems for medical devices. |

| Key Activities | Hazard analysis, risk evaluation, control measures, and residual risk assessment. | Process validation, audits, document control, corrective and preventive actions (CAPA). |

| Outcome | Reduced device-related harm and enhanced patient safety. | Consistent product quality and regulatory compliance. |

| Regulatory Emphasis | Mandatory per FDA and MDR for pre-market and post-market risk assessment. | Required by FDA, MDR, and ISO for maintaining quality systems and certifications. |

Defining Risk Management in Medical Devices

Risk management in medical devices involves systematically identifying, evaluating, and mitigating potential hazards throughout the product lifecycle to ensure patient safety and regulatory compliance. It includes activities such as risk analysis, risk evaluation, risk control, and post-market surveillance, adhering to standards like ISO 14971. Quality assurance, while encompassing broader process controls for consistent product quality, integrates risk management principles to minimize device-related risks and enhance overall safety and effectiveness.

Understanding Quality Assurance in Medical Device Production

Quality assurance in medical device production ensures compliance with regulatory standards such as ISO 13485, focusing on systematic processes that maintain product safety and effectiveness. Risk management identifies potential hazards and implements controls, but quality assurance encompasses comprehensive activities including process validation, documentation, and corrective actions to guarantee consistent product quality. Effective quality assurance integrates risk management principles to proactively prevent defects and meet stringent healthcare industry requirements.

Key Differences Between Risk Management and Quality Assurance

Risk management in medical devices focuses on identifying, assessing, and mitigating potential hazards to ensure patient safety, while quality assurance ensures processes and products consistently meet regulatory standards and specifications. Risk management involves systematic evaluation of device-related risks throughout the entire product lifecycle, whereas quality assurance emphasizes process control, documentation, and compliance with standards like ISO 13485. Key differences include risk management's proactive hazard control versus quality assurance's preventive approach to maintaining overall product quality and regulatory adherence.

The Role of Risk Management Throughout the Product Lifecycle

Risk management in medical devices systematically identifies, evaluates, and mitigates potential hazards from design to disposal, ensuring patient safety and regulatory compliance. It integrates risk analysis, evaluation, control, and review processes continuously throughout the product lifecycle, reducing the likelihood of adverse events. Quality assurance complements this by validating that risk controls are effectively implemented and maintained within manufacturing and clinical performance standards.

Quality Assurance Practices in Medical Device Manufacturing

Quality assurance practices in medical device manufacturing encompass systematic procedures to ensure products meet regulatory standards and safety requirements, including design control, process validation, and corrective/preventive actions. These practices involve rigorous testing, documentation, and compliance with ISO 13485 to maintain consistent product quality and mitigate risks associated with device failure. Effective quality assurance integrates supplier management, training programs, and audit processes to uphold manufacturing reliability and patient safety.

Regulatory Requirements: Risk Management vs Quality Assurance

Risk management in medical devices centers on identifying, assessing, and mitigating potential hazards to ensure patient safety, complying with ISO 14971 standards and FDA regulations such as 21 CFR Part 820. Quality assurance focuses on systematic processes to maintain product quality and consistency, adhering to regulatory frameworks like ISO 13485 and Good Manufacturing Practices (GMP). Regulatory requirements mandate rigorous documentation and continuous monitoring within both risk management and quality assurance to achieve compliance and safeguard public health.

Integrating Risk Management and Quality Assurance Systems

Integrating risk management and quality assurance systems in medical device development ensures comprehensive compliance with regulatory standards such as ISO 13485 and ISO 14971. This integration enables continuous monitoring and mitigation of potential hazards while maintaining product quality and safety throughout the device lifecycle. Streamlined processes improve traceability, reduce non-conformities, and enhance patient safety by aligning risk controls with quality objectives.

Common Challenges in Medical Device Risk Management

Common challenges in medical device risk management include identifying all potential hazards, accurately assessing risk levels, and effectively implementing control measures. Inconsistent risk evaluation criteria and inadequate communication between cross-functional teams often hinder proper risk mitigation. Balancing stringent regulatory requirements with practical quality assurance processes remains a critical obstacle for manufacturers.

Best Practices for Quality Assurance in Medical Device Industry

Effective quality assurance in the medical device industry integrates rigorous risk management to ensure product safety and regulatory compliance. Best practices include continuous monitoring of production processes, thorough documentation, and proactive identification of potential hazards using standards like ISO 13485 and ISO 14971. Implementing these strategies helps minimize defects, improve patient safety, and maintain adherence to FDA and international regulatory requirements.

Achieving Compliance: Balancing Risk Management and Quality Assurance

Achieving compliance in medical device manufacturing requires a strategic balance between risk management and quality assurance to ensure product safety and regulatory adherence. Risk management systematically identifies, evaluates, and mitigates potential hazards, while quality assurance enforces processes and controls that maintain product consistency and reliability. Integrating these disciplines enables manufacturers to meet FDA, ISO 13485, and MDR standards effectively, reducing the likelihood of recalls and enhancing patient safety.

Risk management vs Quality assurance Infographic

productdif.com

productdif.com