Sterilization validation ensures that medical devices are free from all viable microorganisms, confirming the effectiveness of sterilization processes like steam, ethylene oxide, or irradiation. Cleaning validation, on the other hand, verifies that residue from biological materials, chemicals, or cleaning agents is effectively removed to prevent interference with sterilization or patient safety. Both validations are critical to patient safety but address different stages of infection control in medical device reprocessing.

Table of Comparison

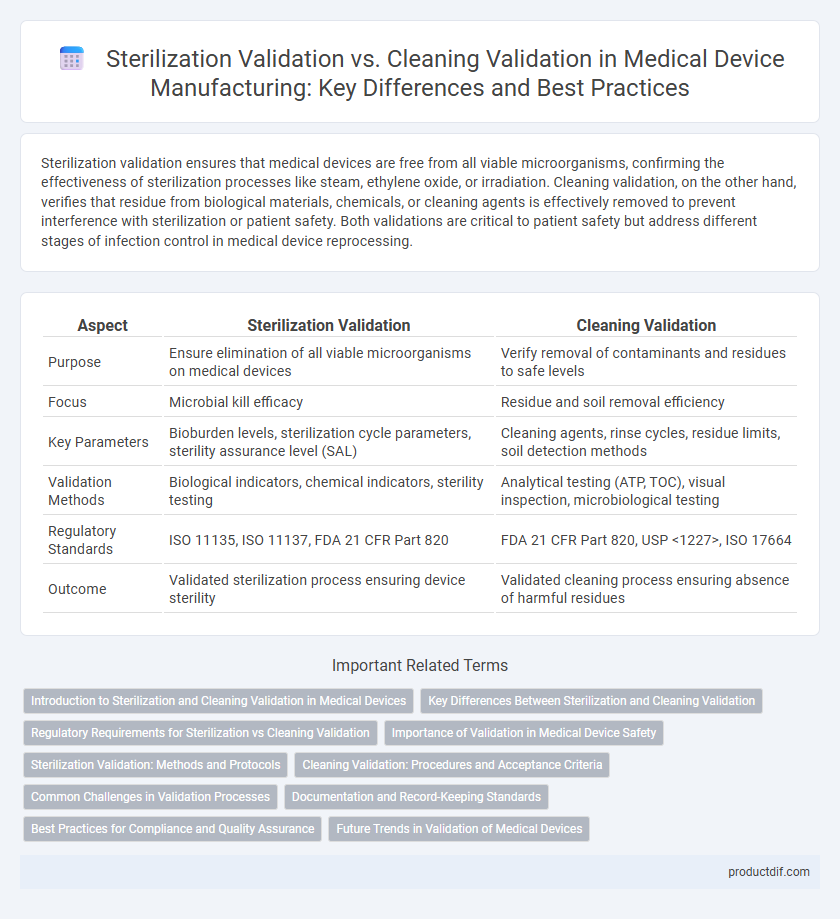

| Aspect | Sterilization Validation | Cleaning Validation |

|---|---|---|

| Purpose | Ensure elimination of all viable microorganisms on medical devices | Verify removal of contaminants and residues to safe levels |

| Focus | Microbial kill efficacy | Residue and soil removal efficiency |

| Key Parameters | Bioburden levels, sterilization cycle parameters, sterility assurance level (SAL) | Cleaning agents, rinse cycles, residue limits, soil detection methods |

| Validation Methods | Biological indicators, chemical indicators, sterility testing | Analytical testing (ATP, TOC), visual inspection, microbiological testing |

| Regulatory Standards | ISO 11135, ISO 11137, FDA 21 CFR Part 820 | FDA 21 CFR Part 820, USP <1227>, ISO 17664 |

| Outcome | Validated sterilization process ensuring device sterility | Validated cleaning process ensuring absence of harmful residues |

Introduction to Sterilization and Cleaning Validation in Medical Devices

Sterilization validation in medical devices ensures that sterilization processes consistently achieve a predefined sterility assurance level, eliminating all viable microorganisms from the device. Cleaning validation verifies the effective removal of soil, contaminants, and residues to prevent interference with sterilization and ensure patient safety. Both validation processes are critical to comply with regulatory standards such as ISO 13485 and FDA requirements, guaranteeing device safety and effectiveness throughout the manufacturing lifecycle.

