Stereolithography (SLA) offers superior surface finish and high-resolution detail by using a UV laser to cure liquid resin layer by layer, making it ideal for intricate electronic prototypes. Fused Deposition Modeling (FDM) utilizes thermoplastic filaments extruded through a heated nozzle, providing cost-effective and durable parts suitable for functional electronic housings. While SLA excels in precision, FDM delivers greater material versatility and faster production for larger components.

Table of Comparison

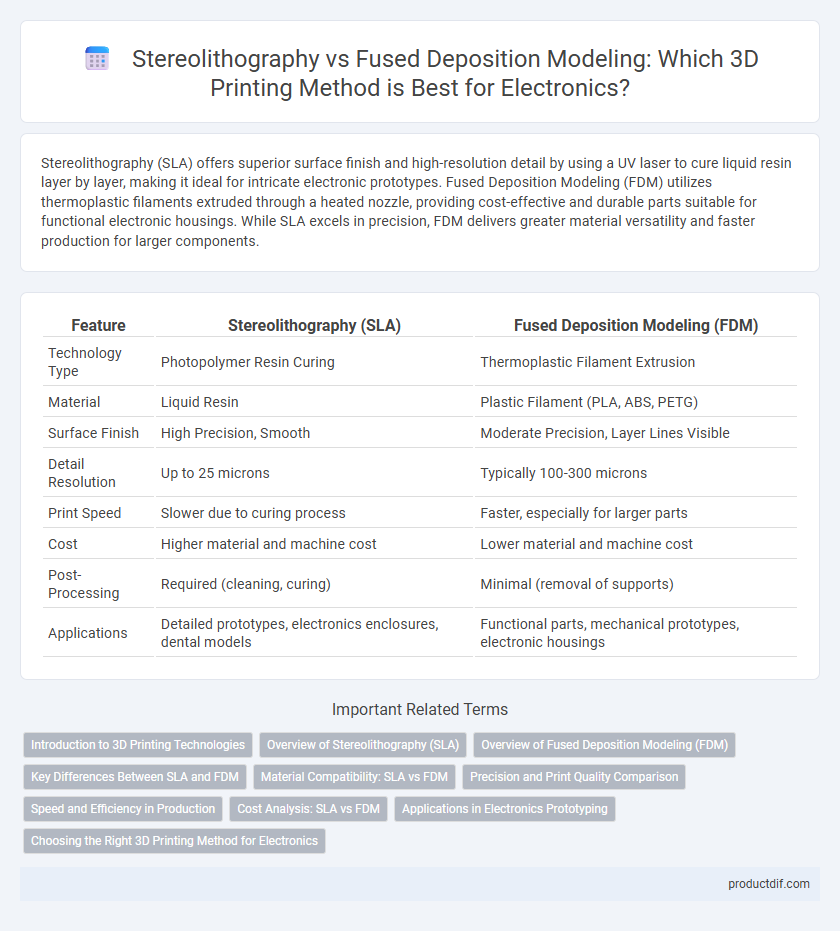

| Feature | Stereolithography (SLA) | Fused Deposition Modeling (FDM) |

|---|---|---|

| Technology Type | Photopolymer Resin Curing | Thermoplastic Filament Extrusion |

| Material | Liquid Resin | Plastic Filament (PLA, ABS, PETG) |

| Surface Finish | High Precision, Smooth | Moderate Precision, Layer Lines Visible |

| Detail Resolution | Up to 25 microns | Typically 100-300 microns |

| Print Speed | Slower due to curing process | Faster, especially for larger parts |

| Cost | Higher material and machine cost | Lower material and machine cost |

| Post-Processing | Required (cleaning, curing) | Minimal (removal of supports) |

| Applications | Detailed prototypes, electronics enclosures, dental models | Functional parts, mechanical prototypes, electronic housings |

Introduction to 3D Printing Technologies

Stereolithography (SLA) and Fused Deposition Modeling (FDM) are prominent 3D printing technologies used in electronics for rapid prototyping and component manufacturing. SLA utilizes a UV laser to cure liquid resin layer-by-layer, offering high precision and smooth surface finishes ideal for intricate electronic housing designs. FDM extrudes thermoplastic filament in layers, providing cost-effective and durable parts suited for functional prototypes and enclosures in electronic devices.

