Flux soldering employs a chemical flux to remove oxidation and improve metal adhesion during manual or wave soldering processes, making it ideal for through-hole components and repair work. Reflow soldering uses controlled heating in an oven or hot air system to melt solder paste applied on surface mount devices, ensuring precision and consistency for mass production. Choosing between flux and reflow soldering depends on the type of components, production volume, and desired solder joint quality in electronic assembly.

Table of Comparison

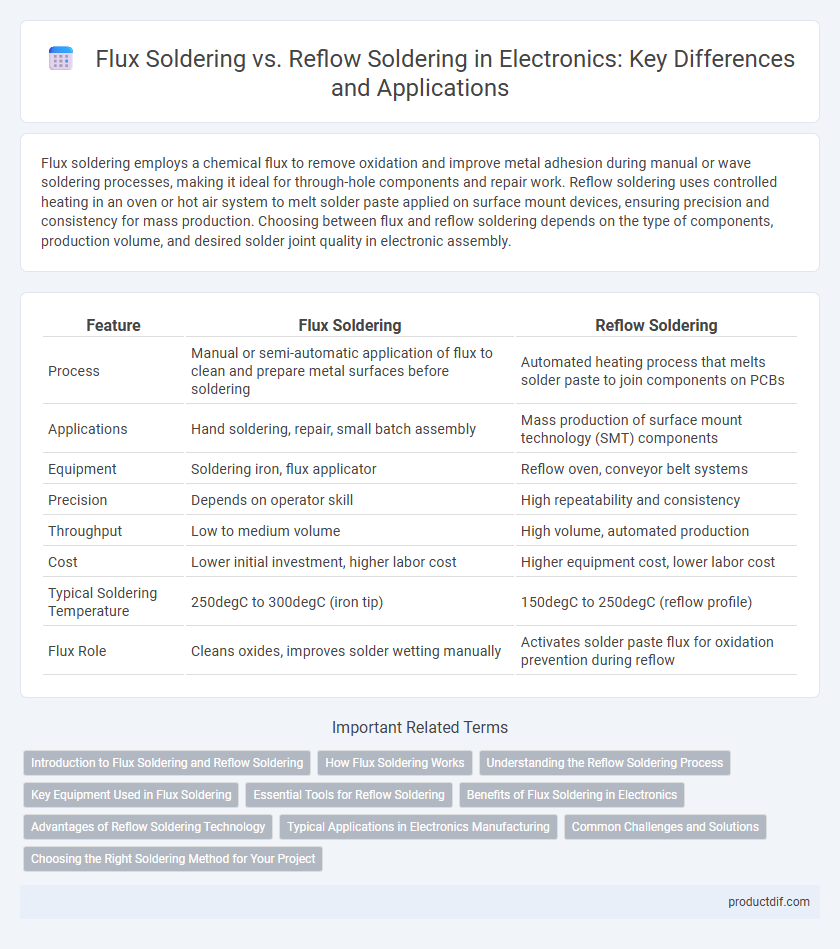

| Feature | Flux Soldering | Reflow Soldering |

|---|---|---|

| Process | Manual or semi-automatic application of flux to clean and prepare metal surfaces before soldering | Automated heating process that melts solder paste to join components on PCBs |

| Applications | Hand soldering, repair, small batch assembly | Mass production of surface mount technology (SMT) components |

| Equipment | Soldering iron, flux applicator | Reflow oven, conveyor belt systems |

| Precision | Depends on operator skill | High repeatability and consistency |

| Throughput | Low to medium volume | High volume, automated production |

| Cost | Lower initial investment, higher labor cost | Higher equipment cost, lower labor cost |

| Typical Soldering Temperature | 250degC to 300degC (iron tip) | 150degC to 250degC (reflow profile) |

| Flux Role | Cleans oxides, improves solder wetting manually | Activates solder paste flux for oxidation prevention during reflow |

Introduction to Flux Soldering and Reflow Soldering

Flux soldering utilizes a chemical agent to remove oxidation and improve wetting during the soldering process, ensuring strong, reliable electrical connections. Reflow soldering involves melting solder paste applied to components on a PCB by passing it through a controlled heat profile, allowing for precise and automated assembly of surface-mount devices. Both methods are essential in electronics manufacturing but differ significantly in technique, application, and efficiency.

