Heat sinks dissipate heat from electronic components using metal fins to increase surface area, offering reliable and low-maintenance cooling for CPUs and GPUs. Liquid cooling systems circulate coolant through a closed loop to absorb and transfer heat away, providing superior thermal performance and quieter operation ideal for overclocked or high-performance setups. Choosing between heat sinks and liquid cooling depends on the balance of efficiency, noise levels, and system complexity desired.

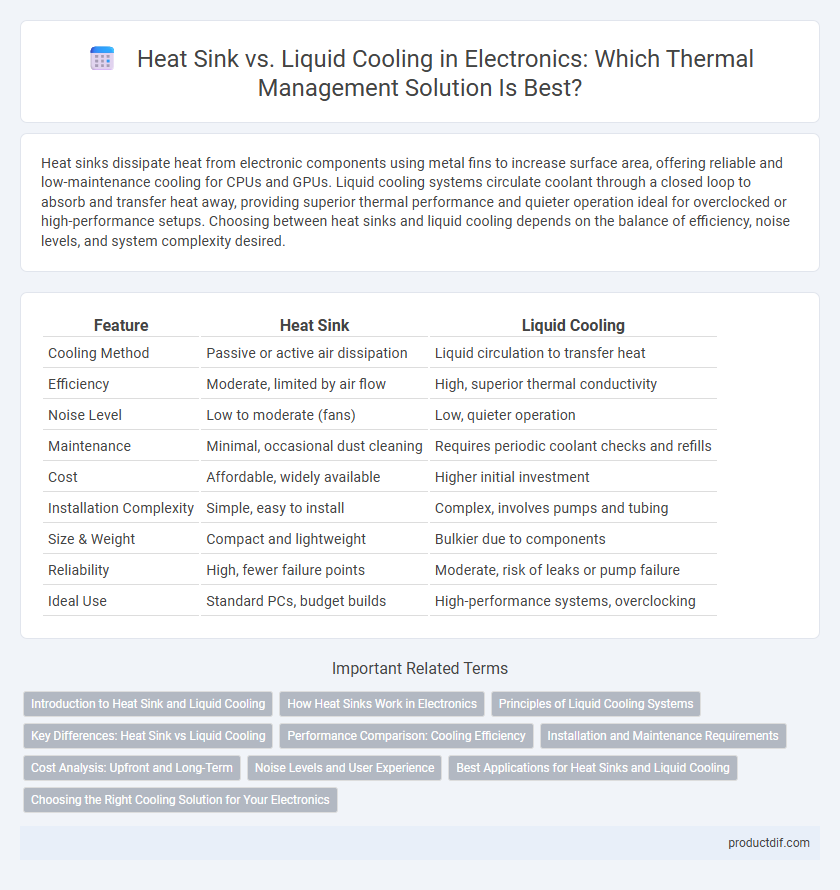

Table of Comparison

| Feature | Heat Sink | Liquid Cooling |

|---|---|---|

| Cooling Method | Passive or active air dissipation | Liquid circulation to transfer heat |

| Efficiency | Moderate, limited by air flow | High, superior thermal conductivity |

| Noise Level | Low to moderate (fans) | Low, quieter operation |

| Maintenance | Minimal, occasional dust cleaning | Requires periodic coolant checks and refills |

| Cost | Affordable, widely available | Higher initial investment |

| Installation Complexity | Simple, easy to install | Complex, involves pumps and tubing |

| Size & Weight | Compact and lightweight | Bulkier due to components |

| Reliability | High, fewer failure points | Moderate, risk of leaks or pump failure |

| Ideal Use | Standard PCs, budget builds | High-performance systems, overclocking |

Introduction to Heat Sink and Liquid Cooling

Heat sinks are passive cooling devices designed to dissipate heat from electronic components by increasing surface area and enhancing airflow, typically made from aluminum or copper for high thermal conductivity. Liquid cooling systems utilize a coolant circulated through tubes and a radiator to efficiently transfer heat away from critical components, offering superior thermal management for high-performance electronics. Comparing both, heat sinks provide simplicity and reliability, while liquid cooling delivers enhanced cooling capacity for demanding applications.

