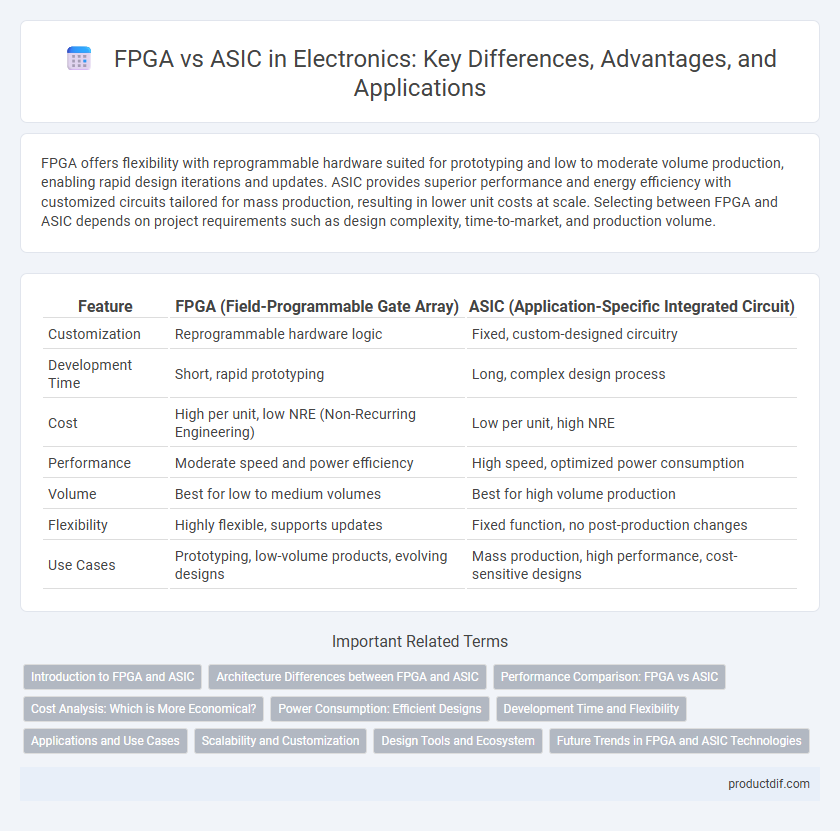

FPGA offers flexibility with reprogrammable hardware suited for prototyping and low to moderate volume production, enabling rapid design iterations and updates. ASIC provides superior performance and energy efficiency with customized circuits tailored for mass production, resulting in lower unit costs at scale. Selecting between FPGA and ASIC depends on project requirements such as design complexity, time-to-market, and production volume.

Table of Comparison

| Feature | FPGA (Field-Programmable Gate Array) | ASIC (Application-Specific Integrated Circuit) |

|---|---|---|

| Customization | Reprogrammable hardware logic | Fixed, custom-designed circuitry |

| Development Time | Short, rapid prototyping | Long, complex design process |

| Cost | High per unit, low NRE (Non-Recurring Engineering) | Low per unit, high NRE |

| Performance | Moderate speed and power efficiency | High speed, optimized power consumption |

| Volume | Best for low to medium volumes | Best for high volume production |

| Flexibility | Highly flexible, supports updates | Fixed function, no post-production changes |

| Use Cases | Prototyping, low-volume products, evolving designs | Mass production, high performance, cost-sensitive designs |

Introduction to FPGA and ASIC

Field-Programmable Gate Arrays (FPGAs) are integrated circuits designed for flexible hardware configuration post-manufacturing, enabling rapid prototyping and adaptability in electronics design. Application-Specific Integrated Circuits (ASICs) are custom-built chips tailored for specific tasks, offering higher performance and energy efficiency at the cost of longer development cycles and reduced flexibility. The choice between FPGA and ASIC depends on design requirements, production volume, and cost considerations in electronic systems.

