V&V testing in medical devices ensures comprehensive validation and verification of design, functionality, and regulatory compliance, confirming the product meets user needs and safety standards. Bench testing focuses on the controlled, physical evaluation of device components and subsystems to identify performance issues under simulated conditions. Combining V&V testing with bench testing enhances device reliability and mitigates risks before clinical application.

Table of Comparison

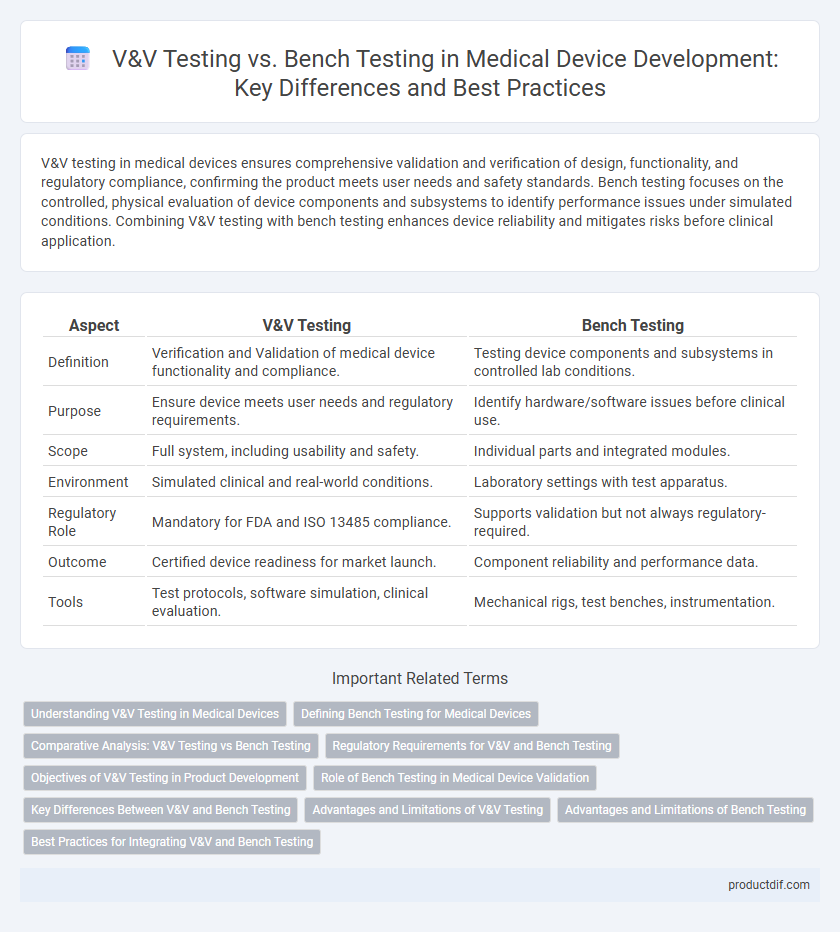

| Aspect | V&V Testing | Bench Testing |

|---|---|---|

| Definition | Verification and Validation of medical device functionality and compliance. | Testing device components and subsystems in controlled lab conditions. |

| Purpose | Ensure device meets user needs and regulatory requirements. | Identify hardware/software issues before clinical use. |

| Scope | Full system, including usability and safety. | Individual parts and integrated modules. |

| Environment | Simulated clinical and real-world conditions. | Laboratory settings with test apparatus. |

| Regulatory Role | Mandatory for FDA and ISO 13485 compliance. | Supports validation but not always regulatory-required. |

| Outcome | Certified device readiness for market launch. | Component reliability and performance data. |

| Tools | Test protocols, software simulation, clinical evaluation. | Mechanical rigs, test benches, instrumentation. |

Understanding V&V Testing in Medical Devices

V&V testing in medical devices ensures comprehensive verification and validation of design outputs against user needs and regulatory requirements, confirming device safety and effectiveness. Bench testing primarily evaluates device performance in controlled environments to identify functional issues and mechanical reliability, but V&V encompasses broader compliance and clinical applicability. Understanding V&V testing is crucial for meeting FDA standards and IEC 62304 software lifecycle processes, ensuring products are safe for patient use and market-ready.

