Power MOSFETs offer faster switching speeds and higher efficiency at low voltage levels, making them ideal for high-frequency applications. IGBTs provide better performance in high-voltage, high-current scenarios with lower conduction losses, suited for industrial motor drives and power inverters. Choosing between Power MOSFETs and IGBTs depends on voltage, current requirements, and switching frequency of the electronic system.

Table of Comparison

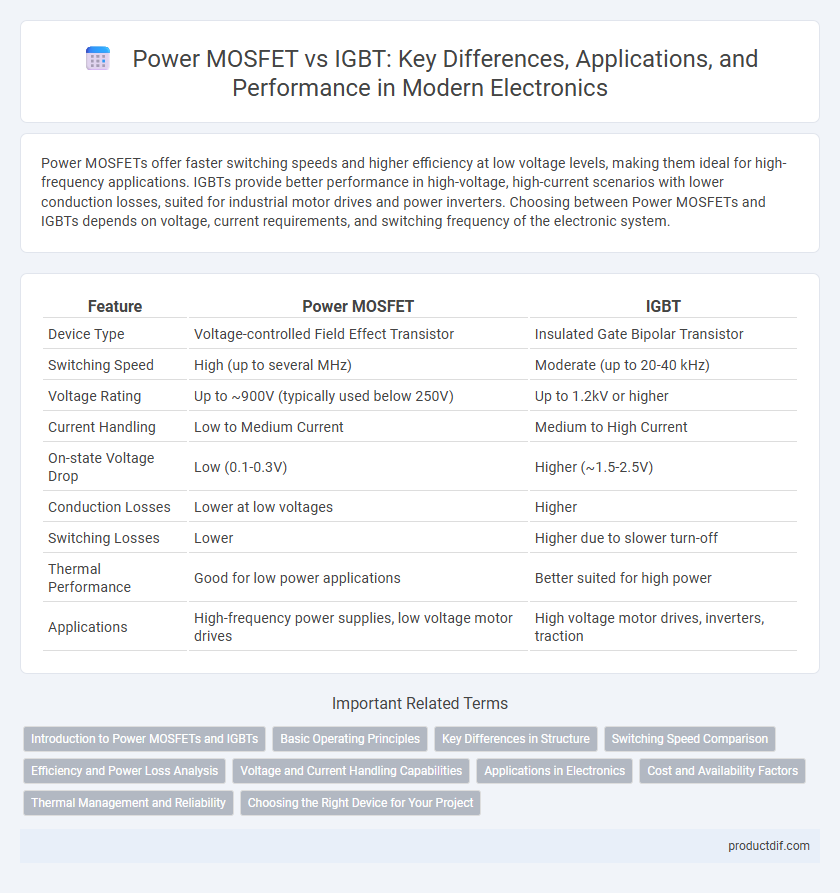

| Feature | Power MOSFET | IGBT |

|---|---|---|

| Device Type | Voltage-controlled Field Effect Transistor | Insulated Gate Bipolar Transistor |

| Switching Speed | High (up to several MHz) | Moderate (up to 20-40 kHz) |

| Voltage Rating | Up to ~900V (typically used below 250V) | Up to 1.2kV or higher |

| Current Handling | Low to Medium Current | Medium to High Current |

| On-state Voltage Drop | Low (0.1-0.3V) | Higher (~1.5-2.5V) |

| Conduction Losses | Lower at low voltages | Higher |

| Switching Losses | Lower | Higher due to slower turn-off |

| Thermal Performance | Good for low power applications | Better suited for high power |

| Applications | High-frequency power supplies, low voltage motor drives | High voltage motor drives, inverters, traction |

Introduction to Power MOSFETs and IGBTs

Power MOSFETs and IGBTs are essential semiconductor devices used for switching and amplifying electronic signals in power electronics. Power MOSFETs offer fast switching speeds and high efficiency, making them ideal for low-voltage, high-frequency applications, while IGBTs excel in handling higher voltages and currents with lower conduction losses in medium to high-power scenarios. Both devices are crucial in inverter circuits, motor drives, and power supply units, with their unique advantages tailored to specific industrial needs.

