SCADA systems provide centralized monitoring and control across multiple PLCs, offering comprehensive data visualization and remote accessibility for complex industrial processes. PLCs are dedicated control units designed to execute specific automation tasks with high reliability and real-time processing capabilities. Combining SCADA with PLCs enhances operational efficiency by integrating detailed control at the device level with broad supervisory oversight.

Table of Comparison

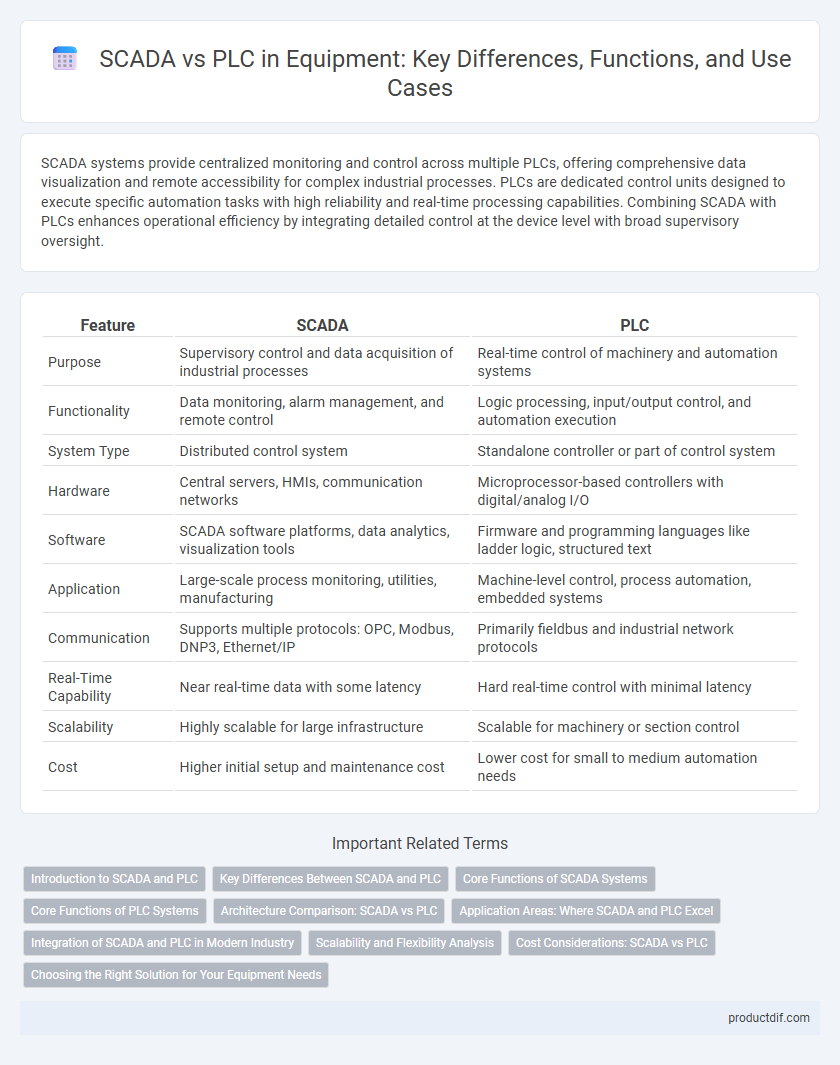

| Feature | SCADA | PLC |

|---|---|---|

| Purpose | Supervisory control and data acquisition of industrial processes | Real-time control of machinery and automation systems |

| Functionality | Data monitoring, alarm management, and remote control | Logic processing, input/output control, and automation execution |

| System Type | Distributed control system | Standalone controller or part of control system |

| Hardware | Central servers, HMIs, communication networks | Microprocessor-based controllers with digital/analog I/O |

| Software | SCADA software platforms, data analytics, visualization tools | Firmware and programming languages like ladder logic, structured text |

| Application | Large-scale process monitoring, utilities, manufacturing | Machine-level control, process automation, embedded systems |

| Communication | Supports multiple protocols: OPC, Modbus, DNP3, Ethernet/IP | Primarily fieldbus and industrial network protocols |

| Real-Time Capability | Near real-time data with some latency | Hard real-time control with minimal latency |

| Scalability | Highly scalable for large infrastructure | Scalable for machinery or section control |

| Cost | Higher initial setup and maintenance cost | Lower cost for small to medium automation needs |

Introduction to SCADA and PLC

SCADA (Supervisory Control and Data Acquisition) systems enable centralized monitoring and control of industrial processes through real-time data collection and analysis, enhancing operational efficiency. PLCs (Programmable Logic Controllers) provide localized automation by executing programmed control tasks with high reliability and fast response times in machinery and production lines. Integrating SCADA with PLCs creates a comprehensive solution that combines data acquisition, system control, and process visualization for optimized industrial automation.

