Ball Grid Array (BGA) offers superior thermal performance and higher pin density compared to Pin Grid Array (PGA), making it ideal for compact, high-performance electronics. BGA packages provide better electrical conductivity and reduced signal inductance due to their shorter connection paths, enhancing device reliability. In contrast, PGA sockets allow easier manual replacement and testing but are bulkier and less efficient for modern miniaturized circuit designs.

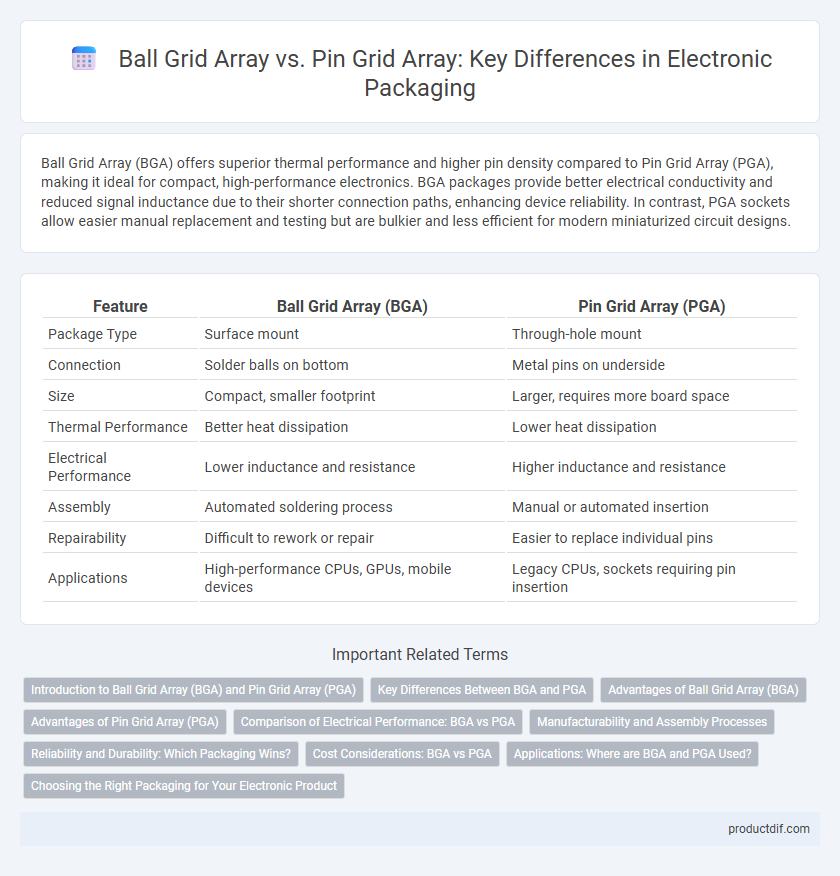

Table of Comparison

| Feature | Ball Grid Array (BGA) | Pin Grid Array (PGA) |

|---|---|---|

| Package Type | Surface mount | Through-hole mount |

| Connection | Solder balls on bottom | Metal pins on underside |

| Size | Compact, smaller footprint | Larger, requires more board space |

| Thermal Performance | Better heat dissipation | Lower heat dissipation |

| Electrical Performance | Lower inductance and resistance | Higher inductance and resistance |

| Assembly | Automated soldering process | Manual or automated insertion |

| Repairability | Difficult to rework or repair | Easier to replace individual pins |

| Applications | High-performance CPUs, GPUs, mobile devices | Legacy CPUs, sockets requiring pin insertion |

Introduction to Ball Grid Array (BGA) and Pin Grid Array (PGA)

Ball Grid Array (BGA) is a surface-mount packaging technology that uses an array of solder balls on the underside of the chip for electrical connections, enhancing thermal performance and reducing package size. Pin Grid Array (PGA), by contrast, features pins arranged in a grid pattern on the underside of the package that are inserted into corresponding socket holes on a printed circuit board (PCB), allowing easy replacement and robust mechanical connection. BGA is preferred for high-density, high-performance applications due to superior electrical characteristics, while PGA offers flexibility in prototyping and socketed CPU designs.

