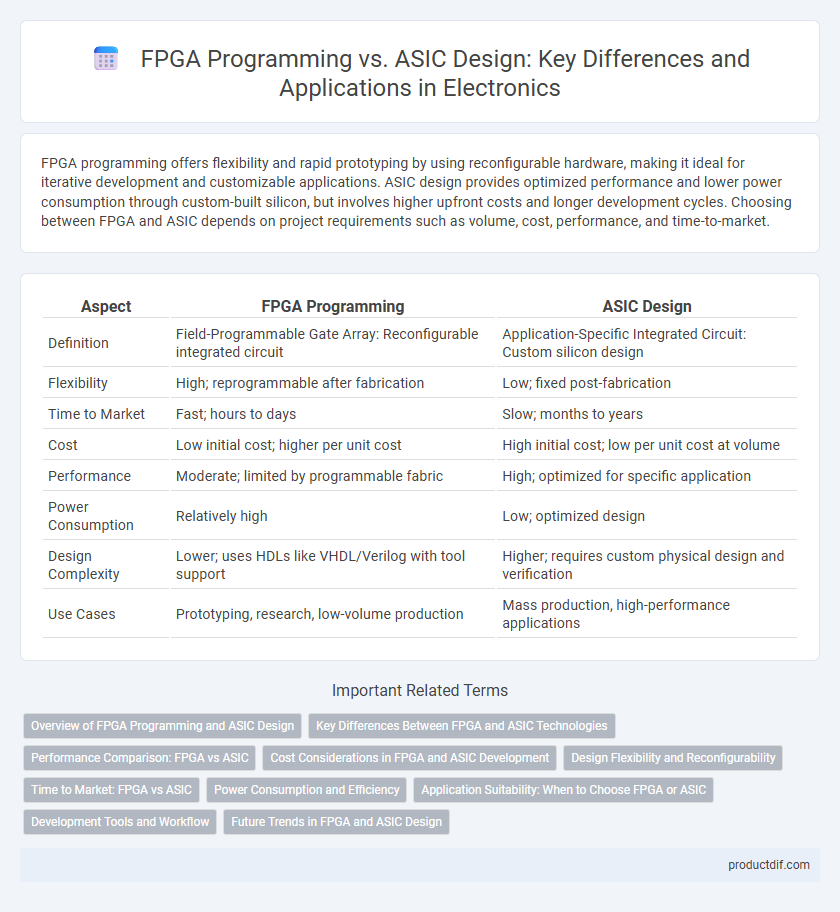

FPGA programming offers flexibility and rapid prototyping by using reconfigurable hardware, making it ideal for iterative development and customizable applications. ASIC design provides optimized performance and lower power consumption through custom-built silicon, but involves higher upfront costs and longer development cycles. Choosing between FPGA and ASIC depends on project requirements such as volume, cost, performance, and time-to-market.

Table of Comparison

| Aspect | FPGA Programming | ASIC Design |

|---|---|---|

| Definition | Field-Programmable Gate Array: Reconfigurable integrated circuit | Application-Specific Integrated Circuit: Custom silicon design |

| Flexibility | High; reprogrammable after fabrication | Low; fixed post-fabrication |

| Time to Market | Fast; hours to days | Slow; months to years |

| Cost | Low initial cost; higher per unit cost | High initial cost; low per unit cost at volume |

| Performance | Moderate; limited by programmable fabric | High; optimized for specific application |

| Power Consumption | Relatively high | Low; optimized design |

| Design Complexity | Lower; uses HDLs like VHDL/Verilog with tool support | Higher; requires custom physical design and verification |

| Use Cases | Prototyping, research, low-volume production | Mass production, high-performance applications |

Overview of FPGA Programming and ASIC Design

FPGA programming involves configuring a reprogrammable silicon chip to perform specific logic functions through hardware description languages like VHDL or Verilog, offering flexibility and rapid prototyping. ASIC design entails creating custom, fixed-function integrated circuits tailored for high performance, power efficiency, and volume production, requiring extensive development time and cost. While FPGA suits iterative development and low to medium volume applications, ASIC excels in large-scale deployment with optimized hardware performance.

