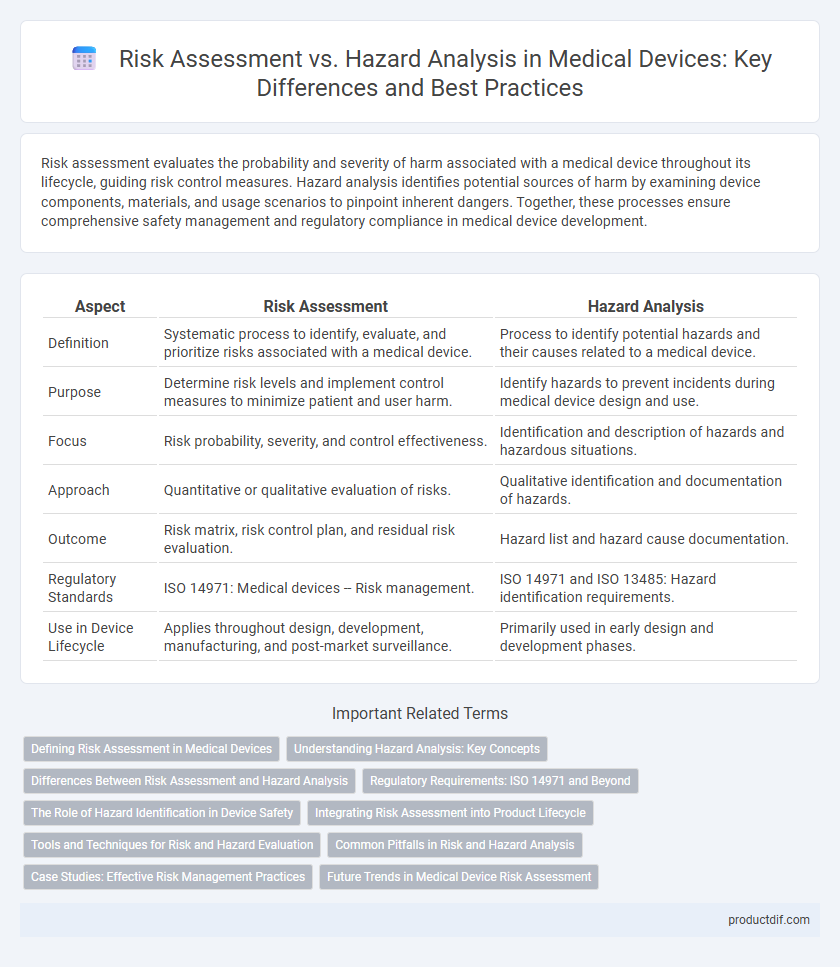

Risk assessment evaluates the probability and severity of harm associated with a medical device throughout its lifecycle, guiding risk control measures. Hazard analysis identifies potential sources of harm by examining device components, materials, and usage scenarios to pinpoint inherent dangers. Together, these processes ensure comprehensive safety management and regulatory compliance in medical device development.

Table of Comparison

| Aspect | Risk Assessment | Hazard Analysis |

|---|---|---|

| Definition | Systematic process to identify, evaluate, and prioritize risks associated with a medical device. | Process to identify potential hazards and their causes related to a medical device. |

| Purpose | Determine risk levels and implement control measures to minimize patient and user harm. | Identify hazards to prevent incidents during medical device design and use. |

| Focus | Risk probability, severity, and control effectiveness. | Identification and description of hazards and hazardous situations. |

| Approach | Quantitative or qualitative evaluation of risks. | Qualitative identification and documentation of hazards. |

| Outcome | Risk matrix, risk control plan, and residual risk evaluation. | Hazard list and hazard cause documentation. |

| Regulatory Standards | ISO 14971: Medical devices -- Risk management. | ISO 14971 and ISO 13485: Hazard identification requirements. |

| Use in Device Lifecycle | Applies throughout design, development, manufacturing, and post-market surveillance. | Primarily used in early design and development phases. |

Defining Risk Assessment in Medical Devices

Risk assessment in medical devices involves systematically identifying potential risks associated with device use, evaluating the probability and severity of harm, and determining appropriate risk control measures. It quantifies both inherent hazards and user-related factors, ensuring compliance with ISO 14971 standards for risk management in healthcare products. This process is critical for maintaining patient safety and device efficacy throughout the product lifecycle.

