Through-hole technology involves inserting component leads into drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, providing strong mechanical bonds ideal for high-stress applications. Surface-mount technology (SMT) attaches components directly onto the PCB surface, allowing for smaller, denser circuit designs and automated assembly processes. Understanding the trade-offs between through-hole and surface-mount methods is crucial for optimizing electronic device performance and manufacturing efficiency.

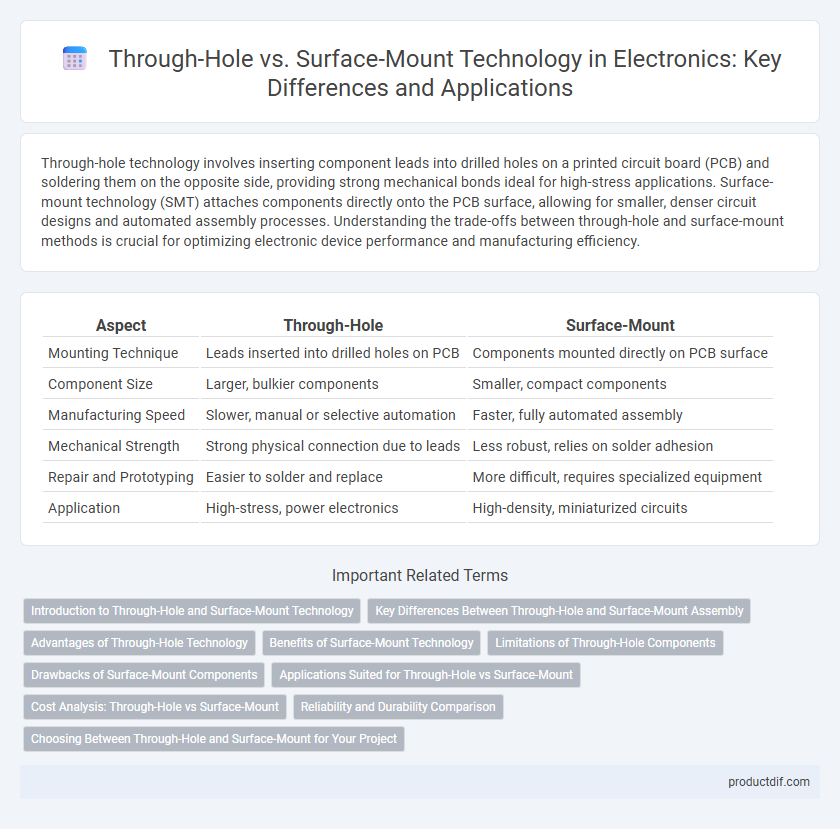

Table of Comparison

| Aspect | Through-Hole | Surface-Mount |

|---|---|---|

| Mounting Technique | Leads inserted into drilled holes on PCB | Components mounted directly on PCB surface |

| Component Size | Larger, bulkier components | Smaller, compact components |

| Manufacturing Speed | Slower, manual or selective automation | Faster, fully automated assembly |

| Mechanical Strength | Strong physical connection due to leads | Less robust, relies on solder adhesion |

| Repair and Prototyping | Easier to solder and replace | More difficult, requires specialized equipment |

| Application | High-stress, power electronics | High-density, miniaturized circuits |

Introduction to Through-Hole and Surface-Mount Technology

Through-Hole Technology involves inserting electronic component leads into pre-drilled holes on a printed circuit board (PCB), offering strong mechanical bonds suitable for components requiring high durability or power handling. Surface-Mount Technology (SMT) attaches components directly onto the surface of the PCB without the need for holes, enabling higher component density and improved automated assembly efficiency. Both technologies serve distinct purposes in electronics manufacturing, with Through-Hole favored for robust connections and SMT preferred for compact, high-volume applications.

Key Differences Between Through-Hole and Surface-Mount Assembly

Through-hole assembly involves mounting electronic components with leads inserted into drilled holes on a printed circuit board (PCB), offering strong mechanical bonds ideal for heavy or high-stress applications. Surface-mount assembly places components directly onto the PCB surface without holes, enabling higher component density and faster automated production suitable for compact, high-speed devices. The primary differences lie in assembly technique, mechanical strength, component size, and suitability for mass production versus prototyping or rugged use.

Advantages of Through-Hole Technology

Through-hole technology offers superior mechanical strength due to components being soldered directly through the PCB, making it ideal for high-stress applications and connectors. It provides easier prototyping and testing since components can be manually inserted and replaced without specialized equipment. This method enhances reliability in environments with high vibration or thermal cycling compared to surface-mount technology.

Benefits of Surface-Mount Technology

Surface-Mount Technology (SMT) offers significant benefits such as reduced size and weight of electronic assemblies, allowing for higher component density and more compact designs. SMT components typically provide better electrical performance with shorter lead lengths, resulting in lower parasitic inductance and capacitance. Enhanced automation and faster production rates also contribute to cost efficiency and improved manufacturing consistency in electronics manufacturing.

Limitations of Through-Hole Components

Through-hole components face limitations such as larger size and higher profile, making them less suitable for compact and high-density circuit designs. Their installation requires drilling holes on the PCB, increasing manufacturing complexity and cost compared to surface-mount technology (SMT). Additionally, through-hole assembly is slower and less compatible with automated production lines, restricting scalability for modern electronics manufacturing.

Drawbacks of Surface-Mount Components

Surface-mount components often face limitations in handling high power dissipation compared to through-hole parts, impacting thermal management on densely packed PCBs. Their smaller size and fragile leads make manual soldering and repair more challenging, increasing manufacturing complexity and costs. Additionally, surface-mount devices may exhibit lower mechanical strength under physical stress, which can reduce reliability in demanding environments.

Applications Suited for Through-Hole vs Surface-Mount

Through-hole technology excels in applications requiring high mechanical strength, such as connectors, transformers, and components exposed to mechanical stress or frequent handling. Surface-mount technology (SMT) is ideal for high-density, compact designs found in smartphones, laptops, and wearables, enabling automated assembly and smaller PCB footprints. Power electronics and prototypes often utilize through-hole components for easier prototyping and heat dissipation, whereas mass-produced consumer electronics heavily rely on SMT for efficient manufacturing and miniaturization.

Cost Analysis: Through-Hole vs Surface-Mount

Through-hole components typically incur higher manufacturing costs due to more labor-intensive assembly and increased material usage from drilled PCB holes. Surface-mount technology (SMT) benefits from automated placement and smaller component sizes, leading to lower production costs and higher assembly efficiency. The cost-effectiveness of SMT makes it the preferred choice for high-volume electronics manufacturing, while through-hole remains viable for prototyping and designs requiring mechanical strength.

Reliability and Durability Comparison

Through-hole components generally offer superior mechanical strength due to their leads passing through the PCB, making them more reliable in high-stress environments. Surface-mount technology (SMT) provides enhanced electrical performance with smaller, lighter components but may be less durable under mechanical shock or vibration. Reliability in harsh conditions often favors through-hole mounting, while SMT excels in compact, high-density electronic designs.

Choosing Between Through-Hole and Surface-Mount for Your Project

Choosing between through-hole and surface-mount technology depends on factors such as mechanical strength, assembly method, and space constraints. Through-hole components offer superior durability and are ideal for high-stress or prototype applications, while surface-mount devices enable higher component density and automated production. Evaluating your project's size, complexity, and performance requirements ensures the most effective component mounting method.

Through-Hole vs Surface-Mount Infographic

productdif.com

productdif.com