Key Differences Between SCADA and PLC

SCADA (Supervisory Control and Data Acquisition) systems primarily focus on centralized monitoring and control of industrial processes, providing real-time data visualization and alarm management across wide areas. PLCs (Programmable Logic Controllers) are specialized hardware devices designed for executing control logic directly on machinery, ensuring real-time automation and precise timing. The key difference lies in SCADA's role in data acquisition and system-wide oversight, whereas PLCs handle discrete control tasks and automation at the equipment level.

Core Functions of SCADA Systems

SCADA systems primarily focus on centralized monitoring and real-time data acquisition from multiple remote sites, enabling operators to control equipment and processes efficiently through human-machine interfaces (HMIs). They provide advanced data analytics, event detection, and historical data logging to optimize operational performance and maintenance scheduling. Unlike PLCs, which execute localized control logic, SCADA integrates vast networks of PLCs and other field devices for comprehensive system oversight and decision support.

Core Functions of PLC Systems

PLC systems primarily execute real-time control tasks by continuously monitoring input signals, processing logic instructions, and triggering outputs to manage industrial machinery. They feature deterministic operation, rugged hardware designed for harsh environments, and modular I/O configurations supporting diverse automation needs. Core functions also include seamless communication with SCADA systems, enabling supervisory control and data acquisition for comprehensive process management.

Architecture Comparison: SCADA vs PLC

SCADA systems feature a hierarchical architecture consisting of centralized servers, remote terminal units (RTUs), and human-machine interfaces (HMIs), enabling real-time monitoring and control over extensive industrial processes. PLC architecture is modular, designed for localized control with integrated input/output modules and a processor that executes automated tasks in real-time. SCADA provides system-wide supervision through distributed network communication, whereas PLCs deliver fast, deterministic control at the device level within industrial automation environments.

Application Areas: Where SCADA and PLC Excel

SCADA systems excel in large-scale industrial processes requiring remote monitoring and control, such as water treatment plants, power generation, and oil and gas pipelines. PLCs are best suited for localized automation tasks, including manufacturing assembly lines, robotic control, and machine operation due to their real-time processing capabilities. Combining SCADA's supervisory control with PLC's precise execution optimizes complex industrial automation environments.

Integration of SCADA and PLC in Modern Industry

Integration of SCADA and PLC systems enhances real-time data acquisition and centralized control in modern industrial environments, driving efficient monitoring and automation. PLCs execute precise control tasks and manage on-site equipment, while SCADA provides a comprehensive interface for overseeing operations, data visualization, and fault diagnostics. This synergy improves predictive maintenance, reduces downtime, and supports Industry 4.0 initiatives by enabling seamless communication between machinery and enterprise-level management systems.

Scalability and Flexibility Analysis

SCADA systems offer extensive scalability by managing multiple PLCs across large, distributed industrial environments, enabling real-time data acquisition and centralized control. PLCs provide high flexibility for specific automation tasks with customizable programming and modular hardware, but their scalability is limited to localized control areas. Integrating SCADA with PLCs enhances overall system adaptability, supporting complex, scalable industrial automation solutions.

Cost Considerations: SCADA vs PLC

PLC systems typically have lower initial costs due to their simpler architecture and focused control capabilities, making them cost-effective for small to medium-scale applications. SCADA systems involve higher upfront investment because of the need for extensive hardware, software licenses, and communication infrastructure, but they enable centralized monitoring and control across larger or more complex operations. Maintenance costs for PLCs are generally lower, while SCADA systems may incur higher expenses related to software updates, cybersecurity, and network management.

Choosing the Right Solution for Your Equipment Needs

SCADA systems provide comprehensive monitoring and control across multiple devices and sites, ideal for large-scale equipment operations requiring real-time data integration. PLCs offer focused, reliable automation control tailored to specific machines, making them suitable for straightforward, single-process equipment setups. Evaluating the complexity, scalability, and real-time data requirements of your equipment is essential to determine whether a SCADA or PLC solution best aligns with your operational goals.

SCADA vs PLC Infographic

productdif.com

productdif.com