Key Differences Between Sterilization and Cleaning Validation

Sterilization validation ensures the complete elimination of all microbial life on a medical device, verified through bioburden testing, microbial indicators, and sterility assurance levels (SAL). Cleaning validation focuses on the effective removal of soil, residues, and contaminants, using methods such as protein assays, residue analysis, and visual inspection to meet established acceptance criteria. Key differences include the target outcomes--sterilization validation confirms microbial lethality whereas cleaning validation confirms contaminant removal--and the testing methods that are specific to each validation type.

Regulatory Requirements for Sterilization vs Cleaning Validation

Sterilization validation protocols must comply with regulatory standards such as ISO 11135 and ISO 11137, emphasizing microbial lethality and sterility assurance levels (SAL) to ensure patient safety. Cleaning validation requirements, governed by FDA and EMA guidelines, focus on the removal of bioburden, residual chemicals, and endotoxins, with acceptance criteria based on product-specific risk assessments. Regulatory bodies mandate thorough documentation and routine verification for both validations to maintain compliance throughout the medical device lifecycle.

Importance of Validation in Medical Device Safety

Sterilization validation ensures that medical devices are free from all viable microorganisms, critical for preventing infections and ensuring patient safety during surgical procedures. Cleaning validation verifies the effective removal of contaminants such as bioburden, residues, and cleaning agents, which is vital to maintain device functionality and prepare for sterilization. Both validations are integral to regulatory compliance, minimizing risks, and guaranteeing the overall safety and efficacy of medical devices used in healthcare settings.

Sterilization Validation: Methods and Protocols

Sterilization validation in medical devices involves rigorous methods such as biological indicators, chemical indicators, and physical monitoring to ensure the complete elimination of microbial life. Protocols typically include predefined sterilization cycles using steam, ethylene oxide, or radiation, validated through bioburden assessment and sterility testing. This process confirms that sterilization parameters meet regulatory standards, ensuring device safety and efficacy before clinical use.

Cleaning Validation: Procedures and Acceptance Criteria

Cleaning validation in medical device manufacturing ensures the removal of residues and contaminants to meet stringent safety standards. Procedures involve selecting appropriate cleaning agents, defining test methods such as ATP bioluminescence or HPLC for residue detection, and establishing sampling protocols like swab or rinse tests. Acceptance criteria are based on allowable residue limits, typically set as a fraction of the minimum therapeutic dose or health-based exposure limits, ensuring product safety and compliance with regulatory bodies like the FDA and ISO 13485.

Common Challenges in Validation Processes

Sterilization validation and cleaning validation in medical device manufacturing both face challenges such as ensuring reproducibility across complex geometries and diverse materials. Common difficulties include verifying the complete removal of bioburden and residual contaminants without compromising device integrity. Establishing precise acceptance criteria and maintaining consistent environmental controls are crucial for successful validation outcomes.

Documentation and Record-Keeping Standards

Sterilization validation requires comprehensive documentation demonstrating the effectiveness of microbial kill processes, including detailed cycle parameters, biological indicator results, and equipment calibration records. Cleaning validation documentation focuses on evidence of contaminant removal, such as residue limits, analytical testing methods, and verification protocols to ensure absence of soil or bio-burden. Both require rigorous record-keeping with traceability, audit trails, and compliance to regulatory standards like ISO 13485 and FDA 21 CFR Part 820 to ensure product safety and quality.

Best Practices for Compliance and Quality Assurance

Sterilization validation ensures the complete elimination of all microbial life on medical devices, employing rigorous biological indicators and process parameters to meet regulatory standards like ISO 11135 and ISO 17665. Cleaning validation verifies the removal of soil, debris, and residuals using quantitative analytical methods such as ATP bioluminescence or TOC analysis, essential for preventing contamination and ensuring device safety. Implementing comprehensive documentation, risk assessments, and continuous monitoring forms best practices that guarantee compliance with FDA and EU MDR requirements while maintaining high-quality assurance.

Future Trends in Validation of Medical Devices

Future trends in sterilization validation of medical devices emphasize integrating real-time monitoring technologies and advanced analytics to ensure consistent microbial control. Cleaning validation advances focus on adopting automated, sensor-based systems that provide precise residue detection and verification, enhancing overall process reliability. Embracing digital twin models and machine learning algorithms is transforming validation protocols, promoting predictive maintenance and adaptive process optimization for both sterilization and cleaning stages.

Sterilization Validation vs Cleaning Validation Infographic

productdif.com

productdif.com