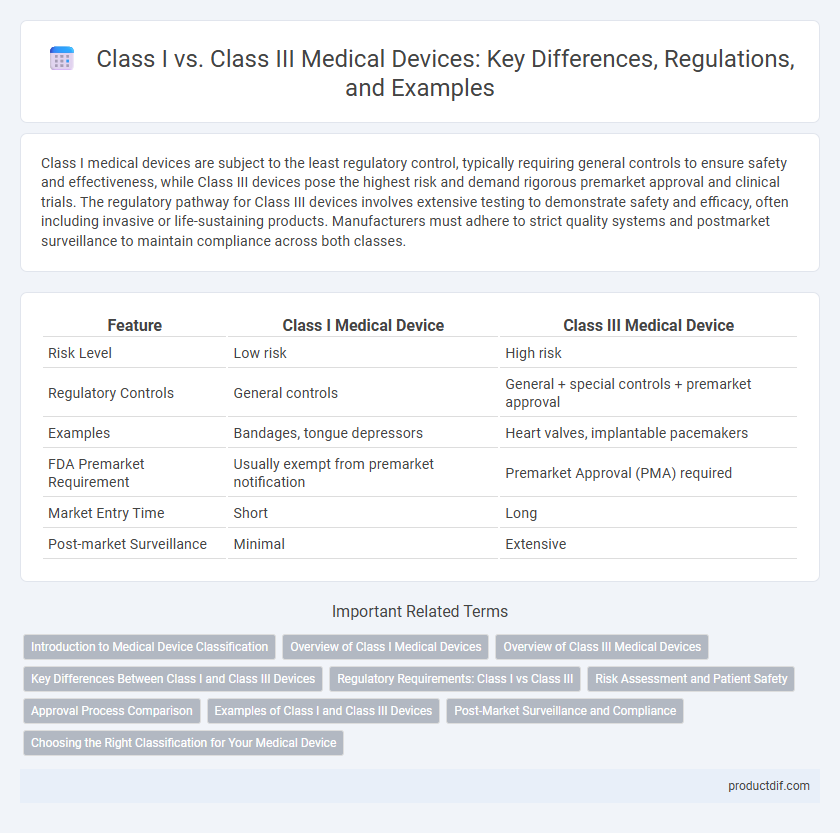

Class I medical devices are subject to the least regulatory control, typically requiring general controls to ensure safety and effectiveness, while Class III devices pose the highest risk and demand rigorous premarket approval and clinical trials. The regulatory pathway for Class III devices involves extensive testing to demonstrate safety and efficacy, often including invasive or life-sustaining products. Manufacturers must adhere to strict quality systems and postmarket surveillance to maintain compliance across both classes.

Table of Comparison

| Feature | Class I Medical Device | Class III Medical Device |

|---|---|---|

| Risk Level | Low risk | High risk |

| Regulatory Controls | General controls | General + special controls + premarket approval |

| Examples | Bandages, tongue depressors | Heart valves, implantable pacemakers |

| FDA Premarket Requirement | Usually exempt from premarket notification | Premarket Approval (PMA) required |

| Market Entry Time | Short | Long |

| Post-market Surveillance | Minimal | Extensive |

Introduction to Medical Device Classification

Medical device classification categorizes devices based on risk levels, with Class I representing low-risk devices such as bandages and handheld surgical instruments, while Class III encompasses high-risk devices like implantable pacemakers and heart valves that require rigorous regulatory controls. Class I devices typically undergo general controls including good manufacturing practices and proper labeling whereas Class III devices demand premarket approval (PMA) involving scientific review to ensure safety and efficacy. Understanding these distinctions is crucial for compliance with regulatory frameworks such as the FDA's classification system and the EU Medical Device Regulation (MDR).

Overview of Class I Medical Devices

Class I medical devices are low-risk products subject to the least regulatory controls by the FDA, typically including items such as bandages, examination gloves, and handheld surgical instruments. These devices generally require compliance with General Controls, which encompass Good Manufacturing Practices (GMP), proper labeling, and facility registration, but they rarely need premarket notification or approval. In contrast, Class III devices, like pacemakers and heart valves, pose the highest risk and must undergo rigorous Premarket Approval (PMA) processes to ensure safety and effectiveness.

