A zero-ohm resistor functions as a simple wire link with standardized packaging, enabling automated PCB assembly and testing, while a jumper is a manual connection used for configuring circuits or debugging. Zero-ohm resistors provide reliable soldered connections with minimal resistance, suited for signal routing and circuit customization without impacting performance. Jumpers offer flexibility for changing circuit paths but require manual placement and are less suitable for automated manufacturing processes.

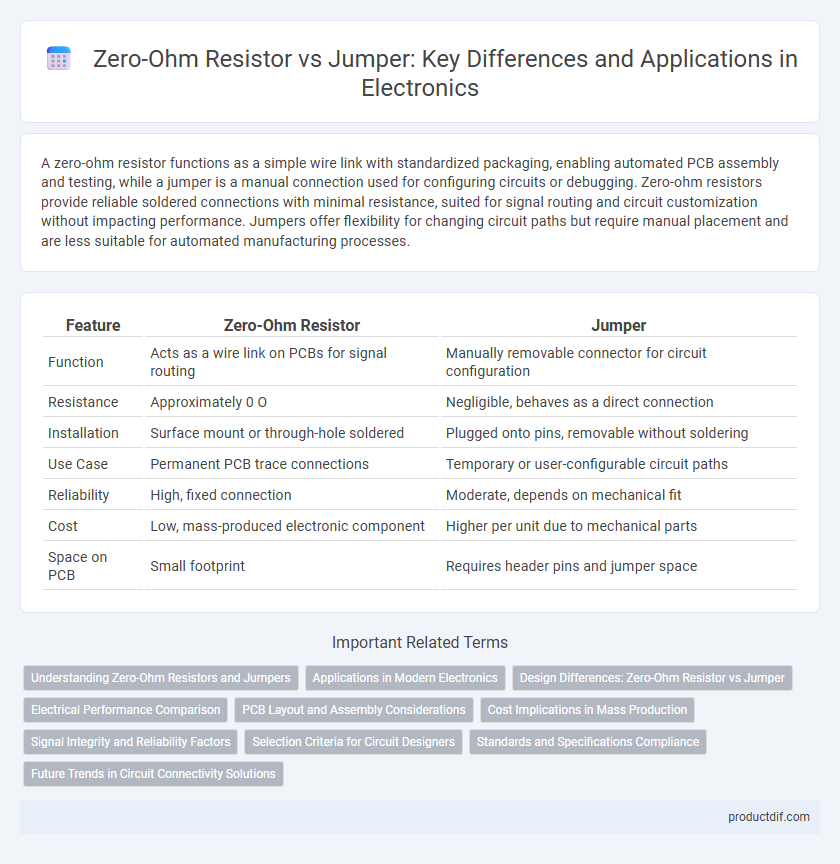

Table of Comparison

| Feature | Zero-Ohm Resistor | Jumper |

|---|---|---|

| Function | Acts as a wire link on PCBs for signal routing | Manually removable connector for circuit configuration |

| Resistance | Approximately 0 O | Negligible, behaves as a direct connection |

| Installation | Surface mount or through-hole soldered | Plugged onto pins, removable without soldering |

| Use Case | Permanent PCB trace connections | Temporary or user-configurable circuit paths |

| Reliability | High, fixed connection | Moderate, depends on mechanical fit |

| Cost | Low, mass-produced electronic component | Higher per unit due to mechanical parts |

| Space on PCB | Small footprint | Requires header pins and jumper space |

Understanding Zero-Ohm Resistors and Jumpers

Zero-ohm resistors and jumpers both serve as electrical connections on printed circuit boards, but zero-ohm resistors are standardized components marked like resistors, offering automated assembly compatibility and consistent mechanical stability. Jumpers are simple wire links or soldered bridges used for straightforward connectivity but may lack the precision and ease of automated placement provided by zero-ohm resistors. Understanding their differences aids in selecting appropriate solutions for circuit design, balancing reliability, manufacturing processes, and cost.

