System in Package (SIP) integrates multiple integrated circuits (ICs) and passive components within a single package, offering flexibility in combining heterogeneous technologies and improving system performance through shorter interconnects. System on Chip (SOC) consolidates all electronic functions onto a single silicon die, enhancing power efficiency, reducing size, and optimizing data transfer speeds. SIP is ideal for modular designs with diverse components, while SOC suits applications demanding high integration and minimal footprint.

Table of Comparison

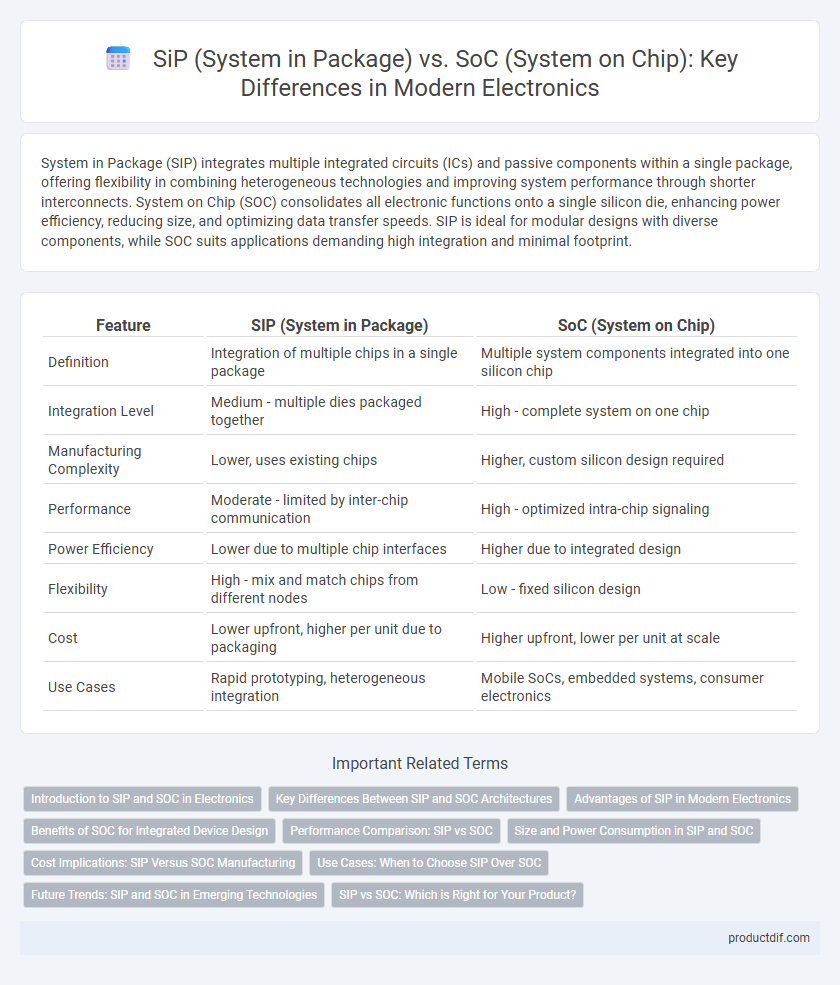

| Feature | SIP (System in Package) | SoC (System on Chip) |

|---|---|---|

| Definition | Integration of multiple chips in a single package | Multiple system components integrated into one silicon chip |

| Integration Level | Medium - multiple dies packaged together | High - complete system on one chip |

| Manufacturing Complexity | Lower, uses existing chips | Higher, custom silicon design required |

| Performance | Moderate - limited by inter-chip communication | High - optimized intra-chip signaling |

| Power Efficiency | Lower due to multiple chip interfaces | Higher due to integrated design |

| Flexibility | High - mix and match chips from different nodes | Low - fixed silicon design |

| Cost | Lower upfront, higher per unit due to packaging | Higher upfront, lower per unit at scale |

| Use Cases | Rapid prototyping, heterogeneous integration | Mobile SoCs, embedded systems, consumer electronics |

Introduction to SIP and SOC in Electronics

System in Package (SiP) integrates multiple integrated circuits and passive components into a single compact module, enhancing functionality and miniaturization in electronics. System on Chip (SoC) consolidates all critical system components, including the processor, memory, and peripherals, onto a single semiconductor substrate, offering improved performance and power efficiency. SiP provides design flexibility by combining heterogeneous technologies, while SoC delivers optimized integration for specific applications.