Overview of Class III Medical Devices

Class III medical devices represent the highest risk category, requiring rigorous regulatory scrutiny due to their critical role in sustaining or supporting human life. These devices often involve complex technology, such as implantable pacemakers or heart valves, necessitating extensive clinical trials and premarket approval by regulatory bodies like the FDA. Unlike Class I devices, which are subject to general controls, Class III devices must demonstrate safety and efficacy through comprehensive data before market clearance.

Key Differences Between Class I and Class III Devices

Class I medical devices are low-risk, typically requiring general controls such as proper labeling and manufacturing standards, while Class III devices pose the highest risk and usually need premarket approval (PMA) involving rigorous scientific review. Class I devices include items like bandages and handheld surgical instruments, whereas Class III devices encompass implantable pacemakers and heart valves that sustain or support life. The regulatory scrutiny and clinical evidence required for Class III devices are significantly more extensive compared to the simpler oversight for Class I devices.

Regulatory Requirements: Class I vs Class III

Class I medical devices are subject to general controls, including labeling, registration, and adherence to Good Manufacturing Practices (GMP), typically requiring only a 510(k) premarket notification or are exempt. Class III devices, representing the highest risk category, demand Premarket Approval (PMA), rigorous clinical trials, and comprehensive FDA evaluation to ensure safety and effectiveness. Regulatory requirements for Class III devices involve stringent post-market surveillance and manufacturing quality controls to mitigate risks associated with their critical use.

Risk Assessment and Patient Safety

Class I medical devices pose the lowest risk and require general controls, focusing on basic safety and effectiveness, while Class III devices present the highest risk and demand rigorous premarket approval with comprehensive risk assessment protocols. Risk assessment for Class III devices involves in-depth clinical evaluations, detailed failure mode analysis, and rigorous biocompatibility testing to ensure maximum patient safety. Effective regulatory oversight and robust safety measures are critical in Class III devices to mitigate risks such as device malfunction or adverse patient outcomes.

Approval Process Comparison

Class I medical devices undergo a relatively simple approval process, often requiring general controls such as registration, labeling, and good manufacturing practices, with many exempt from premarket notification. In contrast, Class III devices, which support or sustain human life or present potential unreasonable risk, require a rigorous premarket approval (PMA) process involving extensive clinical trials to demonstrate safety and effectiveness. The PMA process for Class III devices is stringent, time-consuming, and costly compared to the largely administrative clearance pathway for Class I devices.

Examples of Class I and Class III Devices

Class I medical devices include simple, low-risk products such as elastic bandages, tongue depressors, and manual surgical instruments, which require general controls for safety and effectiveness. Class III devices consist of high-risk products like implantable pacemakers, heart valves, and neurostimulators, necessitating rigorous premarket approval due to their potential impact on patient health. The classification system ensures appropriate regulatory measures align with the device's risk level and complexity.

Post-Market Surveillance and Compliance

Class I medical devices typically require general controls and minimal post-market surveillance due to their low-risk nature, whereas Class III devices mandate rigorous post-market surveillance, including routine reporting of adverse events and compliance with stringent FDA and international regulatory standards. Manufacturers of Class III devices must implement comprehensive risk management strategies and maintain detailed documentation to ensure continual compliance and patient safety. Enhanced post-market monitoring for Class III devices facilitates early detection of potential device failures and supports corrective actions, reducing overall healthcare risks.

Choosing the Right Classification for Your Medical Device

Selecting the appropriate classification for your medical device depends on its intended use and associated risk level, with Class I devices posing the lowest risk and Class III devices involving the highest risk requiring rigorous regulatory control. Class I devices typically include simple instruments like bandages, while Class III devices encompass life-supporting devices such as implantable pacemakers, necessitating premarket approval and extensive clinical evaluation. Understanding the specific regulatory requirements and compliance obligations for each class is essential to ensure safety, efficacy, and market access.

Class I vs Class III Infographic

productdif.com

productdif.com