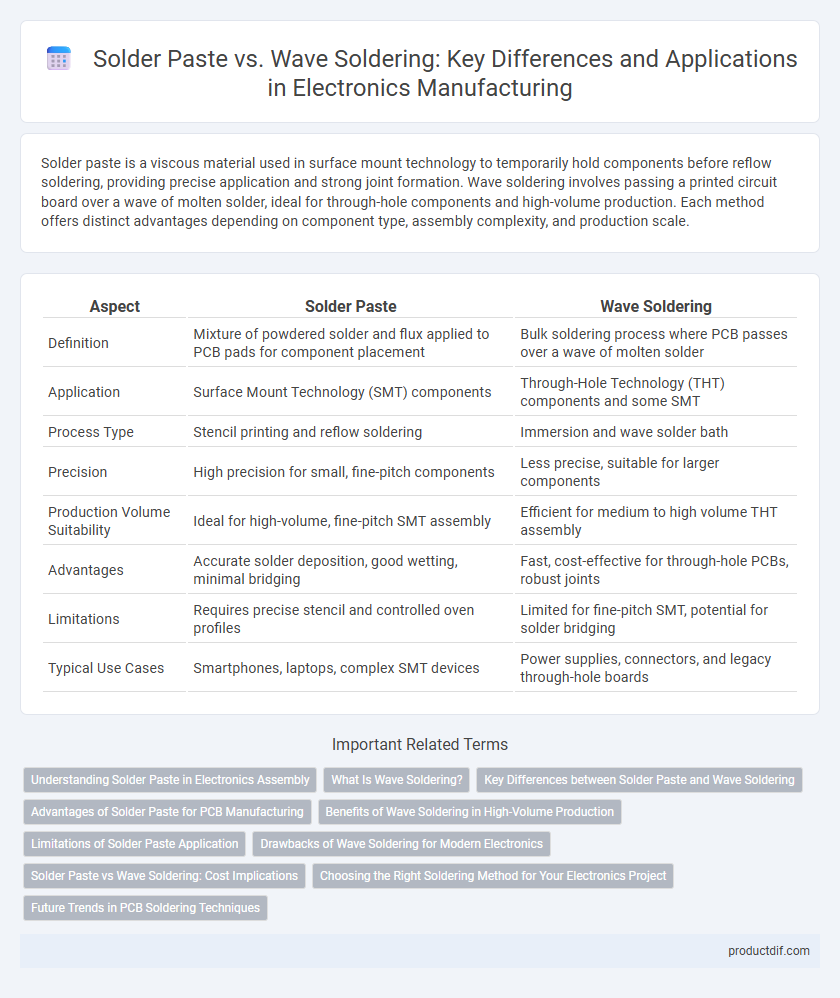

Solder paste is a viscous material used in surface mount technology to temporarily hold components before reflow soldering, providing precise application and strong joint formation. Wave soldering involves passing a printed circuit board over a wave of molten solder, ideal for through-hole components and high-volume production. Each method offers distinct advantages depending on component type, assembly complexity, and production scale.

Table of Comparison

| Aspect | Solder Paste | Wave Soldering |

|---|---|---|

| Definition | Mixture of powdered solder and flux applied to PCB pads for component placement | Bulk soldering process where PCB passes over a wave of molten solder |

| Application | Surface Mount Technology (SMT) components | Through-Hole Technology (THT) components and some SMT |

| Process Type | Stencil printing and reflow soldering | Immersion and wave solder bath |

| Precision | High precision for small, fine-pitch components | Less precise, suitable for larger components |

| Production Volume Suitability | Ideal for high-volume, fine-pitch SMT assembly | Efficient for medium to high volume THT assembly |

| Advantages | Accurate solder deposition, good wetting, minimal bridging | Fast, cost-effective for through-hole PCBs, robust joints |

| Limitations | Requires precise stencil and controlled oven profiles | Limited for fine-pitch SMT, potential for solder bridging |

| Typical Use Cases | Smartphones, laptops, complex SMT devices | Power supplies, connectors, and legacy through-hole boards |

Understanding Solder Paste in Electronics Assembly

Solder paste plays a crucial role in electronics assembly by providing a precise mixture of powdered solder and flux applied to PCB pads before component placement. Its formulation ensures strong mechanical bonds and reliable electrical connections during the reflow soldering process. Understanding solder paste viscosity, metal content, and flux activity is essential for optimizing print quality and minimizing defects in surface mount technology (SMT) production.

