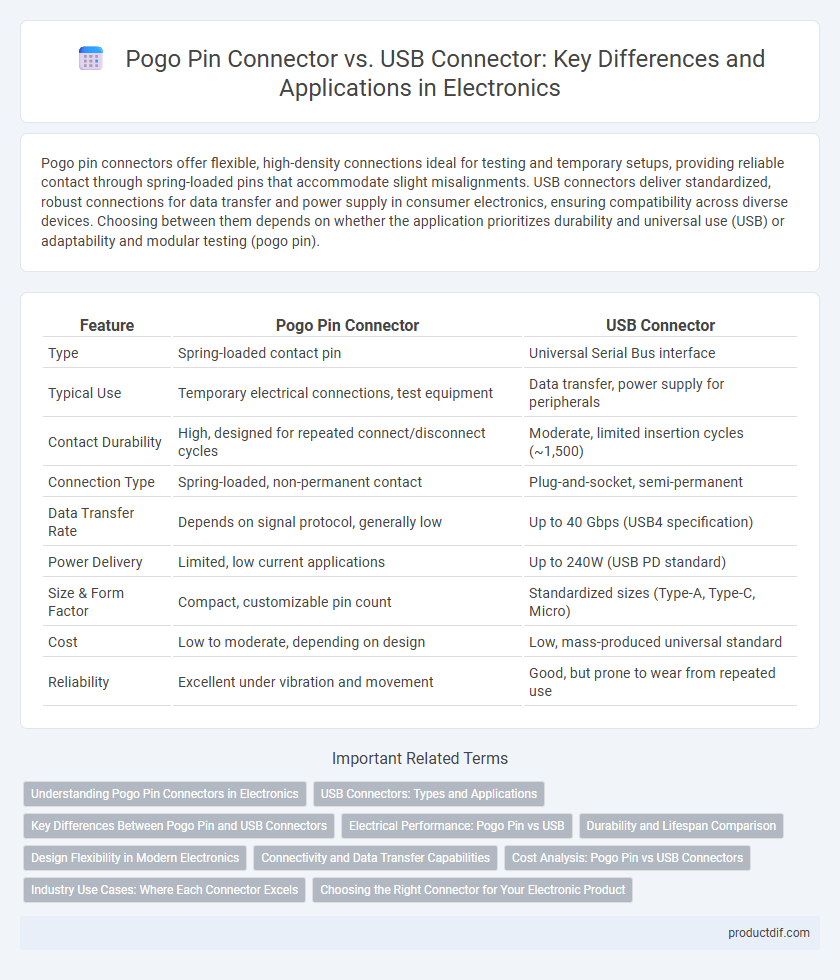

Pogo pin connectors offer flexible, high-density connections ideal for testing and temporary setups, providing reliable contact through spring-loaded pins that accommodate slight misalignments. USB connectors deliver standardized, robust connections for data transfer and power supply in consumer electronics, ensuring compatibility across diverse devices. Choosing between them depends on whether the application prioritizes durability and universal use (USB) or adaptability and modular testing (pogo pin).

Table of Comparison

| Feature | Pogo Pin Connector | USB Connector |

|---|---|---|

| Type | Spring-loaded contact pin | Universal Serial Bus interface |

| Typical Use | Temporary electrical connections, test equipment | Data transfer, power supply for peripherals |

| Contact Durability | High, designed for repeated connect/disconnect cycles | Moderate, limited insertion cycles (~1,500) |

| Connection Type | Spring-loaded, non-permanent contact | Plug-and-socket, semi-permanent |

| Data Transfer Rate | Depends on signal protocol, generally low | Up to 40 Gbps (USB4 specification) |

| Power Delivery | Limited, low current applications | Up to 240W (USB PD standard) |

| Size & Form Factor | Compact, customizable pin count | Standardized sizes (Type-A, Type-C, Micro) |

| Cost | Low to moderate, depending on design | Low, mass-produced universal standard |

| Reliability | Excellent under vibration and movement | Good, but prone to wear from repeated use |

Understanding Pogo Pin Connectors in Electronics

Pogo pin connectors provide reliable, spring-loaded contact points that ensure a secure electrical connection in compact and high-vibration electronic devices. Unlike USB connectors, pogo pins offer flexibility for custom pin configurations and durable performance in repeated mating cycles, making them ideal for testing and modular applications. Their small size and pressure-based contact mechanism enable precise signal transmission in handheld gadgets, wearables, and industrial equipment.

