PCB prototyping involves creating a preliminary version of a printed circuit board to test design functionality and identify potential errors before mass production. PCB manufacturing focuses on large-scale production, ensuring consistency, durability, and compliance with industry standards for final products. Rapid prototyping accelerates development cycles, while manufacturing emphasizes precision and cost-effectiveness for bulk orders.

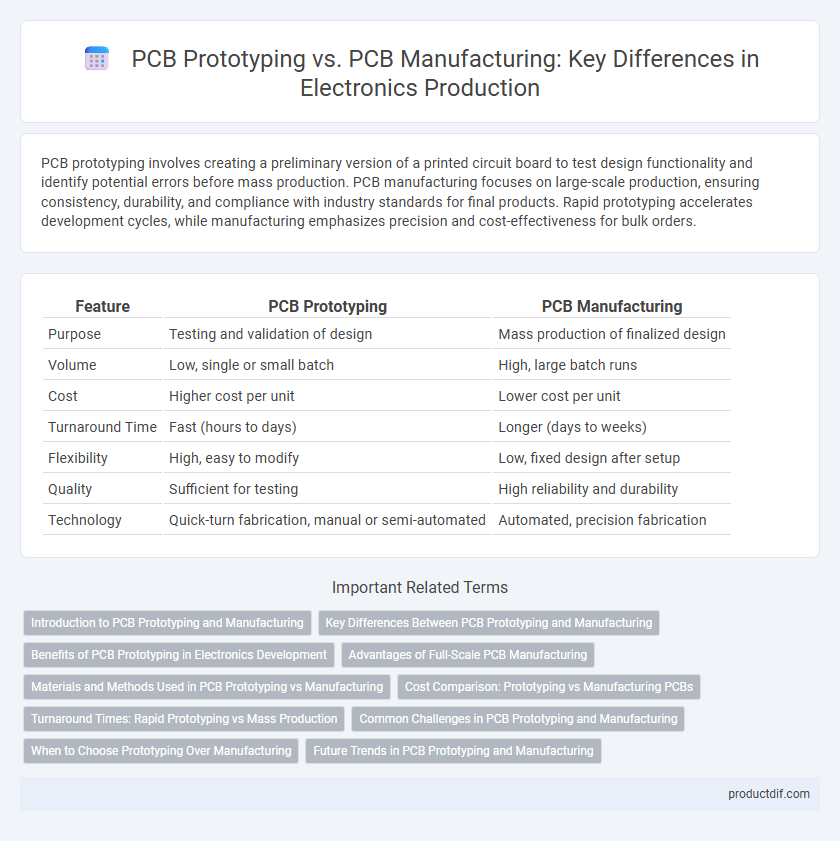

Table of Comparison

| Feature | PCB Prototyping | PCB Manufacturing |

|---|---|---|

| Purpose | Testing and validation of design | Mass production of finalized design |

| Volume | Low, single or small batch | High, large batch runs |

| Cost | Higher cost per unit | Lower cost per unit |

| Turnaround Time | Fast (hours to days) | Longer (days to weeks) |

| Flexibility | High, easy to modify | Low, fixed design after setup |

| Quality | Sufficient for testing | High reliability and durability |

| Technology | Quick-turn fabrication, manual or semi-automated | Automated, precision fabrication |

Introduction to PCB Prototyping and Manufacturing

PCB prototyping involves creating initial circuit board samples to test designs, validate functionality, and identify potential issues before mass production. PCB manufacturing focuses on producing large volumes of fully tested, high-quality circuit boards using standardized industrial processes such as photolithography, etching, and solder mask application. Prototype PCBs often use rapid fabrication methods like CNC milling or 3D printing, while manufacturing employs optimized workflows for cost efficiency and consistency in electronics production.

Key Differences Between PCB Prototyping and Manufacturing

PCB prototyping involves creating a small batch or single unit of a printed circuit board to test design functionality and identify potential issues before full-scale production. Manufacturing, in contrast, is the large-scale production process that prioritizes consistency, quality control, and cost efficiency for mass distribution. Key differences include turnaround time, with prototyping being faster for design validation, and manufacturing requiring extensive process optimization for volume output.

