EMI shielding primarily protects electronic devices from electromagnetic interference caused by external electromagnetic fields, while RFI shielding targets radio frequency interference that disrupts wireless communication signals. Both shielding types use conductive materials to block or absorb unwanted signals, but EMI shielding often involves broader frequency ranges compared to the more specific frequencies addressed by RFI shielding. Effective design combines these techniques to ensure optimal performance and reliability of sensitive electronic equipment.

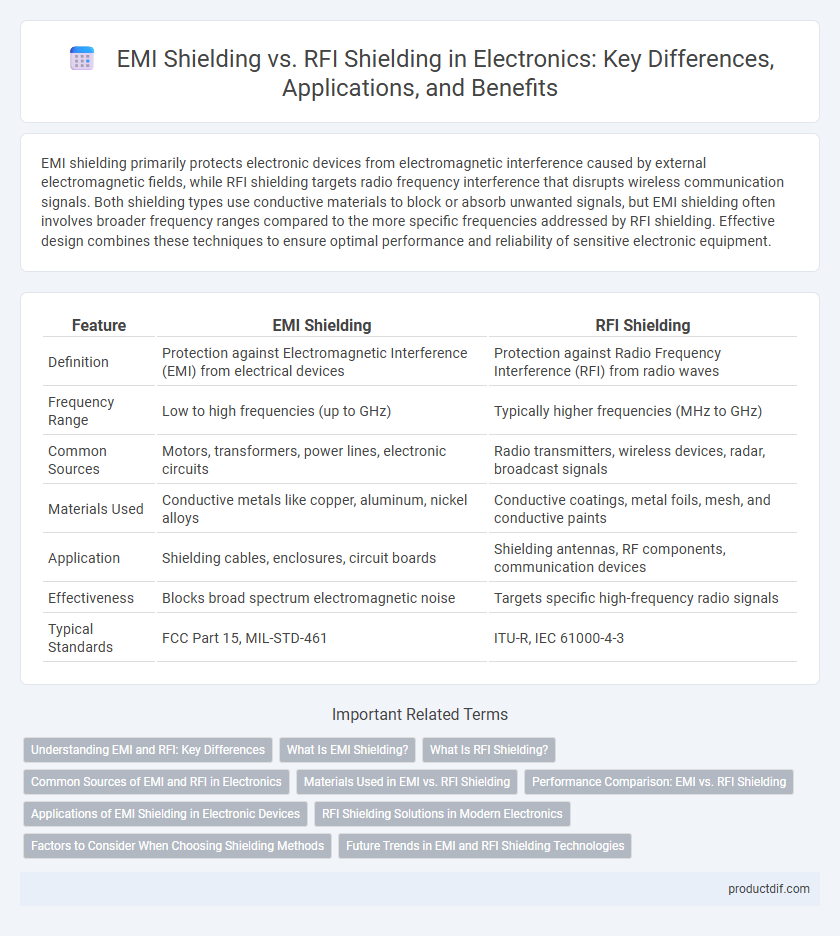

Table of Comparison

| Feature | EMI Shielding | RFI Shielding |

|---|---|---|

| Definition | Protection against Electromagnetic Interference (EMI) from electrical devices | Protection against Radio Frequency Interference (RFI) from radio waves |

| Frequency Range | Low to high frequencies (up to GHz) | Typically higher frequencies (MHz to GHz) |

| Common Sources | Motors, transformers, power lines, electronic circuits | Radio transmitters, wireless devices, radar, broadcast signals |

| Materials Used | Conductive metals like copper, aluminum, nickel alloys | Conductive coatings, metal foils, mesh, and conductive paints |

| Application | Shielding cables, enclosures, circuit boards | Shielding antennas, RF components, communication devices |

| Effectiveness | Blocks broad spectrum electromagnetic noise | Targets specific high-frequency radio signals |

| Typical Standards | FCC Part 15, MIL-STD-461 | ITU-R, IEC 61000-4-3 |

Understanding EMI and RFI: Key Differences

EMI shielding targets electromagnetic interference caused by electrical circuits, protecting devices from disruptions due to varying magnetic and electric fields. RFI shielding specifically addresses radio frequency interference, often from radio waves and wireless signals, which can degrade signal quality in communication systems. Differentiating these involves recognizing that EMI affects a broad spectrum of electromagnetic signals, while RFI is confined to higher-frequency radio waves, necessitating distinct shielding materials and techniques.