Key Differences Between FPGA and ASIC Technologies

FPGA programming involves configuring a pre-fabricated chip to implement custom logic through hardware description languages, enabling rapid prototyping and reprogrammability, whereas ASIC design requires creating a fixed, application-specific integrated circuit optimized for performance and power efficiency. FPGAs offer flexibility and shorter development cycles, making them suitable for testing and low to mid-volume production, while ASICs provide superior performance, lower unit cost at scale, and are preferred for high-volume, optimized applications. The trade-offs include FPGA's higher per-unit cost and lower speed compared to ASICs, alongside ASICs' longer design times and lack of post-fabrication adaptability.

Performance Comparison: FPGA vs ASIC

ASIC designs offer superior performance compared to FPGA programming due to their tailored hardware architecture, enabling higher clock speeds and lower latency. FPGAs provide flexibility and rapid prototyping benefits but typically exhibit increased power consumption and slower processing speeds than ASICs. Performance-critical applications in telecommunications and high-frequency trading often prefer ASICs for their optimized throughput and energy efficiency.

Cost Considerations in FPGA and ASIC Development

FPGA programming offers lower initial development costs due to its reconfigurable nature and reduced manufacturing expenses, making it ideal for prototyping and low-volume production. ASIC design involves high non-recurring engineering (NRE) costs driven by custom silicon fabrication and mask creation, which become cost-effective only at large production volumes. Evaluating cost considerations requires balancing upfront investment with scalability, as FPGA suits flexible and iterative projects, whereas ASIC delivers optimized performance for mass production.

Design Flexibility and Reconfigurability

FPGA programming offers unparalleled design flexibility and reconfigurability, enabling developers to modify hardware logic post-deployment through reprogramming, which is ideal for prototyping and iterative development. In contrast, ASIC design delivers optimized performance and power efficiency for fixed-function applications but lacks the ability to adapt once fabricated, making it less suitable for evolving requirements. The inherent reconfigurability of FPGAs supports rapid innovation, while ASICs provide a cost-effective solution for high-volume production with stable design specifications.

Time to Market: FPGA vs ASIC

FPGA programming offers significantly faster time to market compared to ASIC design due to its reprogrammable hardware, allowing rapid prototyping and iterative development. ASIC design involves longer development cycles because of complex fabrication processes and extensive verification, which typically extend lead times by several months. Companies prioritize FPGA deployment to accelerate product launches and testing, reserving ASICs for high-volume, cost-sensitive applications where time constraints are less critical.

Power Consumption and Efficiency

FPGA programming offers flexibility and shorter development cycles but typically results in higher power consumption compared to ASIC design, which is optimized for power efficiency and performance. ASICs achieve superior energy efficiency by tailoring circuits to specific applications, reducing unnecessary logic and switching activity that increase power use in FPGAs. In power-sensitive electronics, ASICs provide a significant advantage due to their optimized silicon layout and lower static and dynamic power dissipation.

Application Suitability: When to Choose FPGA or ASIC

FPGA programming is ideal for prototyping, low to medium volume production, and applications requiring flexibility or frequent updates, such as custom signal processing and embedded system development. ASIC design suits high-volume production and applications demanding optimized power consumption, performance, and cost efficiency, including consumer electronics and telecommunications hardware. Choosing between FPGA and ASIC depends on factors like production scale, time-to-market, performance requirements, and development cost constraints.

Development Tools and Workflow

FPGA programming utilizes hardware description languages (HDLs) like VHDL or Verilog within integrated development environments (IDEs) such as Xilinx Vivado or Intel Quartus, enabling rapid prototyping and iterative debugging with real-time hardware reconfiguration. ASIC design requires complex electronic design automation (EDA) tools like Cadence Virtuoso or Synopsys Design Compiler, emphasizing synthesis, placement, routing, and timing closure for manufacturing-specific optimization. FPGA workflows prioritize flexibility and shorter development cycles, while ASIC workflows focus on precision, performance optimization, and higher upfront design verification.

Future Trends in FPGA and ASIC Design

Emerging trends in FPGA programming emphasize increased integration of AI accelerators and enhanced adaptability through partial reconfiguration, enabling real-time hardware updates and resource optimization. ASIC design advancements focus on scaling down to sub-3nm nodes and incorporating domain-specific architectures to maximize performance and energy efficiency for specialized applications. The convergence of FPGA flexibility with ASIC efficiency is driving hybrid design methodologies, fostering innovative solutions in high-performance computing and edge AI devices.

FPGA Programming vs ASIC Design Infographic

productdif.com

productdif.com