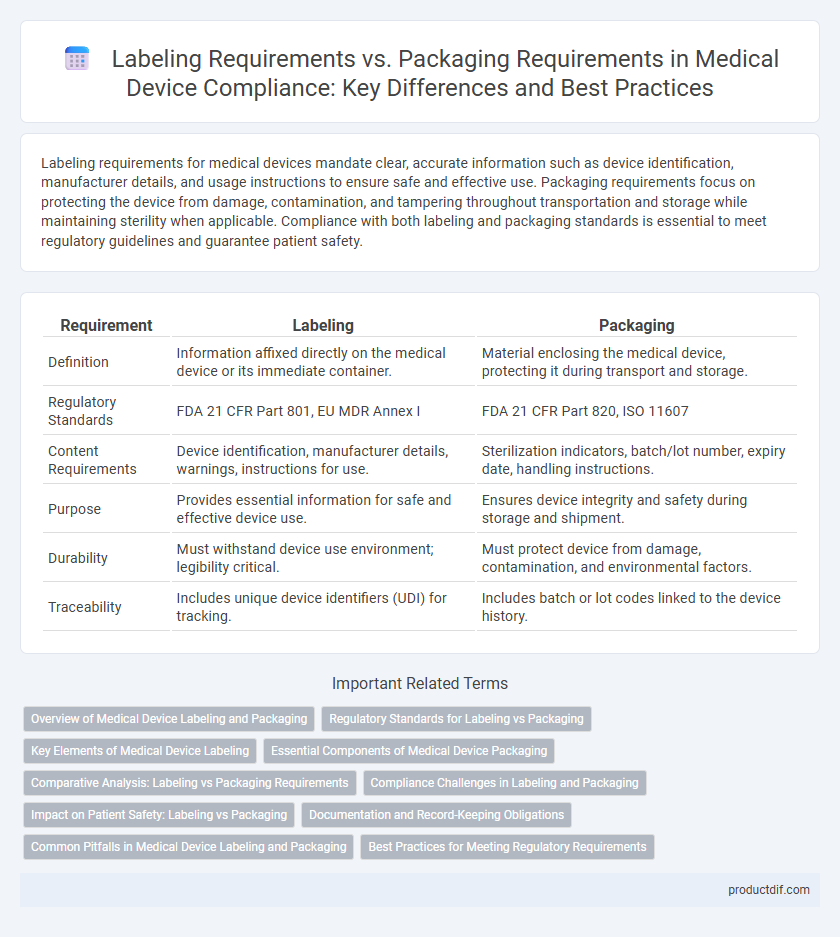

Labeling requirements for medical devices mandate clear, accurate information such as device identification, manufacturer details, and usage instructions to ensure safe and effective use. Packaging requirements focus on protecting the device from damage, contamination, and tampering throughout transportation and storage while maintaining sterility when applicable. Compliance with both labeling and packaging standards is essential to meet regulatory guidelines and guarantee patient safety.

Table of Comparison

| Requirement | Labeling | Packaging |

|---|---|---|

| Definition | Information affixed directly on the medical device or its immediate container. | Material enclosing the medical device, protecting it during transport and storage. |

| Regulatory Standards | FDA 21 CFR Part 801, EU MDR Annex I | FDA 21 CFR Part 820, ISO 11607 |

| Content Requirements | Device identification, manufacturer details, warnings, instructions for use. | Sterilization indicators, batch/lot number, expiry date, handling instructions. |

| Purpose | Provides essential information for safe and effective device use. | Ensures device integrity and safety during storage and shipment. |

| Durability | Must withstand device use environment; legibility critical. | Must protect device from damage, contamination, and environmental factors. |

| Traceability | Includes unique device identifiers (UDI) for tracking. | Includes batch or lot codes linked to the device history. |

Overview of Medical Device Labeling and Packaging

Medical device labeling requirements mandate clear, accurate information on the device's intended use, safety warnings, manufacturer details, and regulatory compliance, ensuring traceability and user comprehension. Packaging requirements focus on protecting the device from contamination, damage, and environmental factors during storage and transportation while maintaining sterility for sterile devices. Both labeling and packaging must adhere to standards such as FDA 21 CFR Part 801 and ISO 13485 to guarantee patient safety and regulatory compliance.

