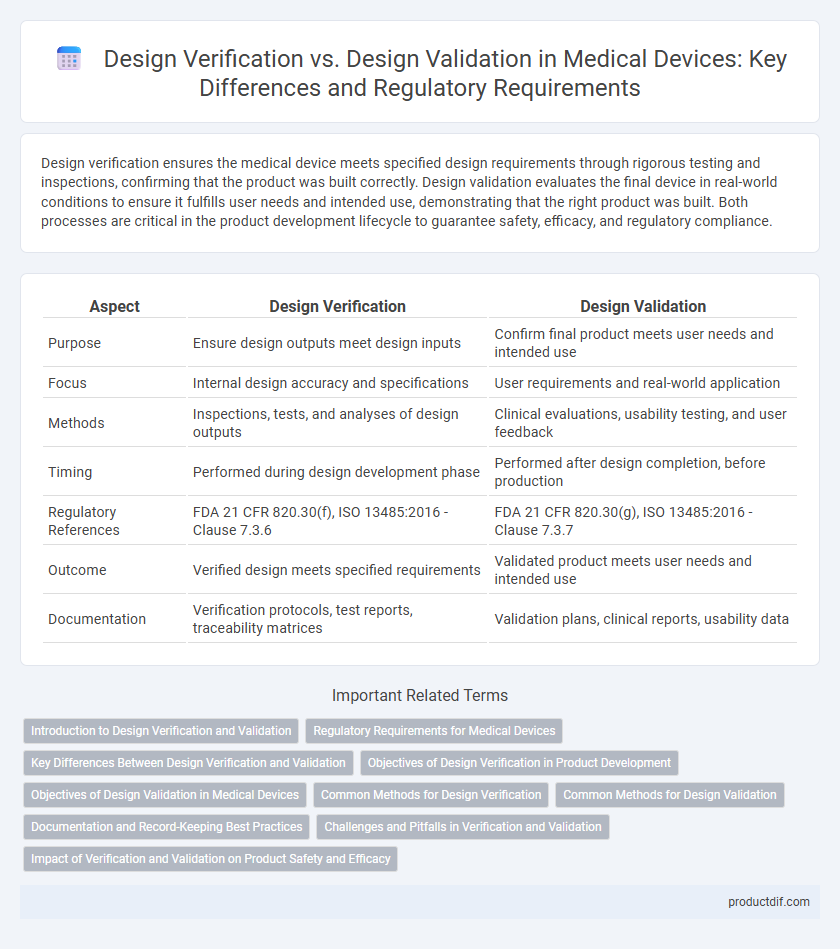

Design verification ensures the medical device meets specified design requirements through rigorous testing and inspections, confirming that the product was built correctly. Design validation evaluates the final device in real-world conditions to ensure it fulfills user needs and intended use, demonstrating that the right product was built. Both processes are critical in the product development lifecycle to guarantee safety, efficacy, and regulatory compliance.

Table of Comparison

| Aspect | Design Verification | Design Validation |

|---|---|---|

| Purpose | Ensure design outputs meet design inputs | Confirm final product meets user needs and intended use |

| Focus | Internal design accuracy and specifications | User requirements and real-world application |

| Methods | Inspections, tests, and analyses of design outputs | Clinical evaluations, usability testing, and user feedback |

| Timing | Performed during design development phase | Performed after design completion, before production |

| Regulatory References | FDA 21 CFR 820.30(f), ISO 13485:2016 - Clause 7.3.6 | FDA 21 CFR 820.30(g), ISO 13485:2016 - Clause 7.3.7 |

| Outcome | Verified design meets specified requirements | Validated product meets user needs and intended use |

| Documentation | Verification protocols, test reports, traceability matrices | Validation plans, clinical reports, usability data |

Introduction to Design Verification and Validation

Design Verification ensures that a medical device meets specified design inputs through rigorous testing and analysis, confirming that the product is built correctly. Design Validation assesses the final medical device under actual or simulated use conditions to ensure it fulfills user needs and intended purposes. Both processes are critical for regulatory compliance and patient safety in the medical device development lifecycle.