Basic Operating Principles

Power MOSFETs operate through voltage-controlled conduction channels formed in a semiconductor by applying voltage to the gate terminal, allowing for fast switching and low on-resistance. IGBTs combine the gate-controlled input of MOSFETs with the bipolar conduction mechanism, providing high current capability and low saturation voltage for efficient high-power switching. The choice between Power MOSFET and IGBT depends on switching frequency and voltage requirements, with MOSFETs preferred for high-speed, low-voltage applications and IGBTs suited for high-voltage, high-current operations.

Key Differences in Structure

Power MOSFETs feature a unipolar structure relying on majority carriers, which enables faster switching and lower conduction losses at low voltages. IGBTs combine a MOS gate with a bipolar transistor structure, incorporating both majority and minority carriers, resulting in higher voltage handling and better conduction at high power levels. The intrinsic design of MOSFETs favors low-voltage applications, while IGBTs excel in high-voltage, high-current environments due to their layered semiconductor architecture.

Switching Speed Comparison

Power MOSFETs exhibit significantly faster switching speeds than Insulated Gate Bipolar Transistors (IGBTs), often reaching switching frequencies in the hundreds of kilohertz to megahertz range. The lower gate charge and absence of minority carrier injection in MOSFETs contribute to reduced turn-on and turn-off times, making them ideal for high-frequency applications. Conversely, IGBTs, though efficient in handling higher voltage and current, generally switch at slower rates due to their bipolar conduction mechanism and inherent tail current during turn-off.

Efficiency and Power Loss Analysis

Power MOSFETs exhibit lower conduction losses at low to medium voltage ranges due to their majority carrier operation, resulting in higher efficiency for high-frequency switching applications. IGBTs, combining MOS gate control with bipolar conduction, offer lower switching losses in high-voltage, high-current environments but suffer from tail current losses that increase overall power dissipation. Efficiency optimization in power electronics requires balancing MOSFETs' fast switching capability and IGBTs' superior performance under high voltage and current conditions to minimize thermal losses and enhance system reliability.

Voltage and Current Handling Capabilities

Power MOSFETs excel in low to medium voltage applications, typically handling voltages up to 250V with fast switching speeds and high efficiency in low current ranges. IGBTs are preferred for high voltage and high current scenarios, supporting voltages from 600V to over 6,500V and currents exceeding hundreds of amps, making them suitable for heavy industrial equipment. The choice depends on the required voltage rating and current load, with MOSFETs favored for efficiency in switching circuits and IGBTs for robust power control in high-voltage systems.

Applications in Electronics

Power MOSFETs excel in high-frequency switching applications such as DC-DC converters, RF amplifiers, and low-voltage power supplies due to their fast switching speed and low gate charge. IGBTs are preferred in high-voltage, high-current applications like motor drives, induction heating, and renewable energy inverters because they combine MOSFET input characteristics with bipolar transistor output capabilities. The choice between Power MOSFET and IGBT depends on the trade-off between switching efficiency and voltage-current handling requirements in electronic systems.

Cost and Availability Factors

Power MOSFETs generally offer lower initial costs and broader availability due to their widespread use in low to medium voltage applications and simpler manufacturing processes. IGBTs, while more expensive, are preferred in high voltage and high current scenarios, resulting in higher device costs and more specialized supply chains. Market demand and application-specific requirements heavily influence the cost-effectiveness and availability of these semiconductor devices.

Thermal Management and Reliability

Power MOSFETs exhibit lower thermal resistance and faster switching speeds, enabling efficient heat dissipation and improved thermal management in high-frequency applications. IGBTs, while able to handle higher voltage and current levels with robust ruggedness, generate more heat and require advanced cooling solutions to enhance reliability under high-power conditions. Effective thermal design, including heat sinks and optimized packaging, is critical for extending the lifespan and maintaining the performance of both Power MOSFETs and IGBTs in electronic circuits.

Choosing the Right Device for Your Project

Power MOSFETs excel in high-speed switching and low voltage applications, making them ideal for projects requiring fast response and efficiency under 200V. IGBTs are better suited for high voltage and high current scenarios above 600V, offering robust performance in industrial motor drives and power inverters. Selecting the right device depends on operating voltage, switching frequency, and thermal management constraints specific to your electronics project.

Power MOSFET vs IGBT Infographic

productdif.com

productdif.com