Understanding Hazard Analysis: Key Concepts

Hazard analysis in medical device risk management involves systematically identifying potential sources of harm associated with device use, focusing on the origin and nature of hazards before risk estimation. It prioritizes understanding failure modes, hazardous situations, and severity of harm to inform effective mitigation strategies. This process ensures comprehensive hazard identification, supporting compliance with standards like ISO 14971 for enhanced patient safety.

Differences Between Risk Assessment and Hazard Analysis

Risk assessment evaluates the probability and severity of harm arising from identified hazards in a medical device throughout its lifecycle, quantifying and prioritizing risks for mitigation. Hazard analysis systematically identifies and categorizes potential sources of harm or hazardous situations associated with device design, manufacturing, or use, serving as the foundational step in the risk management process. The primary difference lies in hazard analysis focusing on hazard identification and characterization, while risk assessment encompasses hazard probability, severity, and risk acceptability criteria to guide decision-making.

Regulatory Requirements: ISO 14971 and Beyond

Risk assessment under ISO 14971 mandates systematic identification, evaluation, and mitigation of risks associated with medical devices throughout their lifecycle. Hazard analysis focuses on recognizing potential sources of harm, forming a critical component within the broader risk management process stipulated by regulatory authorities such as the FDA and MDR. Compliance extends beyond ISO 14971, incorporating standards like IEC 60601 and guidelines from bodies like IMDRF to ensure comprehensive risk control and patient safety.

The Role of Hazard Identification in Device Safety

Hazard identification plays a crucial role in medical device safety by pinpointing potential sources of harm before they escalate into risks. It serves as the foundation for both risk assessment and hazard analysis, ensuring all possible dangers related to device design, materials, and usage are systematically recognized. Accurate hazard identification enhances the effectiveness of risk controls, ultimately reducing the likelihood of device-related injuries or malfunctions.

Integrating Risk Assessment into Product Lifecycle

Integrating risk assessment into the product lifecycle ensures continuous identification, evaluation, and mitigation of potential hazards associated with a medical device. Risk assessment provides a comprehensive evaluation of overall device risks, while hazard analysis focuses specifically on identifying and characterizing individual hazards. Embedding these processes throughout design, development, and post-market stages enhances device safety and regulatory compliance.

Tools and Techniques for Risk and Hazard Evaluation

Risk assessment in medical devices employs quantitative tools such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to systematically evaluate potential device malfunctions and their impacts on patient safety. Hazard analysis utilizes qualitative techniques including Preliminary Hazard Analysis (PHA) and Hazard and Operability Study (HAZOP) to identify and categorize hazards during early design stages. Integrating software-based simulation tools and real-world data analytics enhances precision in both risk and hazard evaluations, ensuring regulatory compliance with standards like ISO 14971.

Common Pitfalls in Risk and Hazard Analysis

Common pitfalls in risk assessment and hazard analysis for medical devices include inadequate identification of potential hazards, leading to incomplete risk evaluation. Failure to update assessments with new data or changes in device design further compromises safety effectiveness. Overlooking user-related factors and environmental conditions can result in underestimated risks and insufficient mitigation strategies.

Case Studies: Effective Risk Management Practices

Case studies in medical device development highlight that risk assessment systematically evaluates potential risks' probability and impact, while hazard analysis identifies specific sources of harm within device components or processes. Effective risk management practices integrate both approaches, ensuring comprehensive identification and mitigation of device-related risks to enhance patient safety and regulatory compliance. Evidence from industry projects demonstrates that combining quantitative risk assessment with detailed hazard analysis enables proactive issue resolution and improved device reliability.

Future Trends in Medical Device Risk Assessment

Future trends in medical device risk assessment emphasize the integration of artificial intelligence and machine learning to predict and mitigate potential hazards more accurately. Enhanced data analytics enable real-time monitoring and dynamic risk management throughout the device lifecycle. Regulatory frameworks are evolving to incorporate adaptive risk assessment models, ensuring improved patient safety and compliance.

Risk Assessment vs Hazard Analysis Infographic

productdif.com

productdif.com