How Flux Soldering Works

Flux soldering works by applying a chemical flux to the metal surfaces before heating, which removes oxides and prevents further oxidation during the soldering process, ensuring a clean, strong bond. The flux acts as a cleaning agent and improves the wetting properties of the molten solder, allowing it to flow evenly and adhere properly to the components and PCB pads. This method is typically used for manual soldering tasks in electronics assembly, providing precise control over solder application and heat.

Understanding the Reflow Soldering Process

Reflow soldering involves the precise application of heat to melt solder paste, creating strong electrical connections on printed circuit boards (PCBs) by allowing the solder to flow and solidify around component leads. Temperature profiles are critical, typically including preheat, soak, reflow, and cooling stages to ensure optimal solder joint quality and prevent thermal damage to components. Unlike flux soldering, reflow soldering integrates flux within the solder paste, improving oxidation control and enhancing joint reliability in automated assembly lines.

Key Equipment Used in Flux Soldering

Flux soldering primarily utilizes essential equipment such as flux dispensers, solder pots, and manual soldering irons to ensure precise application and controlled solder flow. Flux dispensers apply flux accurately to the target areas, enhancing solder wetting and adhesion on electronic components. The solder pot maintains molten solder at a stable temperature, while manual soldering irons provide direct heat for component attachment and flow control.

Essential Tools for Reflow Soldering

Essential tools for reflow soldering include a precise reflow oven or hot air rework station, solder paste, and a stencil for accurate paste application. Temperature controllers and thermocouples ensure proper thermal profiles to avoid component damage and achieve reliable solder joints. Additionally, inspection equipment such as microscopes and X-ray machines help verify solder quality and detect defects in high-density PCB assemblies.

Benefits of Flux Soldering in Electronics

Flux soldering enhances the wetting and bonding of solder to electronic components by removing oxides and contaminants from metal surfaces, ensuring strong mechanical and electrical connections. It allows for precise application and better control over the soldering process, minimizing thermal stress and damage to sensitive components. Flux soldering also improves solder joint reliability and prevents defects such as cold joints and solder bridges, which are critical in high-density circuit assemblies.

Advantages of Reflow Soldering Technology

Reflow soldering technology offers precise temperature control, reducing the risk of component damage during assembly. It enables consistent solder joint quality and supports high-volume production with automated processes. The method also allows for efficient handling of small and complex surface-mount devices, enhancing overall manufacturing reliability.

Typical Applications in Electronics Manufacturing

Flux soldering is commonly used in through-hole technology and manual assembly processes, where precise control over solder flow is essential for components with leads. Reflow soldering dominates surface-mount technology (SMT) production lines, enabling efficient and consistent soldering of small, densely packed components on PCBs. Typical applications for reflow soldering include consumer electronics, automotive control units, and mobile devices requiring high-volume, automated assembly.

Common Challenges and Solutions

Flux soldering often faces challenges with residue contamination affecting circuit performance, which can be mitigated by using no-clean flux formulations and thorough cleaning processes. Reflow soldering presents issues such as thermal stress and component misalignment, addressed through precise temperature profiling and automated pick-and-place equipment. Both methods require careful control of solder paste composition and deposition to ensure strong mechanical and electrical connections.

Choosing the Right Soldering Method for Your Project

Flux soldering is ideal for manual or small-scale electronics assembly, offering precise control and effective oxidation prevention, while reflow soldering excels in high-volume production with consistent temperature profiles for uniform solder joints. When choosing the right soldering method, consider project scale, component sensitivity, and production speed requirements to optimize assembly quality and cost efficiency. Evaluating factors like thermal profile compatibility and solder paste type ensures the selected method aligns with your electronics manufacturing goals.

Flux Soldering vs Reflow Soldering Infographic

productdif.com

productdif.com