Regulatory Standards for Labeling vs Packaging

Regulatory standards for medical device labeling mandate clear, durable, and accurate information including device identification, manufacturer details, lot numbers, and expiration dates to ensure patient safety and traceability. Packaging requirements emphasize the integrity and protection of the device, mandating sterile barriers, tamper-evident features, and compliance with material biocompatibility and transportation conditions. Both labeling and packaging must adhere to global standards such as FDA 21 CFR Part 801, EU MDR 2017/745, and ISO 13485 to meet legal obligations and facilitate market access.

Key Elements of Medical Device Labeling

Key elements of medical device labeling include device identification, manufacturer information, instructions for use, lot or serial number, and expiration date, ensuring clear communication of critical data for safe device operation. Labeling must comply with regulatory standards such as FDA 21 CFR Part 801 or EU MDR Annex I, providing traceability and risk mitigation by displaying unique device identifiers (UDIs). Packaging requirements focus on maintaining sterility and integrity during transportation, but labeling distinctly emphasizes user guidance and legal information to support proper device handling and post-market surveillance.

Essential Components of Medical Device Packaging

Essential components of medical device packaging include labeling, which provides critical information such as device identification, instructions for use, lot or serial numbers, and regulatory symbols required by standards like FDA 21 CFR Part 820 and ISO 13485. Packaging requirements focus on maintaining sterility, protecting the device from contamination and physical damage during transportation and storage, and facilitating ease of use for healthcare providers. Both labeling and packaging must comply with risk management principles outlined in ISO 14971 to ensure patient safety and device performance throughout the product lifecycle.

Comparative Analysis: Labeling vs Packaging Requirements

Labeling requirements for medical devices mandate clear, durable information on product identification, usage instructions, warnings, and regulatory compliance symbols to ensure patient safety and traceability. Packaging requirements emphasize protection from contamination, physical damage, and environmental factors throughout storage and transport, often incorporating tamper-evident features and sterilization compatibility. Comparative analysis reveals that while labeling focuses on communication of critical product data, packaging prioritizes maintaining device integrity, both governed by strict standards such as FDA 21 CFR Part 820 and ISO 13485 to ensure overall device efficacy and regulatory adherence.

Compliance Challenges in Labeling and Packaging

Labeling requirements in medical devices demand precise information such as device identification, manufacturer details, and regulatory symbols to ensure patient safety and traceability. Packaging requirements focus on maintaining device sterility, protection during transportation, and tamper evidence, often involving specific materials and design standards. Compliance challenges arise from the need to align with diverse international regulations like FDA 21 CFR Part 820 and EU MDR, where discrepancies in labeling languages, font sizes, and packaging integrity tests often lead to product recalls and delayed market approval.

Impact on Patient Safety: Labeling vs Packaging

Labeling requirements ensure critical information such as dosage, expiration dates, and usage instructions are clearly communicated, directly reducing the risk of medication errors and enhancing patient safety. Packaging requirements focus on protecting the device from contamination, damage, and tampering, maintaining its sterility and functionality until use. Both labeling and packaging synergistically contribute to patient safety by preventing misuse and ensuring the integrity of medical devices throughout their lifecycle.

Documentation and Record-Keeping Obligations

Labeling requirements for medical devices mandate detailed documentation of label content, including symbols, instructions, and lot numbers, ensuring traceability and regulatory compliance. Packaging requirements emphasize maintaining records of packaging materials, sterilization processes, and integrity tests to guarantee product safety and effectiveness. Comprehensive record-keeping integrates both labeling and packaging data to support audits, incident investigations, and product recalls.

Common Pitfalls in Medical Device Labeling and Packaging

Common pitfalls in medical device labeling and packaging include inconsistent information between labels and packaging materials, leading to confusion or errors during device use. Failure to comply with regulatory standards such as FDA's 21 CFR Part 801 and EU MDR labeling requirements can result in non-compliance penalties and product recalls. Inadequate label durability and improper packaging that compromises sterility or device integrity are frequent issues that negatively impact patient safety and device performance.

Best Practices for Meeting Regulatory Requirements

Medical device labeling requirements emphasize clear, accurate, and durable information including device identification, intended use, and safety warnings to ensure compliance with regulatory standards such as FDA 21 CFR Part 801 and EU MDR Article 12. Packaging requirements focus on maintaining device integrity, sterility, and traceability through tamper-evident seals, proper sterilization indicators, and material selection that meets ISO 11607 standards. Best practices involve integrating labeling and packaging processes early in product development, conducting thorough verification and validation, and maintaining comprehensive documentation to streamline regulatory submissions and audits.

Labeling requirements vs Packaging requirements Infographic

productdif.com

productdif.com