Key Differences Between BGA and PGA

Ball Grid Array (BGA) packages feature solder balls arranged in a grid on the underside, providing better thermal and electrical performance compared to Pin Grid Array (PGA), which uses pins protruding from the package. BGA offers higher pin density and improved signal integrity, reducing the risk of bent or broken pins common in PGA formats. Thermal dissipation in BGA is more efficient due to the direct contact of solder balls with the PCB, whereas PGA relies on through-hole mounting with lower heat transfer capabilities.

Advantages of Ball Grid Array (BGA)

Ball Grid Array (BGA) offers superior thermal performance and electrical conductivity due to its array of solder balls providing shorter connections and better heat dissipation compared to Pin Grid Array (PGA). BGA packages enable higher pin density, allowing more input/output connections in a compact footprint, which supports advanced and high-performance electronic devices. Enhanced mechanical stability and reduced risk of bent pins make BGA more reliable for modern applications requiring robust interconnections.

Advantages of Pin Grid Array (PGA)

Pin Grid Array (PGA) offers superior mechanical stability and ease of socket insertion compared to Ball Grid Array (BGA), facilitating hassle-free replacement and testing. PGA packages provide excellent heat dissipation due to the exposed pins and larger physical surface, enhancing thermal management in electronic devices. The distinct pin configuration in PGA also simplifies visual inspection and fault detection, improving reliability in manufacturing and maintenance processes.

Comparison of Electrical Performance: BGA vs PGA

Ball Grid Array (BGA) offers lower electrical resistance and inductance compared to Pin Grid Array (PGA) due to its shorter and more direct connection paths, enhancing signal integrity and reducing noise in high-frequency applications. BGA's solder balls provide better thermal conductivity and mechanical stability, which contribute to more consistent electrical performance during thermal cycling and mechanical stress. PGA's longer pins create higher parasitic inductance and capacitance, making it less suitable for high-speed, high-frequency circuits where electrical performance is critical.

Manufacturability and Assembly Processes

Ball Grid Array (BGA) packages offer superior manufacturability compared to Pin Grid Array (PGA) due to their smaller footprint and enhanced heat dissipation, which facilitates automated surface-mount assembly. BGA's solder balls provide more reliable electrical connections and reduce the risk of bent pins, improving assembly yield and long-term performance. In contrast, PGA requires careful pin alignment and manual insertion, increasing assembly complexity and potential for damage during handling.

Reliability and Durability: Which Packaging Wins?

Ball Grid Array (BGA) packages offer superior reliability and durability compared to Pin Grid Array (PGA) due to their solder balls that provide better mechanical strength and thermal performance. BGAs reduce the risk of bent pins and improve heat dissipation, enhancing long-term device stability in harsh environments. PGAs can be more susceptible to physical damage and fatigue from thermal cycling, making BGAs the preferred choice for high-reliability electronic applications.

Cost Considerations: BGA vs PGA

Ball Grid Array (BGA) packages generally offer lower manufacturing costs compared to Pin Grid Array (PGA) due to their simplified assembly process and reduced material usage. BGAs require fewer manual handling steps and provide better thermal performance, which can reduce overall system costs despite higher initial tooling expenses. PGA, while typically cheaper for low-volume or prototyping scenarios, incurs higher labor costs and complexity in soldering, making it less cost-effective for mass production.

Applications: Where are BGA and PGA Used?

Ball Grid Array (BGA) packages are primarily used in high-performance applications such as microprocessors, graphics cards, and mobile devices due to their excellent thermal and electrical performance. Pin Grid Array (PGA) packages are commonly found in desktop CPUs and socketed microprocessors where ease of installation and replacement is critical. BGA's compact footprint suits compact, high-density circuits, while PGA's socketed design enables greater flexibility in desktop platforms.

Choosing the Right Packaging for Your Electronic Product

Ball Grid Array (BGA) offers superior electrical performance and better heat dissipation compared to Pin Grid Array (PGA), making it ideal for high-density electronic products requiring compact design and reliable connections. PGA, with its easily replaceable pins and straightforward inspection, suits applications where maintenance and prototyping flexibility are priorities. Selecting the right packaging depends on balancing product complexity, manufacturing costs, and thermal management needs to optimize device performance and longevity.

Ball Grid Array vs Pin Grid Array Infographic

productdif.com

productdif.com