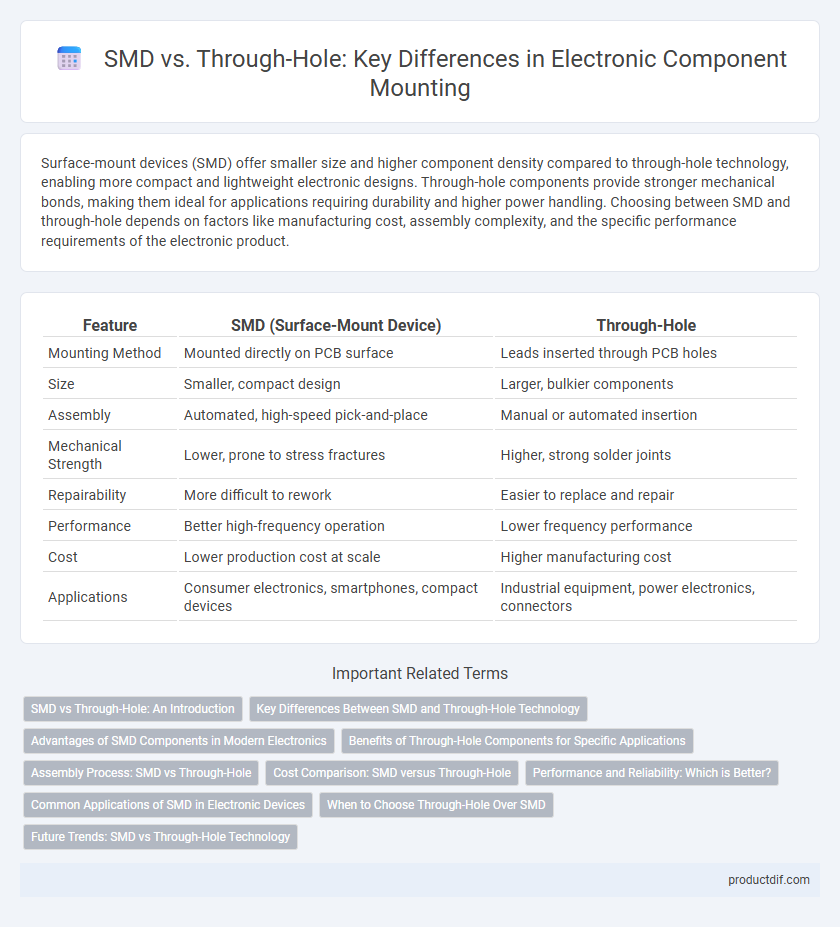

Surface-mount devices (SMD) offer smaller size and higher component density compared to through-hole technology, enabling more compact and lightweight electronic designs. Through-hole components provide stronger mechanical bonds, making them ideal for applications requiring durability and higher power handling. Choosing between SMD and through-hole depends on factors like manufacturing cost, assembly complexity, and the specific performance requirements of the electronic product.

Table of Comparison

| Feature | SMD (Surface-Mount Device) | Through-Hole |

|---|---|---|

| Mounting Method | Mounted directly on PCB surface | Leads inserted through PCB holes |

| Size | Smaller, compact design | Larger, bulkier components |

| Assembly | Automated, high-speed pick-and-place | Manual or automated insertion |

| Mechanical Strength | Lower, prone to stress fractures | Higher, strong solder joints |

| Repairability | More difficult to rework | Easier to replace and repair |

| Performance | Better high-frequency operation | Lower frequency performance |

| Cost | Lower production cost at scale | Higher manufacturing cost |

| Applications | Consumer electronics, smartphones, compact devices | Industrial equipment, power electronics, connectors |

SMD vs Through-Hole: An Introduction

Surface-Mount Devices (SMD) offer compact size and automated assembly advantages over traditional Through-Hole components, which require leads to pass through PCB holes. SMD technology supports higher circuit densities and improved performance in high-frequency applications, while Through-Hole components provide superior mechanical strength for heavy or high-stress connectors. Choosing between SMD and Through-Hole depends on factors such as manufacturing process, application requirements, and cost considerations.