USB Connectors: Types and Applications

USB connectors encompass several types including USB-A, USB-B, USB-C, Micro-USB, and Mini-USB, each designed for specific applications ranging from data transfer and charging in consumer electronics to industrial and automotive uses. USB-C has become the industry standard due to its reversible design, high data transfer rates, and versatility in powering devices across laptops, smartphones, and peripherals. Applications of USB connectors extend to external storage, audio interfaces, docking stations, and fast charging, making them essential for modern connectivity solutions.

Key Differences Between Pogo Pin and USB Connectors

Pogo pin connectors feature spring-loaded pins that ensure reliable, low-profile connections primarily for intermittent electrical contacts in testing and docking applications, whereas USB connectors provide standardized interfaces for data transfer and power supply with fixed contact layouts. Pogo pins offer flexibility and durability with high cycle life suited for compact devices, while USB connectors emphasize universal compatibility and faster data transmission standards such as USB 3.1 or USB-C. Unlike the rigid USB connectors, pogo pins allow for slight misalignment during mating, making them ideal for modular electronics and quick-release connections.

Electrical Performance: Pogo Pin vs USB

Pogo pin connectors offer superior electrical performance in applications requiring high-frequency signal transmission and reliable contact under mechanical stress due to their spring-loaded design, which ensures consistent contact force and low resistance. USB connectors provide standardized electrical specifications suitable for power and data transfer but may face signal integrity issues in environments with vibration or frequent mating cycles. For high-precision electronics, pogo pins deliver enhanced durability and stable conductivity, whereas USB connectors excel in universal compatibility and ease of use.

Durability and Lifespan Comparison

Pogo pin connectors feature spring-loaded contacts designed to withstand over 100,000 mating cycles, offering superior durability in high-cycle applications compared to standard USB connectors, which typically endure around 1,500 to 10,000 insertion cycles before wear. The robust mechanical design of pogo pins resists corrosion and debris more effectively, enhancing lifespan in industrial and rugged environments. USB connectors, while widely used for data transfer and charging, are prone to contact deformation and oxidation, limiting their long-term reliability under frequent use.

Design Flexibility in Modern Electronics

Pogo pin connectors offer superior design flexibility in modern electronics by enabling compact, high-density interconnects suitable for irregular or customized device geometries, unlike USB connectors that require fixed port dimensions and alignment. Their spring-loaded pins accommodate mechanical tolerances and vibration, making them ideal for wearable devices, modular components, and docking stations where space constraints and durability are critical. USB connectors, while standardized and widely supported, often limit innovative form factors due to their rigid physical design and orientation requirements.

Connectivity and Data Transfer Capabilities

Pogo pin connectors provide reliable spring-loaded contact points ideal for quick and repeated connections in compact devices, ensuring consistent signal integrity in high-vibration environments. USB connectors support standardized interfaces enabling high-speed data transfer rates up to 40 Gbps with USB4, suitable for broad compatibility across computers, peripherals, and mobile devices. While pogo pins excel in mechanical durability and flexible form factors, USB connectors deliver superior bandwidth and universal connectivity for demanding data transmission needs.

Cost Analysis: Pogo Pin vs USB Connectors

Pogo pin connectors typically incur higher manufacturing costs compared to USB connectors due to their precision spring-loaded contacts and specialized materials, impacting overall production expenses. USB connectors benefit from widespread manufacturing scale and standardized designs, significantly reducing unit costs and simplifying supply chain logistics. When evaluating cost-effectiveness for mass production, USB connectors generally offer a lower total cost of ownership compared to pogo pin connectors despite the latter's advantages in compactness and reliable electrical contact.

Industry Use Cases: Where Each Connector Excels

Pogo pin connectors excel in industries requiring high-density, reliable spring-loaded contacts for testing and temporary connections, such as wearable devices and PCB testing fixtures. USB connectors dominate in consumer electronics and data transfer applications, offering standardized interfaces for power delivery and communication in devices like smartphones, computers, and peripherals. Industrial automation and medical devices leverage pogo pins for durable, frequent mating cycles, whereas USB connectors are preferred for universal compatibility and ease of use in everyday electronics.

Choosing the Right Connector for Your Electronic Product

Pogo pin connectors offer reliable spring-loaded contact ideal for compact and removable electronic devices, ensuring secure and consistent electrical connection under mechanical stress. USB connectors provide standardized data transfer and power delivery, supporting compatibility across a wide range of devices and enabling high-speed communication protocols like USB 3.0 and USB-C. Selecting the right connector depends on the application's requirements for durability, signal integrity, physical space, and ease of user interface integration.

Pogo Pin Connector vs USB Connector Infographic

productdif.com

productdif.com