Regulatory Requirements for Medical Devices

Design Verification for medical devices ensures that design outputs meet specified design inputs through objective evidence, aligning with regulatory standards such as FDA 21 CFR 820.30(f) and ISO 13485. Design Validation confirms that the final product fulfills user needs and intended uses in actual or simulated environments, complying with FDA 21 CFR 820.30(g) and ISO 14971 risk management principles. Both processes are critical for regulatory approval, minimizing risk, and ensuring device safety and effectiveness throughout the product lifecycle.

Key Differences Between Design Verification and Validation

Design Verification ensures a medical device meets specified design inputs by testing and reviewing prototypes against technical requirements, emphasizing accuracy and completeness. Design Validation confirms the device fulfills user needs and intended uses in real-world conditions, often involving clinical evaluations or user trials. Verification focuses on "building the product right," while validation emphasizes "building the right product" to ensure safety and effectiveness.

Objectives of Design Verification in Product Development

Design Verification aims to ensure that the medical device meets all specified design inputs, confirming accuracy and completeness through rigorous testing and inspections. It focuses on identifying design errors early in product development to reduce risks and avoid costly revisions. Verification activities include component-level checks and performance evaluations aligned with regulatory requirements such as ISO 13485 and FDA 21 CFR Part 820.

Objectives of Design Validation in Medical Devices

Design Validation in medical devices aims to ensure the device meets user needs and intended uses under actual or simulated conditions. It confirms the product's performance, safety, and efficacy align with clinical requirements and regulatory standards such as ISO 13485 and FDA guidelines. This process helps identify potential risks and usability issues before market release, enhancing patient safety and device reliability.

Common Methods for Design Verification

Common methods for design verification in medical devices include inspections, measurements, and testing to ensure the product meets specified design input requirements. Techniques such as functional testing, software verification, and risk analysis are employed to confirm compliance with regulatory standards like ISO 13485 and FDA 21 CFR Part 820. Verification activities focus on objective evidence that the design outputs accurately reflect the design inputs to prevent defects before clinical use.

Common Methods for Design Validation

Common methods for design validation in medical devices include clinical evaluations, simulated use testing, and user needs assessment to ensure the device meets intended performance and safety requirements. Validation often involves pilot production runs and usability testing under real-world conditions to confirm the device functions correctly for end-users. These methods complement design verification processes, which focus on confirming design outputs meet specified design inputs.

Documentation and Record-Keeping Best Practices

Design verification requires comprehensive documentation of test plans, protocols, and results to confirm that the medical device meets specified design input requirements. Design validation demands meticulous records of clinical evaluations, user feedback, and real-world performance to ensure the device fulfills intended use safely and effectively. Maintaining traceable, organized documentation for both processes supports regulatory compliance and facilitates audits in medical device development.

Challenges and Pitfalls in Verification and Validation

Challenges in design verification often include incomplete test coverage and inadequate traceability between requirements and test cases, leading to missed defects and non-compliance with regulatory standards such as ISO 13485. Design validation pitfalls frequently arise from selecting inappropriate clinical evaluation methods or insufficient real-world usage testing, resulting in gaps in user needs fulfillment and potential safety risks. Ensuring robust documentation and maintaining clear communication between cross-functional teams are critical to overcoming these challenges in medical device development.

Impact of Verification and Validation on Product Safety and Efficacy

Design Verification ensures that a medical device meets predefined specifications and regulatory standards, directly impacting product safety by identifying design flaws early in development. Design Validation confirms that the final product fulfills user needs and intended use in real-world conditions, thereby validating efficacy and minimizing clinical risks. Together, these processes mitigate the risk of device failure and enhance patient safety and therapeutic outcomes.

Design Verification vs Design Validation Infographic

productdif.com

productdif.com