What Is Wave Soldering?

Wave soldering is a bulk soldering process used to connect electronic components to printed circuit boards (PCBs) by passing the board over a standing wave of molten solder. This technique ensures consistent solder joints on through-hole components, improving production speed and reliability in mass manufacturing. Wave soldering is ideal for high-volume assembly, offering precise control over solder application and effective heat transfer.

Key Differences between Solder Paste and Wave Soldering

Solder paste is a viscous mixture of powdered solder and flux used for precise surface mount technology (SMT) assembly, while wave soldering is a bulk process where a wave of molten solder connects through-hole components to PCB pads. Solder paste enables fine-pitch component placement with reflow ovens for temperature-controlled soldering, contrasting with wave soldering's efficiency for through-hole and mixed-technology boards. The key difference lies in application method and suitability: solder paste supports high-density, miniature SMT components, whereas wave soldering excels in mass production of through-hole assemblies.

Advantages of Solder Paste for PCB Manufacturing

Solder paste provides precise control over solder volume and placement, enhancing the accuracy of surface mount technology (SMT) assemblies on PCBs. Its ability to support fine-pitch components and complex circuit designs results in higher reliability and reduced defects compared to wave soldering. Solder paste also enables automated printing processes, improving production speed and consistency in electronic manufacturing.

Benefits of Wave Soldering in High-Volume Production

Wave soldering offers exceptional efficiency and uniformity in high-volume electronics manufacturing, significantly reducing assembly time compared to solder paste application. Its consistent solder joints enhance reliability and minimize defects, making it ideal for mass production of through-hole components. The automated process also lowers labor costs and ensures repeatable quality across large batches, improving overall production throughput.

Limitations of Solder Paste Application

Solder paste application faces limitations such as limited shelf life and sensitivity to humidity and temperature, which can degrade its performance over time. The process demands precise stencil printing and controlled reflow profiles to avoid defects like tombstoning and bridging. Additionally, solder paste is less effective for through-hole components, where wave soldering offers better penetration and wetting.

Drawbacks of Wave Soldering for Modern Electronics

Wave soldering presents significant drawbacks for modern electronics, including limited precision that leads to issues with fine-pitch components and surface-mount devices (SMDs). It also increases the risk of thermal damage to sensitive components due to excessive heat exposure during the wave process. Moreover, wave soldering is less adaptable to complex, high-density printed circuit boards (PCBs), resulting in reduced efficiency and higher defect rates compared to solder paste reflow methods.

Solder Paste vs Wave Soldering: Cost Implications

Solder paste offers lower upfront costs due to its compatibility with surface mount technology (SMT) and reduced material waste compared to wave soldering. Wave soldering incurs higher expenses from specialized equipment and maintenance but benefits from faster production in through-hole PCB assemblies. Choosing between solder paste and wave soldering depends on volume, PCB complexity, and long-term manufacturing cost efficiency.

Choosing the Right Soldering Method for Your Electronics Project

Choosing the right soldering method for your electronics project depends on factors such as project scale, component type, and desired precision. Solder paste is ideal for surface-mount technology (SMT) assemblies, offering precise application and compatibility with reflow soldering processes. Wave soldering suits through-hole components and high-volume production, providing rapid soldering but less control over fine-pitch parts.

Future Trends in PCB Soldering Techniques

Emerging PCB soldering trends emphasize the integration of advanced materials like lead-free and nano-enhanced solder paste to improve joint reliability and environmental compliance. Wave soldering continues evolving through selective wave technology and enhanced flux formulations, enabling precise solder application and reduced defects for complex boards. Combining machine learning and real-time process monitoring accelerates optimization between solder paste reflow and wave soldering, driving higher yield and efficiency in electronics manufacturing.

Solder Paste vs Wave Soldering Infographic

productdif.com

productdif.com