Defining Bench Testing for Medical Devices

Bench testing for medical devices involves evaluating the device's functionality, safety, and performance under controlled laboratory conditions without involving human subjects. This testing method simulates real-world operational scenarios to identify design flaws, ensure compliance with regulatory standards like ISO 13485, and validate device components before clinical trials. Bench testing provides critical data that supports Verification and Validation (V&V) processes, ultimately reducing risks and enhancing device reliability.

Comparative Analysis: V&V Testing vs Bench Testing

V&V testing (Verification and Validation) assesses the medical device's compliance with user needs and regulatory requirements, ensuring functionality and safety in real-world scenarios. Bench testing evaluates individual components or subsystems in a controlled laboratory setting to identify performance issues early in the development cycle. While bench testing focuses on technical aspects and defect identification, V&V testing provides comprehensive validation against clinical use cases and regulatory standards.

Regulatory Requirements for V&V and Bench Testing

V&V testing in medical devices ensures compliance with regulatory requirements set by authorities such as the FDA and ISO 13485, focusing on verifying that the device meets user needs and intended uses through comprehensive validation and verification protocols. Bench testing primarily addresses functional and performance criteria under controlled laboratory conditions, supporting design verification but often requiring supplement with V&V activities to fulfill regulatory mandates. Regulatory bodies emphasize documented evidence from both V&V and bench testing to demonstrate safety, efficacy, and conformity before market approval.

Objectives of V&V Testing in Product Development

V&V testing in medical device development ensures that the product meets specified requirements and intended use through rigorous validation and verification processes. It focuses on identifying design flaws, verifying safety and performance standards, and validating real-world functionality under simulated clinical conditions. This comprehensive assessment reduces risks, improves product reliability, and supports regulatory compliance for successful market approval.

Role of Bench Testing in Medical Device Validation

Bench testing plays a critical role in medical device validation by providing a controlled environment to evaluate device performance, functionality, and safety before clinical trials. It allows for repeated, precise measurements and simulations of real-world conditions to identify defects and ensure compliance with regulatory standards such as ISO 13485 and FDA requirements. This method complements V&V testing by enabling early detection of design flaws, reducing risks, and accelerating product development timelines.

Key Differences Between V&V and Bench Testing

V&V testing (Verification and Validation) evaluates medical devices against user needs and regulatory requirements, ensuring safety, efficacy, and compliance throughout development and post-production stages. Bench testing focuses on experimentally assessing device performance under controlled laboratory conditions, measuring functionality, durability, and mechanical properties without clinical variables. Unlike bench testing's component-level analysis, V&V involves comprehensive system-level evaluation including software validation and user interface verification critical for FDA approval and CE marking.

Advantages and Limitations of V&V Testing

Verification and Validation (V&V) testing in medical devices ensures that the product meets design specifications and user needs, enhancing safety and regulatory compliance. V&V testing allows early identification of design flaws and functional errors by simulating real-world conditions more comprehensively than bench testing. However, V&V testing can be time-consuming and costly, with potential limitations in replicating all clinical scenarios compared to the controlled environment of bench testing.

Advantages and Limitations of Bench Testing

Bench testing offers controlled, repeatable conditions for verifying medical device functionality, enabling early detection of design flaws and ensuring compliance with specifications. Its limitations include the inability to fully replicate complex clinical environments and patient interactions, which can lead to gaps in performance assessment. Complementing bench testing with V&V testing helps address these limitations by validating the device's safety and effectiveness in real-world scenarios.

Best Practices for Integrating V&V and Bench Testing

Integrating V&V (Verification and Validation) testing with bench testing enhances the reliability of medical devices by aligning functional performance with real-world operational scenarios. Best practices include developing comprehensive test protocols that cover both design specifications and user environments, ensuring traceability between requirements and test outcomes. Utilizing synchronized data collection from bench tests during V&V phases accelerates issue identification and supports robust regulatory compliance.

V&V testing vs Bench testing Infographic

productdif.com

productdif.com