Applications in Modern Electronics

Zero-ohm resistors serve as convenient bridge components on printed circuit boards, enabling automated soldering processes and flexible circuit configurations without altering signal integrity. Jumpers provide manual or removable connections for configuring hardware settings, commonly found in legacy systems or prototype boards where easy circuit alterations are necessary. In modern electronics, zero-ohm resistors are preferred for streamlined manufacturing and compact designs, while jumpers are used selectively for user-defined or maintenance-accessible connections.

Design Differences: Zero-Ohm Resistor vs Jumper

Zero-ohm resistors are surface-mount components designed to fit standard resistor footprints, providing easy integration into automated PCB assembly processes, while jumpers are typically wire links or through-hole components used for manual or configurable connections. The zero-ohm resistor offers precise impedance control and consistent physical dimensions, which helps maintain signal integrity and circuit reliability in high-speed electronic designs. Jumpers, in contrast, offer flexible circuit reconfiguration but lack standardized sizing and can introduce variable parasitic inductance and resistance.

Electrical Performance Comparison

Zero-Ohm Resistors and jumpers both serve as conductive links on printed circuit boards, offering minimal resistance to current flow, typically in the milliohm range for zero-ohm resistors. Zero-Ohm Resistors provide standardized electrical characteristics with predictable parasitic inductance and capacitance, making them suitable for high-frequency applications, whereas jumpers, often simple wire links, may introduce higher and less predictable parasitic effects. The controlled resistance and enhanced reliability of zero-ohm resistors contribute to consistent signal integrity and improved performance in complex electronic circuits compared to traditional jumpers.

PCB Layout and Assembly Considerations

Zero-ohm resistors serve as convenient jumpers in PCB layouts, enabling configurable routing without altering the manufacturing process. They facilitate automated assembly by allowing pick-and-place machines to handle jumpers like standard components, reducing manual soldering errors and improving production efficiency. Choosing zero-ohm resistors over wire jumpers enhances signal integrity and maintains consistent impedance, critical for high-frequency circuit designs.

Cost Implications in Mass Production

Zero-Ohm resistors typically incur higher costs than jumpers in mass production due to their specific manufacturing standards and automated placement compatibility. Jumpers offer a more cost-effective solution by reducing material expenses and simplifying PCB assembly processes. Utilizing zero-ohm resistors can justify their expense when automated assembly lines prioritize component uniformity and placement precision.

Signal Integrity and Reliability Factors

Zero-ohm resistors offer superior signal integrity compared to jumpers by ensuring consistent impedance and reducing electromagnetic interference in high-frequency circuits. Their standardized packaging and solderability enhance reliability during automated PCB assembly, minimizing mechanical failures and connection issues common with manual jumper wires. Choosing zero-ohm resistors improves circuit performance by maintaining optimal electrical characteristics and stable long-term connections.

Selection Criteria for Circuit Designers

Zero-ohm resistors are preferred for automated PCB assembly due to their compatibility with pick-and-place machines, whereas jumpers require manual installation, increasing labor costs. Circuit designers select zero-ohm resistors when needing configurable circuit paths with minimal resistance and enhanced signal integrity. Jumper wires offer greater flexibility for prototyping or post-production modifications but may introduce parasitic inductance affecting high-frequency signal performance.

Standards and Specifications Compliance

Zero-ohm resistors and jumpers differ in standards and specifications compliance, with zero-ohm resistors adhering to IEC 60115 and ANSI/ESDA standards, ensuring defined electrical characteristics and reliability under specified conditions. Jumpers, typically non-standardized, are simple conductive links without strict compliance requirements, often used for manual configuration or testing. Utilizing zero-ohm resistors guarantees traceability and consistency in automated assembly processes, meeting industry norms for circuit integrity.

Future Trends in Circuit Connectivity Solutions

Zero-ohm resistors and jumpers remain fundamental in PCB design, but emerging trends favor integrated connectivity solutions with enhanced reliability and miniaturization. Advances in flexible electronics and smart interconnects are driving the shift towards zero-ohm resistors embedded within multilayer substrates, reducing manual assembly and improving signal integrity. Future circuit connectivity solutions will emphasize automation, robustness, and compatibility with high-frequency applications, positioning zero-ohm resistors and jumpers as part of more sophisticated modular connectivity systems.

Zero-Ohm Resistor vs Jumper Infographic

productdif.com

productdif.com