Key Differences Between SIP and SOC Architectures

SIP (System in Package) integrates multiple heterogeneous dies within a single package, enabling modular functionality and improved system flexibility compared to SOC (System on Chip), which consolidates all components on a single chip for optimized performance and reduced latency. SIP architecture supports diverse manufacturing processes for individual components, while SOC requires a unified fabrication technology, impacting cost and design complexity. Power consumption, scalability, and thermal management differ significantly, with SOC favoring efficiency and SIP offering adaptability in electronic design.

Advantages of SIP in Modern Electronics

System in Package (SiP) technology offers significant advantages in modern electronics by integrating multiple integrated circuits (ICs) and passive components into a single compact module, enhancing design flexibility and reducing form factor. SiP enables heterogeneous integration of diverse technologies such as analog, digital, RF, and MEMS components, improving overall device functionality and performance. The modular approach in SiP accelerates time-to-market and simplifies manufacturing processes compared to System on Chip (SoC) solutions, making it ideal for complex, multifunctional applications like IoT devices and wearables.

Benefits of SOC for Integrated Device Design

System on Chip (SoC) enhances integrated device design by consolidating multiple components such as CPU, memory, and peripherals onto a single silicon chip, resulting in reduced form factor and lower power consumption. SoC enables faster data processing and improved communication between integrated modules due to minimal interconnect distances. This integration supports higher performance and cost efficiency compared to System in Package (SiP) solutions, making SoC ideal for compact and high-speed electronics applications.

Performance Comparison: SIP vs SOC

System in Package (SIP) offers superior thermal management and modular scalability compared to System on Chip (SOC), enabling higher performance in complex applications with diverse component integration. SOC typically provides lower latency and power consumption by integrating multiple functions on a single silicon die, which enhances speed and efficiency for tightly coupled processing tasks. Performance in SIP excels when heterogeneous components require customization, while SOC outperforms in scenarios demanding high-speed interconnectivity and minimal footprint.

Size and Power Consumption in SIP and SOC

System in Package (SiP) integrates multiple chips into a single package, offering compact size but typically larger than System on Chip (SoC), which combines all components onto one silicon die, achieving the smallest footprint. SoCs generally provide lower power consumption due to optimized on-chip communication and reduced interconnect distances compared to SiP, where separate chips incur higher parasitic losses. The trade-off between SiP and SoC revolves around design flexibility versus ultimate miniaturization and energy efficiency in electronics.

Cost Implications: SIP Versus SOC Manufacturing

System in Package (SIP) manufacturing offers cost advantages by integrating multiple chips into a single module, reducing packaging and interconnect expenses. System on Chip (SOC) development entails higher initial design costs and longer time-to-market due to complex silicon integration but can lower per-unit costs at high volumes. SIP provides flexible cost scaling for mixed-technology solutions, while SOC benefits large-scale production through optimized semiconductor economies.

Use Cases: When to Choose SIP Over SOC

SIP (System in Package) is ideal for applications requiring heterogeneous integration of multiple semiconductor dies and components, such as RF modules, MEMS sensors, and power management units, enabling customized, compact solutions with enhanced performance. SOC (System on Chip) suits mass-produced consumer electronics demanding high integration and lower cost, such as smartphones and tablets, where uniformity and large-scale production are critical. Choose SIP over SOC when flexibility, multi-function integration, and rapid prototyping outweigh the benefits of complete on-chip integration and economies of scale.

Future Trends: SIP and SOC in Emerging Technologies

System in Package (SiP) and System on Chip (SoC) technologies are advancing rapidly to meet the demands of emerging electronics such as IoT devices, 5G communication, and AI-driven applications. SiP enables heterogeneous integration by combining multiple chips in a single package, enhancing modularity and flexibility for next-generation wearable and edge devices. SoC continues to evolve with improved performance and energy efficiency by integrating complex functionalities on a single chip, driving innovations in mobile computing and autonomous systems.

SIP vs SOC: Which is Right for Your Product?

System in Package (SiP) integrates multiple integrated circuits and passive components into a single package, offering flexibility in design and quicker time-to-market for complex electronics. System on Chip (SoC) embeds all required functions within a single silicon chip, delivering higher performance and lower power consumption ideal for compact, high-efficiency devices. Choosing between SiP and SoC depends on product requirements such as integration level, development cost, scalability, and power efficiency.

SIP (System in Package) vs SOC (System on Chip) Infographic

productdif.com

productdif.com