How Heat Sinks Work in Electronics

Heat sinks dissipate heat from electronic components by transferring thermal energy from the device to the surrounding air through conduction and convection. They are typically made from metals like aluminum or copper, which have high thermal conductivity to efficiently absorb and spread heat. The fins on a heat sink increase the surface area, enhancing airflow and accelerating heat dissipation to maintain optimal operating temperatures in electronics.

Principles of Liquid Cooling Systems

Liquid cooling systems operate by circulating a coolant through tubes that absorb heat from electronic components and transport it to a radiator, where the heat dissipates into the surrounding air. These systems rely on principles of fluid dynamics and thermodynamics to enhance heat transfer efficiency compared to traditional heat sinks, which dissipate heat passively through metal fins. By actively moving heat away from critical components, liquid cooling maintains lower temperatures, reduces thermal resistance, and supports higher performance and longer lifespan of electronics.

Key Differences: Heat Sink vs Liquid Cooling

Heat sinks rely on passive or active airflow to dissipate heat from electronic components, using materials like aluminum or copper with fins to maximize surface area and thermal conductivity. Liquid cooling employs coolant circulated through tubes and a radiator, offering superior heat transfer efficiency and better temperature regulation for high-performance or overclocked processors. Key differences include heat sinks' simplicity, lower cost, and ease of installation versus liquid cooling's enhanced cooling capacity, reduced noise levels, and increased complexity and maintenance requirements.

Performance Comparison: Cooling Efficiency

Heat sink cooling efficiency depends on thermal conductivity and surface area, effectively dissipating heat in low to moderate power electronics. Liquid cooling systems outperform heat sinks by offering higher thermal transfer rates and uniform temperature control, ideal for high-performance CPUs and GPUs. Enhanced heat dissipation in liquid cooling reduces thermal throttling and improves overall system stability under heavy workloads.

Installation and Maintenance Requirements

Heat sinks offer straightforward installation with minimal tools, requiring only thermal paste application and secure attachment to the component, making them ideal for users seeking low-maintenance cooling solutions. Liquid cooling systems demand more complex installation involving pump, radiator, and tubing setup, increased attention to leak prevention, and periodic coolant refills or replacements. Maintenance for heat sinks generally involves occasional dust cleaning, while liquid cooling requires regular system checks to ensure pump functionality and fluid integrity, impacting long-term upkeep considerations.

Cost Analysis: Upfront and Long-Term

Heat sinks offer a lower upfront cost due to their simple design and widespread availability, making them a budget-friendly choice for standard electronics cooling. Liquid cooling systems require higher initial investment for components like pumps, radiators, and coolant but can provide improved thermal performance, potentially reducing long-term costs by extending hardware lifespan and enhancing energy efficiency. Evaluating total cost of ownership involves balancing upfront expenses against maintenance, potential system downtime, and efficiency gains in various electronic applications.

Noise Levels and User Experience

Heat sinks provide passive cooling with minimal noise, making them ideal for users prioritizing silent operation. Liquid cooling systems, while often more efficient at heat dissipation, can produce noticeable pump and fan noise that may affect user experience in quiet environments. Choosing between heat sink and liquid cooling depends on balancing thermal performance with acceptable noise levels for the intended application.

Best Applications for Heat Sinks and Liquid Cooling

Heat sinks are best suited for low to moderate power electronics such as CPUs in laptops, power supplies, and LED lighting where passive cooling suffices and compact design is crucial. Liquid cooling excels in high-performance systems like gaming PCs, data centers, and industrial equipment requiring efficient heat dissipation from overclocked processors or GPUs to maintain stability and prolong component lifespan. Selecting between heat sinks and liquid cooling depends on power density, space constraints, and thermal management needs.

Choosing the Right Cooling Solution for Your Electronics

Selecting the ideal cooling solution for electronics depends on factors such as thermal load, space constraints, and noise tolerance. Heat sinks offer reliable passive cooling with ease of installation, making them suitable for low to moderate heat dissipation. Liquid cooling systems excel in handling high-performance devices by providing efficient heat transfer and maintaining lower operating temperatures, especially in compact or high-power environments.

Heat Sink vs Liquid Cooling Infographic

productdif.com

productdif.com