Key Differences Between SMD and Through-Hole Technology

Surface-mount device (SMD) technology involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), whereas through-hole technology requires leads to be inserted into drilled holes and soldered on the opposite side. SMD components are generally smaller, enabling higher component density and more compact designs compared to the bulkier through-hole components which offer stronger mechanical bonds suited for high-stress environments. SMD assembly supports automated manufacturing processes leading to faster production and lower costs, while through-hole assembly often involves manual soldering, providing better durability for components subjected to physical stress or heat.

Advantages of SMD Components in Modern Electronics

Surface-Mount Device (SMD) components offer superior advantages in modern electronics due to their smaller size, which enables higher circuit density and miniaturization of devices. They provide better electrical performance with reduced parasitic inductance and capacitance, enhancing circuit speed and reliability. SMD technology also supports automated manufacturing processes, leading to faster production rates and lower assembly costs compared to traditional through-hole components.

Benefits of Through-Hole Components for Specific Applications

Through-hole components offer superior mechanical strength and durability, making them ideal for high-stress environments such as automotive and industrial electronics. Their robust leads facilitate easier prototyping and manual soldering, which is beneficial for low-volume production and repair work. Through-hole technology also provides better performance in high-frequency and high-voltage applications due to reduced parasitic capacitance and inductance.

Assembly Process: SMD vs Through-Hole

Surface Mount Device (SMD) assembly utilizes automated pick-and-place machines for precise component placement on printed circuit boards (PCBs), enhancing speed and efficiency compared to the manual or wave soldering processes often required for Through-Hole components. Through-Hole assembly involves inserting component leads through PCB holes followed by soldering, which provides stronger mechanical bonds ideal for high-stress environments but results in longer production times. The SMD process supports higher component density and miniaturization, making it preferable for modern, compact electronics manufacturing.

Cost Comparison: SMD versus Through-Hole

Surface Mount Devices (SMD) offer a cost advantage over Through-Hole components due to automated assembly processes that reduce labor expenses and increase production speed. Through-Hole components typically incur higher manufacturing costs because of manual insertion and drilling requirements on printed circuit boards (PCBs). SMD technology also minimizes material usage and PCB size, contributing to overall cost efficiency in modern electronics manufacturing.

Performance and Reliability: Which is Better?

Surface Mount Devices (SMD) offer superior performance with higher-frequency operation and reduced parasitic inductance compared to Through-Hole components. SMDs enhance reliability by enabling automated assembly processes that minimize solder joint defects and improve thermal performance. However, Through-Hole components provide stronger mechanical bonds, making them preferable for high-stress environments despite their lower frequency efficiency.

Common Applications of SMD in Electronic Devices

Surface-Mount Devices (SMD) are extensively used in modern electronic devices due to their compact size and suitability for automated assembly processes. Common applications include smartphones, laptops, and wearable technology where space-saving and high-density circuit boards are critical. SMD components also dominate in consumer electronics, automotive systems, and IoT devices, enabling enhanced performance and miniaturization.

When to Choose Through-Hole Over SMD

Through-hole technology is preferred over SMD when mechanical strength and durability are critical, such as in connectors, heavy components, or high-stress environments. It provides superior solder joint reliability and is ideal for prototyping or low-volume production where ease of manual assembly is necessary. Additionally, through-hole components are better suited for applications requiring high power dissipation due to their larger size and better heat management.

Future Trends: SMD vs Through-Hole Technology

Surface Mount Device (SMD) technology is poised to dominate future electronics manufacturing due to its smaller size, higher component density, and compatibility with automated assembly processes. Through-Hole technology, while offering superior mechanical strength and ease of prototyping, is increasingly limited to specialized applications such as high-reliability or high-power devices. Advances in SMD materials and precision placement techniques continue to expand its suitability, driving widespread adoption in consumer electronics, automotive systems, and IoT devices.

SMD vs Through-Hole Infographic

productdif.com

productdif.com