Architecture Differences between FPGA and ASIC

FPGA architecture consists of an array of programmable logic blocks and interconnects, enabling flexible hardware configuration through lookup tables and flip-flops, while ASICs feature custom-designed logic circuits optimized for specific tasks, offering higher performance and lower power consumption. FPGA's reconfigurable nature supports rapid prototyping and iterative development, contrasting with ASIC's fixed architecture tailored for mass production and efficiency. The structural disparity impacts design complexity, manufacturing costs, and application suitability in electronics engineering.

Performance Comparison: FPGA vs ASIC

FPGA offers flexible reconfigurability with moderate performance, ideal for prototyping and low-volume production, while ASIC delivers superior speed, power efficiency, and optimized performance for high-volume, dedicated applications. ASIC's customized silicon architecture enables lower latency and higher throughput compared to FPGA's programmable logic blocks. Performance metrics such as clock frequency and power consumption consistently favor ASIC designs in demanding electronic systems.

Cost Analysis: Which is More Economical?

FPGA initial costs are lower due to the absence of non-recurring engineering (NRE) expenses, making them ideal for prototype development and low-volume production. ASICs, while requiring substantial upfront NRE and tooling investments, offer lower per-unit costs and higher performance in mass production. For large-scale manufacturing, ASICs become more economical overall despite their initial costs, whereas FPGAs remain cost-effective for smaller production runs and flexible designs.

Power Consumption: Efficient Designs

FPGA designs typically consume more power than ASICs due to their flexible, programmable architecture, which results in less optimized circuitry. ASICs offer power-efficient solutions by implementing customized logic tailored for specific applications, reducing unnecessary switching activity. Advanced ASIC fabrication processes and power gating techniques further minimize power consumption compared to FPGAs, making ASICs ideal for energy-conscious electronics.

Development Time and Flexibility

FPGAs offer significantly shorter development times compared to ASICs due to their reprogrammable architecture, enabling rapid prototyping and iterative design changes without fabricating new hardware. ASICs require extensive design, verification, and manufacturing processes, resulting in longer development cycles but optimized performance for mass production. The inherent flexibility of FPGAs allows engineers to update functionality even after deployment, while ASICs provide fixed functionality optimized for specific applications.

Applications and Use Cases

FPGAs excel in prototyping, low to medium volume production, and applications requiring reconfigurability, such as telecommunications, aerospace, and defense systems. ASICs are preferred for high-volume production due to cost efficiency and superior performance in consumer electronics, automotive systems, and specialized computing tasks. Both technologies address distinct market needs, with FPGAs offering flexibility and ASICs delivering optimized power and speed.

Scalability and Customization

FPGA offers superior scalability with its reprogrammable architecture, allowing designers to modify and optimize hardware functionalities post-deployment. ASIC provides unparalleled customization, tailored for specific applications with higher performance and lower power consumption but lacks the flexibility to adapt once fabricated. Scalability in ASICs is constrained by fixed design, whereas FPGAs excel in iterative development and deployment in diverse application environments.

Design Tools and Ecosystem

FPGA design tools offer high-level synthesis, extensive IP libraries, and robust debugging features, enabling rapid prototyping and iterative development within flexible ecosystems like Xilinx Vivado and Intel Quartus. ASIC design environments rely on specialized EDA tools such as Cadence and Synopsys, optimized for custom silicon layout, verification, and manufacturing readiness, providing comprehensive but complex workflows tailored to high-volume production. The FPGA ecosystem emphasizes adaptability and developer community support, while ASIC tooling integrates tightly with foundry processes and design-for-manufacturability standards.

Future Trends in FPGA and ASIC Technologies

Future trends in FPGA technologies emphasize increased integration of AI acceleration, enhanced power efficiency, and smaller process nodes like 5nm and 3nm to boost performance while reducing energy consumption. ASIC development is moving towards specialized, application-specific designs optimized for AI, 5G, and autonomous systems, leveraging advanced lithography techniques and heterogeneous integration. Both FPGA and ASIC advancements aim to support higher bandwidth, lower latency, and greater computational density in next-generation electronics.

FPGA vs ASIC Infographic

productdif.com

productdif.com