What Is EMI Shielding?

EMI shielding involves the use of conductive or magnetic materials to block or attenuate electromagnetic interference, protecting electronic circuits from unwanted electromagnetic waves. This shielding is essential in maintaining device performance and preventing signal disruption caused by external electromagnetic fields. Effective EMI shielding materials include metals like copper, aluminum, and specialized conductive coatings designed to reflect or absorb electromagnetic radiation.

What Is RFI Shielding?

RFI shielding refers to the process of blocking or reducing radio frequency interference, which typically originates from wireless communication devices and electronic circuits. It involves the use of conductive materials such as copper, aluminum, or specialized conductive coatings to create barriers that absorb or reflect electromagnetic waves in the radio frequency spectrum. Effective RFI shielding is critical in protecting sensitive electronic components from signal degradation, ensuring device performance and compliance with regulatory standards.

Common Sources of EMI and RFI in Electronics

Common sources of electromagnetic interference (EMI) in electronics include power lines, electric motors, and switching power supplies, which generate fluctuating magnetic fields disrupting device operation. Radio frequency interference (RFI) typically originates from wireless transmitters, radio stations, and cellular phones emitting radio waves that interfere with electronic circuits. Effective EMI and RFI shielding mechanisms target these sources by using conductive or magnetic materials to block or absorb unwanted electromagnetic energy, ensuring device functionality and signal integrity.

Materials Used in EMI vs. RFI Shielding

EMI shielding materials typically include metals like copper, aluminum, and nickel due to their high electrical conductivity and magnetic permeability, which effectively block electromagnetic interference. RFI shielding materials often use conductive fabrics, metal foils, and coatings such as silver or nickel-plated textiles that can attenuate radio frequency signals by reflecting or absorbing the interference. Selecting the appropriate shielding material depends on the frequency range and intensity of the electromagnetic or radio frequency signals involved.

Performance Comparison: EMI vs. RFI Shielding

EMI shielding primarily protects electronic devices from electromagnetic interference caused by external sources such as power lines and wireless signals, effectively blocking high-frequency magnetic and electric fields. RFI shielding targets radio frequency interference, reducing noise and signal degradation in communication devices by reflecting or absorbing radio waves within the 3 kHz to 300 GHz range. Performance comparison shows EMI shields excel in preventing disruptions in power electronics, while RFI shields are crucial for maintaining signal integrity in radio and wireless communication systems.

Applications of EMI Shielding in Electronic Devices

EMI shielding primarily protects electronic devices from electromagnetic interference that can disrupt circuit performance, making it essential in smartphones, computers, and medical equipment. It involves using conductive or magnetic materials to block or absorb undesired electromagnetic signals, ensuring signal integrity and device reliability. Applications include shielding power supplies, circuit boards, and connectors to prevent data loss and enhance device durability in complex electronic environments.

RFI Shielding Solutions in Modern Electronics

RFI shielding solutions in modern electronics employ conductive materials like copper, aluminum, and specialized polymers to block radio frequency interference that can degrade device performance. These solutions ensure signal integrity in high-frequency environments by effectively attenuating electromagnetic waves without compromising device functionality. Advanced coatings and multi-layer shielding designs optimize protection while maintaining thermal management and lightweight requirements essential for wearable and portable electronics.

Factors to Consider When Choosing Shielding Methods

EMI shielding effectiveness depends on factors like frequency range, shield material conductivity, and enclosure design, while RFI shielding focuses on preventing radio frequency interference with materials that reflect or absorb high-frequency signals. Consider the type of interference, operating frequency, environmental exposure, and cost when selecting shielding methods. Proper grounding, shield thickness, and compatibility with device form factors significantly impact overall performance in electronic applications.

Future Trends in EMI and RFI Shielding Technologies

Future trends in EMI and RFI shielding technologies emphasize the development of lightweight, flexible, and high-performance materials such as graphene and conductive polymers to enhance electromagnetic compatibility in compact electronics. Advances in nanotechnology enable the creation of multifunctional coatings that provide superior shielding effectiveness across broader frequency ranges while maintaining device miniaturization. Integration of AI-driven design tools accelerates the optimization of shielding structures to meet the growing demands of 5G, IoT, and wearable devices, ensuring robust protection against electromagnetic and radio frequency interference.

EMI Shielding vs RFI Shielding Infographic

productdif.com

productdif.com