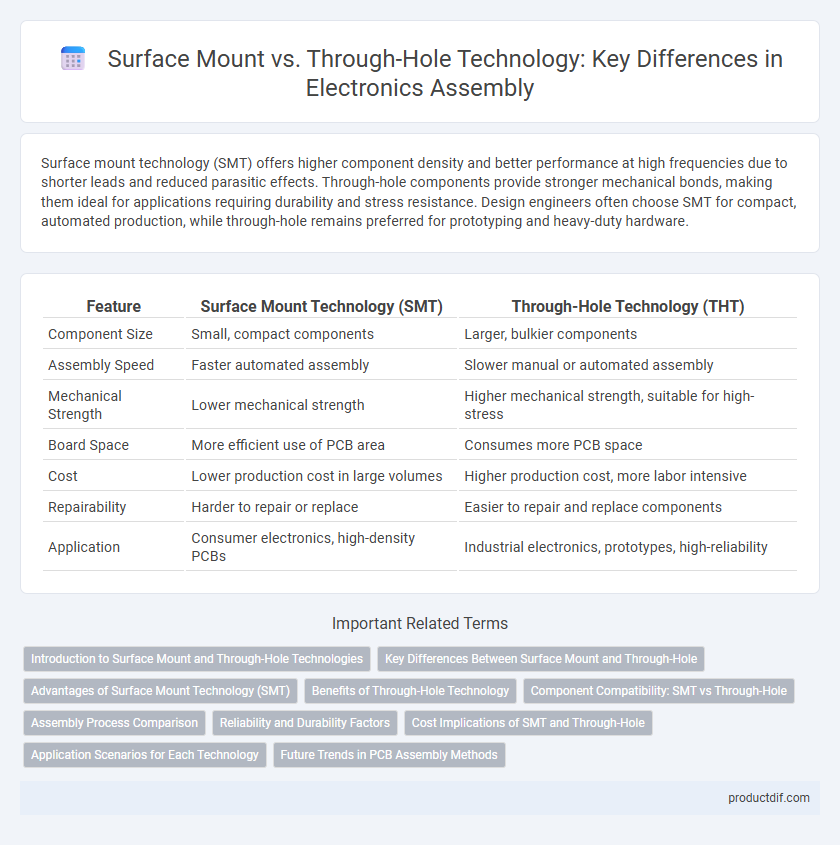

Surface mount technology (SMT) offers higher component density and better performance at high frequencies due to shorter leads and reduced parasitic effects. Through-hole components provide stronger mechanical bonds, making them ideal for applications requiring durability and stress resistance. Design engineers often choose SMT for compact, automated production, while through-hole remains preferred for prototyping and heavy-duty hardware.

Table of Comparison

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Small, compact components | Larger, bulkier components |

| Assembly Speed | Faster automated assembly | Slower manual or automated assembly |

| Mechanical Strength | Lower mechanical strength | Higher mechanical strength, suitable for high-stress |

| Board Space | More efficient use of PCB area | Consumes more PCB space |

| Cost | Lower production cost in large volumes | Higher production cost, more labor intensive |

| Repairability | Harder to repair or replace | Easier to repair and replace components |

| Application | Consumer electronics, high-density PCBs | Industrial electronics, prototypes, high-reliability |

Introduction to Surface Mount and Through-Hole Technologies

Surface mount technology (SMT) involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), enabling higher component density and automated assembly. Through-hole technology requires inserting component leads into drilled holes on the PCB, providing stronger mechanical bonds ideal for components exposed to mechanical stress. SMT dominates modern electronics manufacturing due to its space-saving advantages and compatibility with high-speed production techniques.

Key Differences Between Surface Mount and Through-Hole

Surface mount technology (SMT) places components directly on the surface of printed circuit boards (PCBs), enabling higher component density and more efficient automated assembly compared to through-hole technology, which requires leads to be inserted into drilled holes. Through-hole components offer superior mechanical strength and are preferred for high-stress applications, while SMT components allow for smaller design footprints and better high-frequency performance. Key differences include assembly process complexity, component size, mechanical durability, and suitability for automated production lines.

Advantages of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) enables higher component density on printed circuit boards, improving circuit performance and reducing overall device size. SMT components offer better electrical characteristics due to shorter lead lengths, enhancing signal integrity and high-frequency response. Manufacturing processes benefit from automation compatibility, which increases production speed and reduces labor costs compared to through-hole technology.

Benefits of Through-Hole Technology

Through-hole technology provides superior mechanical strength and durability, making it ideal for components subject to physical stress or vibration. It allows for easier prototyping and manual assembly, especially in low-volume production or repair scenarios. Enhanced electrical connectivity and reliability in high-power applications are other significant advantages of through-hole mounting.

Component Compatibility: SMT vs Through-Hole

Surface Mount Technology (SMT) components are designed for compact PCB layouts, offering higher component density and compatibility with automated assembly processes, unlike through-hole components that require larger pads and hole drilling. Through-hole components provide stronger mechanical bonds, making them suitable for connectors and components subjected to mechanical stress, but their bulkier size limits high-density designs. SMT is favored for modern electronics due to its compatibility with miniaturization and automated manufacturing, whereas through-hole remains essential for prototypes and applications requiring robust physical connections.

Assembly Process Comparison

The assembly process for Surface Mount Technology (SMT) involves placing components directly onto the PCB surface using automated machines, allowing for higher component density and faster production rates compared to Through-Hole Technology (THT). Through-Hole assembly requires inserting component leads into drilled holes on the PCB, followed by manual or wave soldering, which is more labor-intensive and time-consuming. SMT's precision pick-and-place machines and reflow soldering offer improved efficiency and scalability in modern electronics manufacturing.

Reliability and Durability Factors

Surface mount technology (SMT) offers higher reliability in electronics due to shorter lead lengths, which reduce inductance and improve signal integrity, thereby minimizing failure rates. Through-hole components provide superior mechanical strength, making them more durable in applications subject to mechanical stress or thermal cycling. Reliability in SMT can be enhanced by advanced soldering techniques and robust PCB design, while through-hole assemblies excel in high-vibration or heavy-load environments.

Cost Implications of SMT and Through-Hole

Surface Mount Technology (SMT) reduces manufacturing costs by enabling smaller component sizes and higher circuit densities, which lower material usage and allow faster automated assembly processes. Through-Hole Assembly incurs higher expenses due to larger components, more complex drilling requirements, and increased labor costs from manual or semi-automated insertion. SMT's cost-efficiency is favored in high-volume production, while Through-Hole remains viable for prototypes or circuits requiring mechanical strength despite higher per-unit costs.

Application Scenarios for Each Technology

Surface mount technology (SMT) excels in high-density circuit boards found in smartphones, laptops, and advanced consumer electronics due to its compact size and automated assembly benefits. Through-hole technology remains preferred for applications requiring strong mechanical bonds, such as connectors, transformers, and automotive or aerospace electronics subjected to high stress and vibration. Industrial equipment and prototyping stages often utilize through-hole components for easier manual soldering and rework compared to the precision required by SMT.

Future Trends in PCB Assembly Methods

Surface mount technology (SMT) continues to dominate PCB assembly due to its miniaturization capabilities and efficiency in automated production. Emerging trends highlight the integration of advanced materials and 3D printing techniques to enhance component density and reliability. Through-hole methods, while declining in general use, remain critical for high-strength mechanical connections and specialized applications in aerospace and automotive electronics.

Surface Mount vs Through-Hole Infographic

productdif.com

productdif.com