Overview of Stereolithography (SLA)

Stereolithography (SLA) is an advanced 3D printing technology that uses a laser to cure liquid resin into precise, solid structures layer by layer, delivering high-resolution prototypes with exceptional surface finish. SLA excels in producing intricate details and smooth surfaces, making it ideal for electronics applications requiring fine features, such as custom enclosures and functional components. Compared to Fused Deposition Modeling (FDM), SLA offers superior accuracy and finer layer thicknesses, enhancing the reliability and performance of electronic parts.

Overview of Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a widely used additive manufacturing technology that involves the extrusion of thermoplastic filaments layer by layer to build 3D objects. FDM excels in producing durable prototypes and functional parts with materials such as ABS, PLA, and PETG, offering cost-effective and scalable fabrication. This technique is favored in electronics for creating custom enclosures, brackets, and mechanical components due to its precision and material versatility.

Key Differences Between SLA and FDM

Stereolithography (SLA) employs a laser to cure liquid resin layer-by-layer, producing high-resolution, smooth-surface prototypes with intricate details, while Fused Deposition Modeling (FDM) uses thermoplastic filaments melted and extruded through a nozzle, resulting in more durable but lower resolution parts. SLA excels in precision and surface finish, making it ideal for complex electronic enclosures and fine features, whereas FDM offers cost-effective, faster production suited for functional testing and larger components. Key differences include material types, printing speed, surface quality, and overall part accuracy, with SLA favored for detailed visuals and FDM preferred for durability and prototyping efficiency.

Material Compatibility: SLA vs FDM

Stereolithography (SLA) excels in producing highly detailed electronic prototypes using photopolymer resins with excellent surface finish and dimensional accuracy, making it ideal for intricate circuit housings and microcomponents. Fused Deposition Modeling (FDM) supports a broader range of thermoplastics like ABS, PLA, and PETG, offering superior mechanical strength and thermal stability suited for durable electronic enclosures and functional parts. Material compatibility in SLA emphasizes precision and fine detail through liquid resins, while FDM prioritizes versatility and robustness using filament-based thermoplastics.

Precision and Print Quality Comparison

Stereolithography (SLA) offers superior precision and finer print quality due to its laser-based curing process, achieving layer resolutions as low as 25 microns. Fused Deposition Modeling (FDM) typically produces coarser details with layer heights around 100-300 microns, which can result in visible layer lines and less intricate features. SLA is preferred for applications requiring high-detail electronic enclosures and prototypes where surface finish and dimensional accuracy are critical.

Speed and Efficiency in Production

Stereolithography (SLA) offers high precision but generally operates slower than Fused Deposition Modeling (FDM), making FDM more efficient for rapid prototyping and large volume production. FDM printers deposit thermoplastic material layer-by-layer at faster rates, optimizing production speed while maintaining acceptable accuracy for many electronic components. Choosing between SLA and FDM depends on the balance between the need for fine detail and faster turnaround in electronics manufacturing.

Cost Analysis: SLA vs FDM

Stereolithography (SLA) typically incurs higher initial and operational costs due to expensive resin materials and maintenance of specialized laser equipment, whereas Fused Deposition Modeling (FDM) benefits from lower-cost thermoplastics and simpler hardware. The cost per part in SLA rises with increased surface finishing and resolution requirements, while FDM offers cost efficiency for larger, less detailed prototypes. Businesses prioritizing budget-friendly rapid prototyping commonly opt for FDM, whereas SLA suits applications demanding higher precision despite elevated expenses.

Applications in Electronics Prototyping

Stereolithography (SLA) offers high-resolution and smooth surface finishes ideal for producing intricate electronic enclosures and precise circuit board prototypes. Fused Deposition Modeling (FDM) excels in creating durable, functional parts with rapid turnaround, suitable for custom brackets, housings, and mechanical components in electronic devices. SLA's photopolymer resins enable detailed micro-features, while FDM's thermoplastics provide strength and flexibility necessary for testing and iterative design in electronics prototyping.

Choosing the Right 3D Printing Method for Electronics

Stereolithography (SLA) offers high-resolution prints with smooth surface finishes, ideal for producing intricate electronic component housings and prototypes requiring fine detail. Fused Deposition Modeling (FDM) provides cost-effective and durable parts suitable for functional electronic enclosures and larger structural components. Selecting between SLA and FDM depends on precision needs, material properties, and budget constraints within electronic device manufacturing.

Stereolithography vs Fused Deposition Modeling Infographic

productdif.com

productdif.com