Benefits of PCB Prototyping in Electronics Development

PCB prototyping accelerates electronics development by enabling rapid testing and design validation, reducing costly errors before full-scale manufacturing. It allows engineers to iterate circuit layouts, evaluate functionality, and optimize component placement with real-world feedback. This process minimizes risks, saves production costs, and shortens time-to-market for innovative electronic products.

Advantages of Full-Scale PCB Manufacturing

Full-scale PCB manufacturing ensures consistent quality and higher production volumes, reducing per-unit costs significantly compared to prototyping. This process leverages advanced automated machinery to achieve precise layer alignment and reliable electrical performance tailored for mass production. Manufacturers benefit from enhanced design reproducibility and faster turnaround times, supporting large-scale deployment in complex electronics applications.

Materials and Methods Used in PCB Prototyping vs Manufacturing

PCB prototyping primarily uses low-cost materials like FR-4 or phenolic substrates and employs methods such as CNC milling, laser etching, or manual soldering to quickly validate designs. In contrast, PCB manufacturing utilizes high-quality materials including high Tg FR-4, polyimide, or Rogers substrates combined with advanced automated processes like photolithography, chemical etching, and wave soldering for mass production. The precision and consistency of manufacturing techniques ensure superior electrical performance and durability compared to the flexible, faster approaches in prototyping.

Cost Comparison: Prototyping vs Manufacturing PCBs

PCB prototyping typically incurs higher per-unit costs due to small batch sizes and rapid turnaround requirements, whereas PCB manufacturing benefits from economies of scale, significantly lowering the cost per unit in large production runs. Prototyping costs include setup fees and specialized equipment use, while manufacturing costs are distributed across mass-produced quantities, reducing individual PCB expenses. For startups and small projects, prototyping offers affordable flexibility despite higher initial costs, while manufacturing is more cost-effective for high-volume orders and long-term production.

Turnaround Times: Rapid Prototyping vs Mass Production

PCB prototyping offers rapid turnaround times, often delivering functional boards within days to weeks, essential for iterative design testing and quick validation. In contrast, PCB manufacturing for mass production involves longer lead times due to stringent quality controls, large batch processing, and supply chain coordination, typically ranging from weeks to months. The speed difference directly impacts project timelines, with prototyping enabling fast innovation cycles while manufacturing prioritizes consistency and volume scalability.

Common Challenges in PCB Prototyping and Manufacturing

PCB prototyping often faces challenges such as design errors, limited material options, and longer iteration times, which can delay product development. In PCB manufacturing, common issues include maintaining consistent quality across mass production, managing supply chain constraints, and ensuring precise component placement and soldering. Both stages require stringent testing and validation to mitigate risks like signal integrity problems and mechanical failures.

When to Choose Prototyping Over Manufacturing

PCB prototyping is essential when new electronic designs require testing and validation before full-scale production, enabling detection of design flaws and functional issues early in development. It is preferred for small batch production runs, proof-of-concept models, and iterative design improvements that demand flexibility and rapid turnaround times. Choose prototyping over manufacturing when tight deadlines, cost constraints, or evolving designs necessitate quick adjustments without the high setup costs associated with mass manufacturing.

Future Trends in PCB Prototyping and Manufacturing

Advancements in PCB prototyping leverage AI-driven design automation and rapid 3D printing technologies, streamlining iteration cycles and enhancing precision at reduced costs. Emerging manufacturing techniques integrate flexible substrates and embedded components, enabling compact, high-performance electronics tailored for IoT, wearable devices, and automotive applications. Sustainable materials and additive manufacturing processes are increasingly adopted to minimize environmental impact while boosting scalability and production speed in next-generation PCB fabrication.

PCB Prototyping vs PCB Manufacturing Infographic

productdif.com

productdif.com